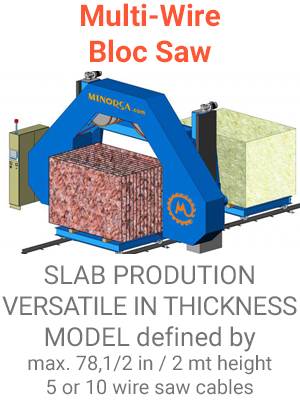

Multi-Material Wire Saw With Vertical Wheels

About

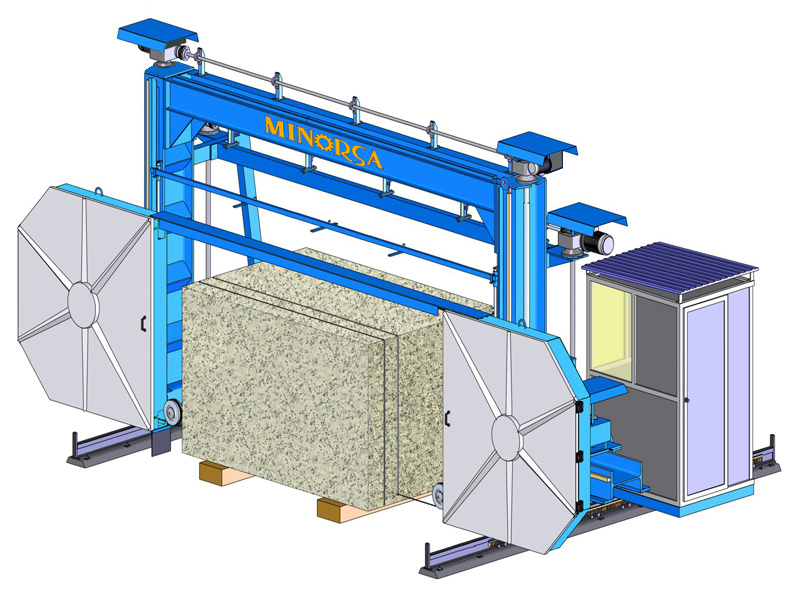

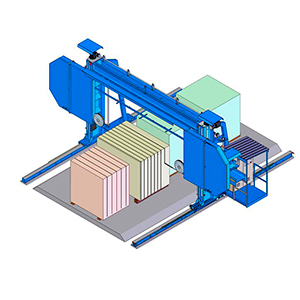

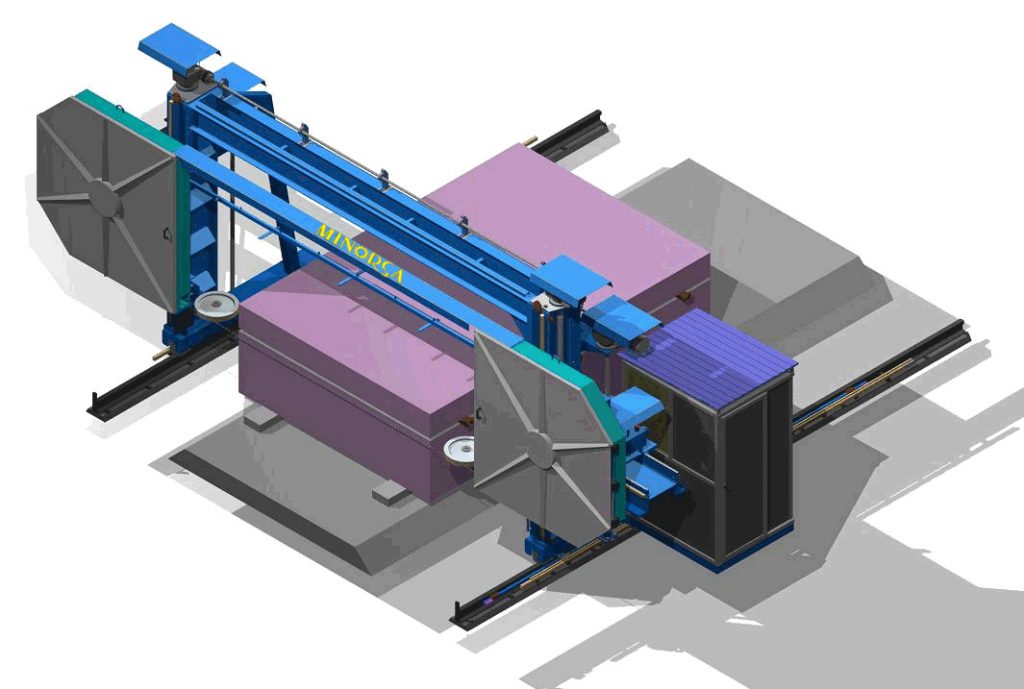

Allows cutting several blocks of different dimensions and stone types simultaneously. Greater cut capacity using less space, no need for huge foundations.

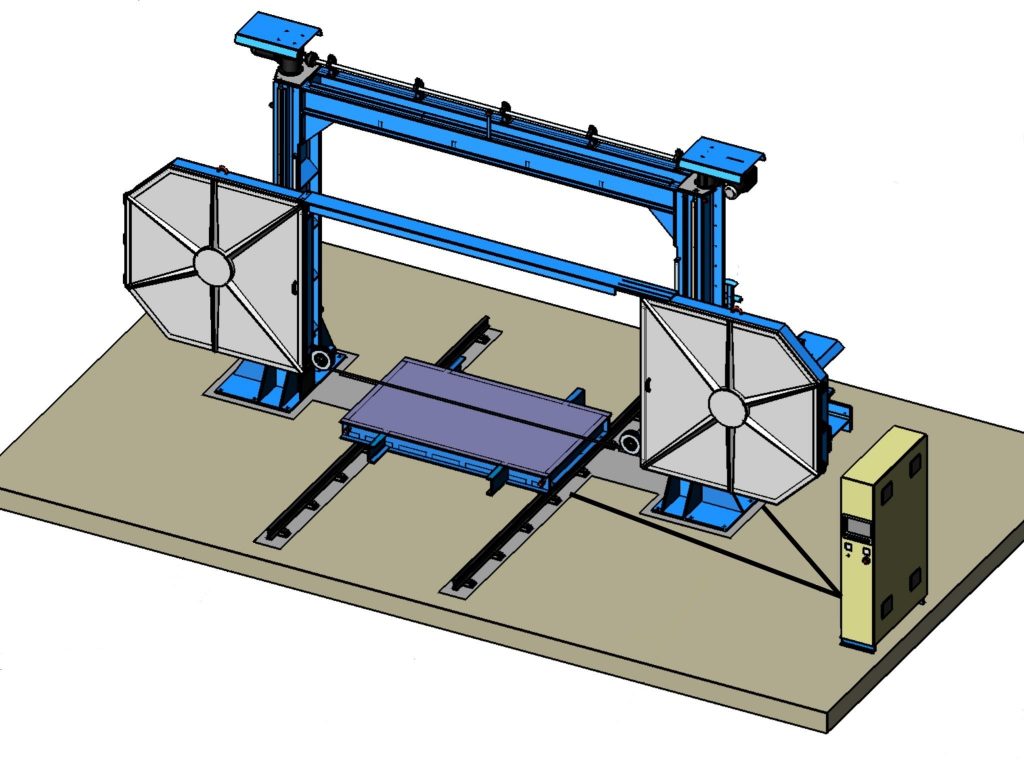

The Gantry structure allow an perfect union of all components, since the lateral twin pillars connected over creating an perfect ring, that supports the vertical travel shafts connected into the wheels, that ones are moved by gearbox to allow the slow displacement on cutting process and also improves the fast velocity to make the repositioning.

Theres dual ways to displace on measures, over an portico system moves on rails or with the monoframe fixed and an moving bench.

Can be used to multi materials cutting process, the wire speed can be change by the inverter and the easy open of the doors allow an fast and easy change of the diamond wire if necessary.

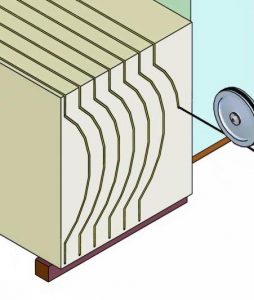

The process can be set to vertical cuttings, to vertical profile, by the use of monowire or twin wire or even set the support wheels to work on horizontal process allow long stones cutting, by this is the only option to provide longe lengths.

Based on robustness this equipment are able to cut the must hard granites in the world. With experience and tested components over more than 50,000 working hours.

It has a digital programmer that allows you to view various menus from the introduction of the cut dimensions to the appropriate drawing of the profile.

It provides an industrial console to enter the various cutting dimensions and allows controlling the cutting speed by checking the wire tension. Also allows the return of the cut at maximum speed. There are various types of bench for the best working situation.

Technical Features

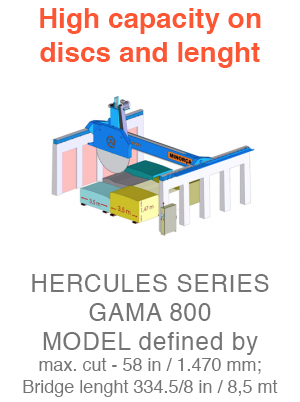

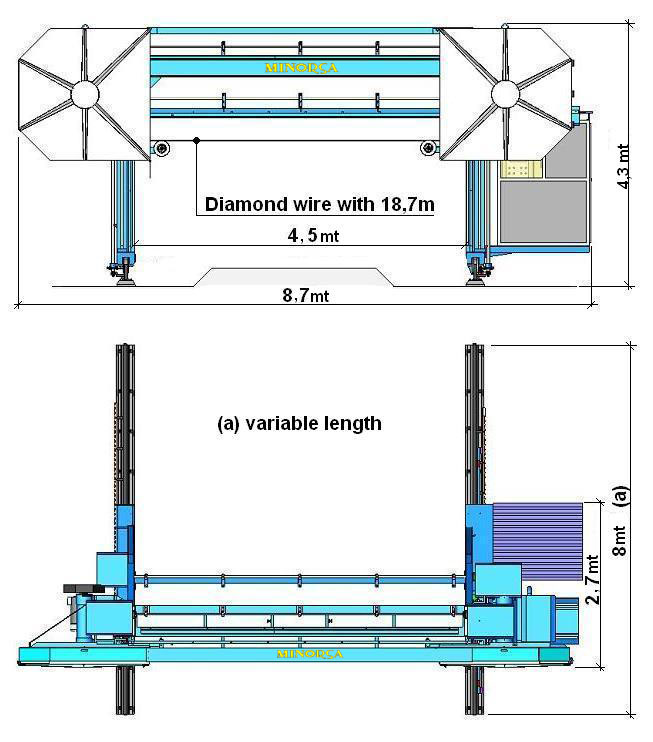

MULTI-MATERIAL WORK WITH LONG LENGTH ABILITY

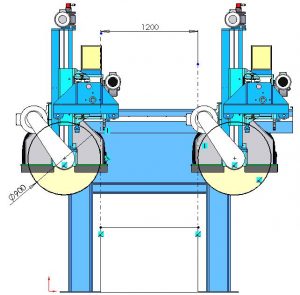

✓ Wheel diameter – std = 78,1/2 inch (in) / 2 meters (mt)

optional = 90,1/2 in / 2,3 mt or 98,1/2 in / 2,5 mt

✓ Max. wheel height – 78,1/2 in / 2 mt = 78,1/4 in / 1,99 mt

90,1/2 in / 2,3 mt = 90 in / 2,29 mt (vertical process)

✓ Standard cutting capacity between wheels – 145 in / 3,7 mt

✓ Traction engine power – 15 Kw (20 Hp) / 22 kW (30 Hp)

✓ Approximate minimum weight – 16,700 lbs / 7,600 Kilos (Kg)

✓ Required max. height – 173,1/2 in / 4,4 mt + rising wheels

✓ Maximum distance reachable guide wheel – 31,1/2 in / 80 cm

✓ Maximum travel speed cut – 70,1/2 in/hour / 1,8 mt/hour

✓ Maximum ascent rate – 52,1/2 in/minute / 1,34 mt/minute

✓ Peripheral speed for cutting – 787 to 1,500 in/second

20 to 38 (or 38 to 50) mt/second

✓ Hydraulic pressure exerted on the wire – 24 to 45 bar

(adjustable and fixed on 1 value)

✓ Permissible wire length – 709 to 736 in / 18 to 18.7 mt

✓ Displacement rails – 216,1/2 in / 5,6 to 78,1/2 in / 20 mt

236 in / 6 mt ; 334,1/2 in / 8,5 mt ; 393,1/2 in / 10 mt

Working Types

|

|

|

|---|---|---|

| Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting |

Profile Wire Saw With the use of multi axis work can shape the material by cable work |

Wire Saw cutting process With one or multiple cables will execute the slab cutting process, the must high height or length saw process |

Multiple Configurations Over Monoframe Wire Saw

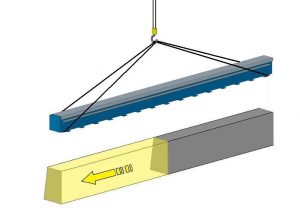

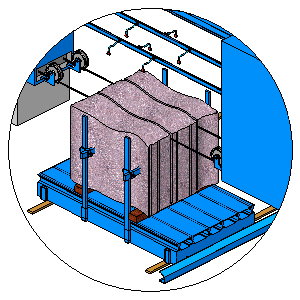

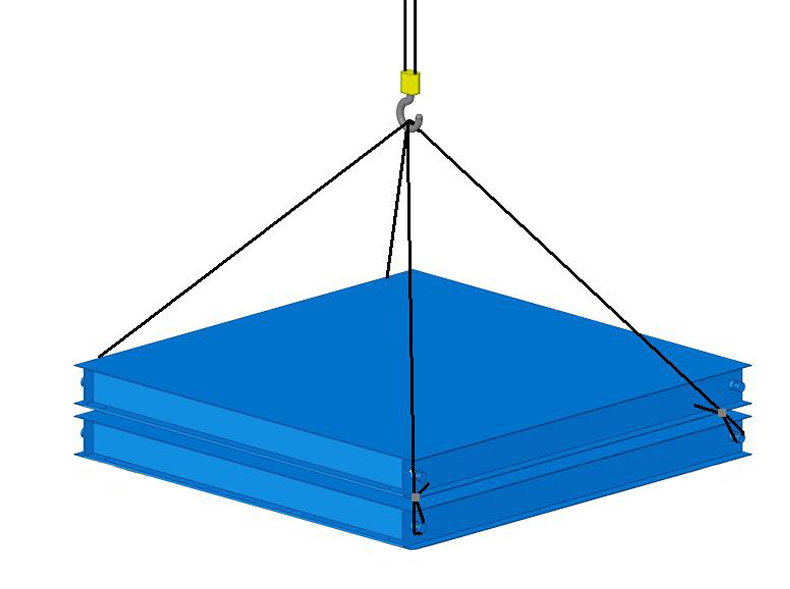

High Capacity With Blocks Over Beams

Will provide fast exchange or let some blocks into future cuts, indicated to charge with front fork loader

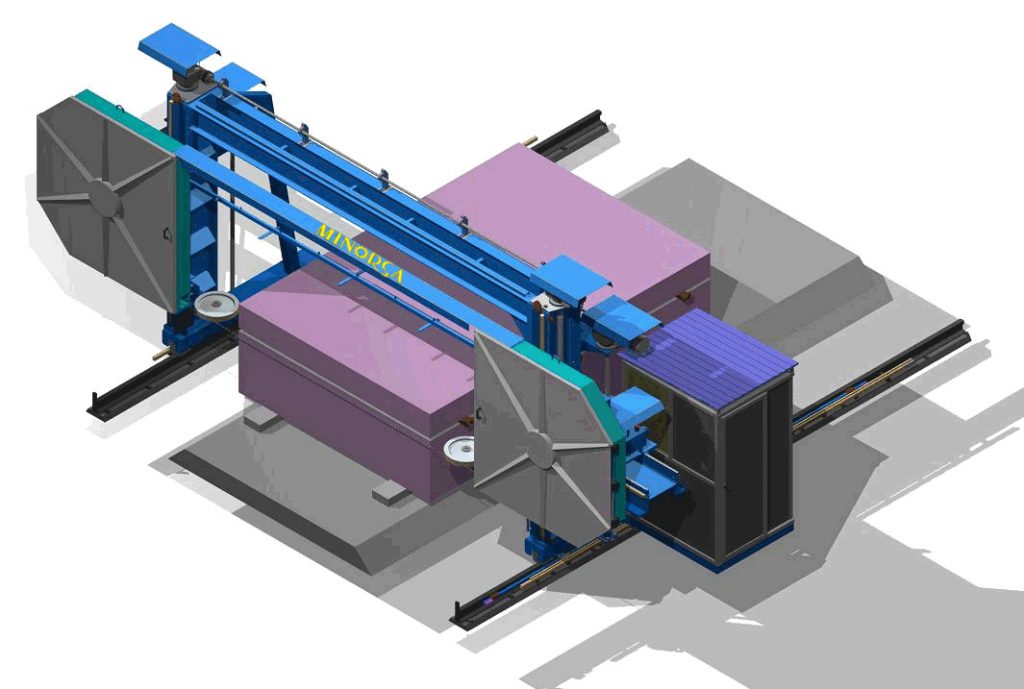

Over Long Rails The Horizontal Saw Produce Better Cutting Quality

Assemble lateral cable support wheels can displace the total equipment on lateral over rail and provide an cut with maximum capacity, better quality and maximum work dimensions

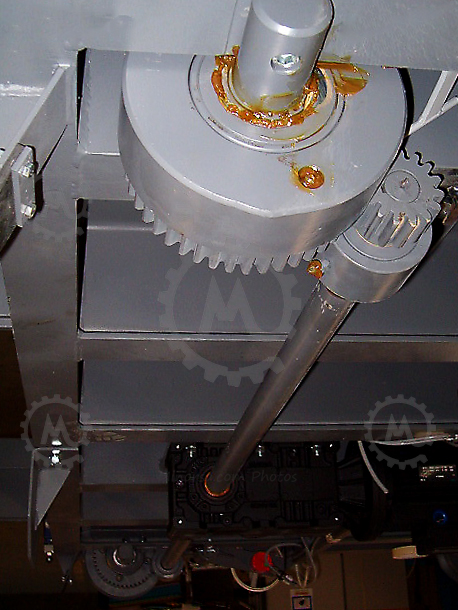

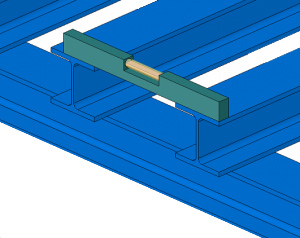

Over Same Lateral Pillars is Assemble Two Wheels Set

With the use of une shaft inside of an pipe shaft we can transmit the power into both wheels, the distance can be changed between wires, the tension is made on individual process.

With an Proper Bench Provides Charging Capacities

can assemble on an Wire Saw with monoframe Fixed multiple benchs, that allow the rotation of the material, the charge bellow an portico crain, or just because of the occupied space.

Over an Ring Frame Provide High Thickness With Several Wires At Same Time

Our development inside over high thickness slab production

Can Set the Displacement on Lateral’s Until 787.1/2 in / 20 meters

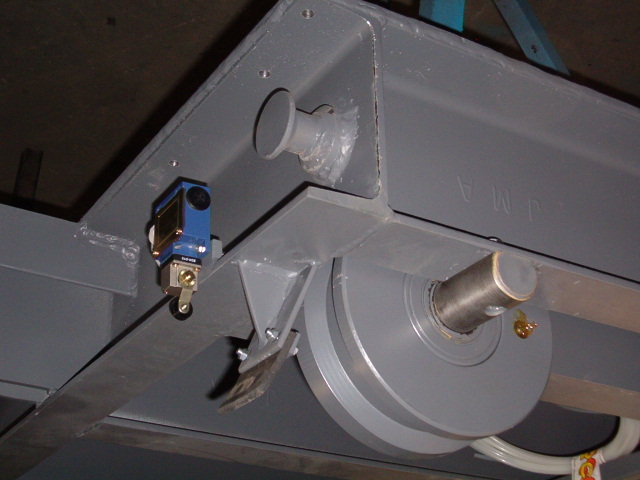

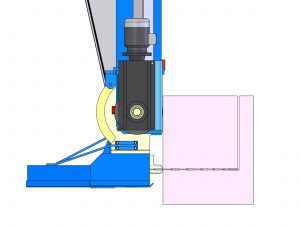

Side pillars are a component of extremely important equipment. An anti-resonance system was developed in these. As a way of eliminating micro vibrations caused by tools, they release a chatter that alters precision parameters as well as measuring the incidence of small marks on the material. On side of the electrical panel we put a constant coverage monitoring in linear bearing, which applies on a support surface. This is a large size to receive the load caused by cutting effort. The linear bearing can move in full oil bath, without twisting maintain a constant alignment of the bridge for displacing the cutting head.

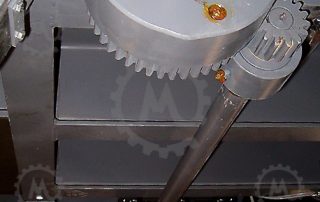

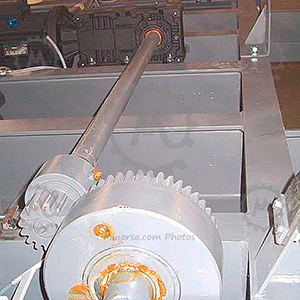

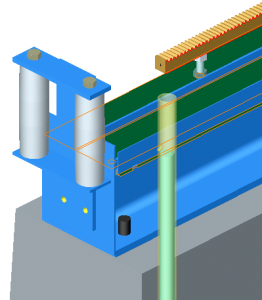

Assembled rack on both sides with adjustment

The weight of the rails is always the same regardless of bridge stress positioning, traction and alignment. With an oversized construction, we guarantee perfection on the side rails as well as the inner rails. All adjustable in positioning and fixed by iron bolts, the rails move from bottom to top of the gear, machining at once, ensuring perfect alignment of parts for a long time.

Stainless iron guards assemble

Can mount guards on stainless iron or bellows. We mount the bellows on small displacements, and the stainless 1/8 in. / 3 mm. in all others dimensions. On the top we screwed it and the displacement carriage has a bearing support to allow perfect movement on long distances.

Both pictures show the both sides. The interior has separate boxes to avoid the mud, for oil bath work, the side box has different dimensions on each side, on the mud side there is a system for removing resonance and on the other side the linear bearing guide for providing constant parallelism.

On Block Wire Saw to outside or to quarries we adopt the use of Train Rail, machined on measure side to improve the verticality of saw process.

All equipments are total assembled on factory and subject into an exhausting test control

Small parameters are adjusted in the assembly process, parts are deposited in a transport box, plastics to cover the motors.

Machined surfaces on every alignment parts and support

Assembled an train rail to guide the monoframe over, that allow the work outside, avoid any stone brake an light rail. There are an slab to removes the projected mud.

Standard manufacture and procedures

Hercules Series pieces are designed in series to improve their quality as a product, part and component that will integrate the equipment and thus build reliably. If you think in profit and production 24/7 at full time, assemble by working process to ensure the well final product, and check every part after placing it on several components to send to final address.

Best Optimize on Working Table

For each type of work, we have a more suitable bench solution

Continuous rotation bench allowing 32 tons.

Ideal for transferring materials out of the machine without interruptions. The rotation is electric and works on a fabricated ring, on the outside or the base of the must. he ring is on conical shape to provide of 98,1/2in / 2,5mt and can assemble side arms to provide 118 in / 3m, the working height start on 29,1/2in / 75cm with the train rail on concrete to elevate from water on floor.

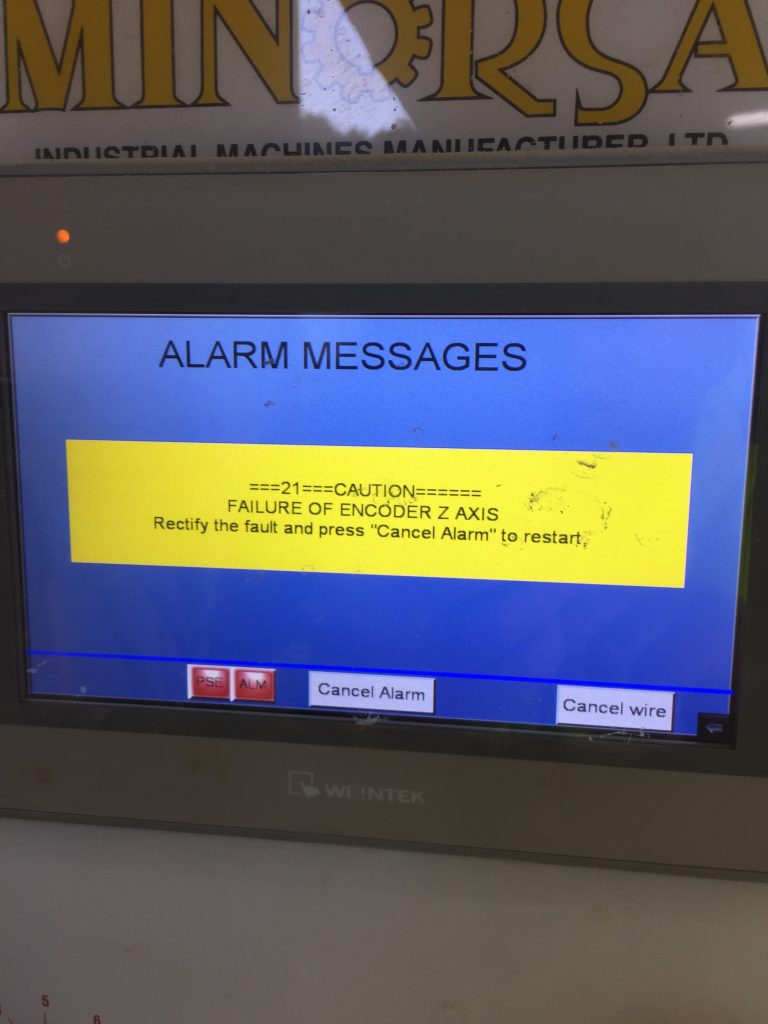

Measure system on moving benchs with encoder coupled with an wheel with rubber pressed by an aligned spring to work directly over the rail.

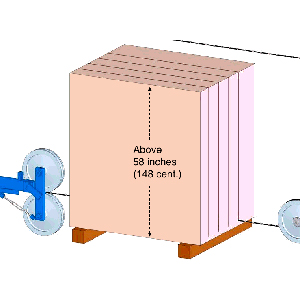

Moving bench allowing 32 tons

Often used to transfer block from outside into the machine, it is also a solution to be used on the second bench with the exchange of workspace on another table to provide multi-head work used with metering system on stationary saw machines. The surface has 98,1/2 in / 2,5 mt by 59in / 1,5m and can assemble side arms to provide 78,1/ 2 in / 2 mt, the working height start on 19,1/2in / 50cm with the train rail on concrete to elevate from water on floor.

It has an easy wheel access through a bolted axle, a machined button surface to receive gearbox, and also axle on the wheels. It works with carriage on a pair of sprockets. This model started shipping in 1988 and it was designed to be simple to handle and to able to incorporate the various saw models. It has a solid structure, built in several sleepers to ensure the installation of weights in all positions.

Fixed and square table with top rotation.

Ideal for working with large quantities of small strips, the square top allows you to position material and process longer in automatic execution. The maximum upper square is 137,1/2 in / 3,5 mt with a rotation base of 78,1/2in / 2m where a crown bearing is mounted in the center to provide rotation due to the size and weight of the upper bench, the process is not fast but accurate, The height starts at 19.1 / 2in / 50cm, and the entire seat is fixed to the floor by simply rotating the top table and not moving sideways.

Fast and Easy

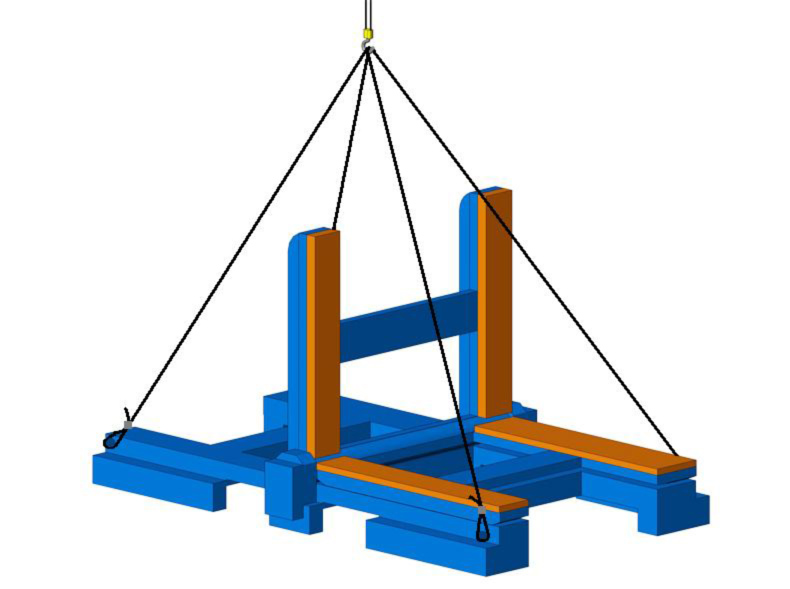

Quarry Assemble

Put the rails on level, measure, fix it and with an fork loader just put the monoframe above.

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

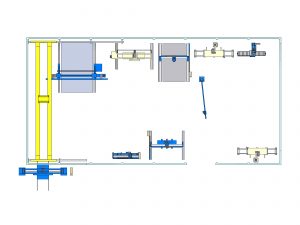

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Machine Dimensions Overall Occupied Space

Accommodate Slipping

The Standard Production Allows Increase Several Components in All Gammas

Final Work of granite cornice

An internal drawing program designed to be operated with great simplicity and that ensures most of the works, leaving the user to parameterize several variables in order to ensure the final quality and increase productivity. It’s possible make fast thinning as time optimizer followed by thinning to the desired height and with the final cleaning cut adjustment by close passages to the final product, ready to receive the surface finish.

The program claim is allowed operator without specific expertise on cad cam operate the equipment, leaving the option of more elaborate programs to be received by wi-fi or pen drive and operated by cycles in automatic execution.

Block Tilt Bench

Special order accessories, system in U shape to receive multi small stones.

Industrial panel to allow work in industrial environment.

Can improve the cutting capacity as 89 in / 2,26 mt or 98 in / 2,49 mt ; also allow the work with less diameter wheels as 63 in / 1,6 mt help on places with less height; must remember the high diameter let the wire turn with less curve providing more working hours and help the cable heat.