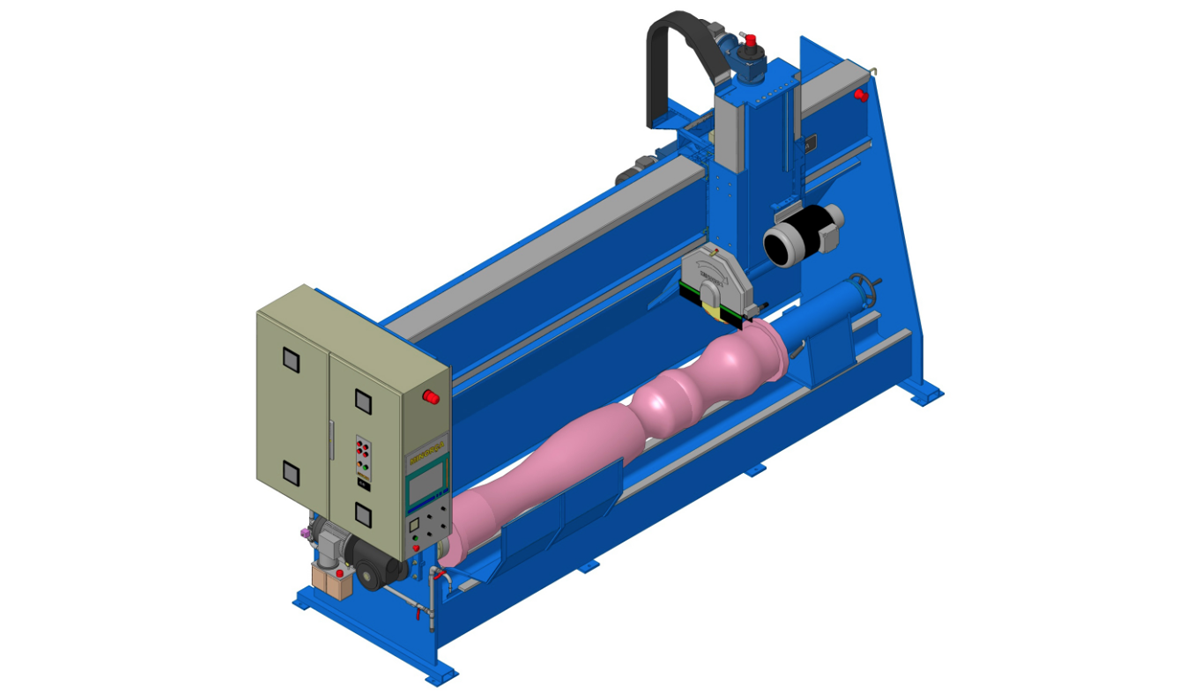

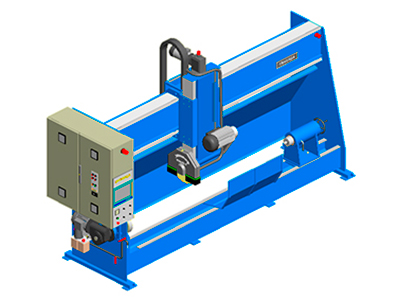

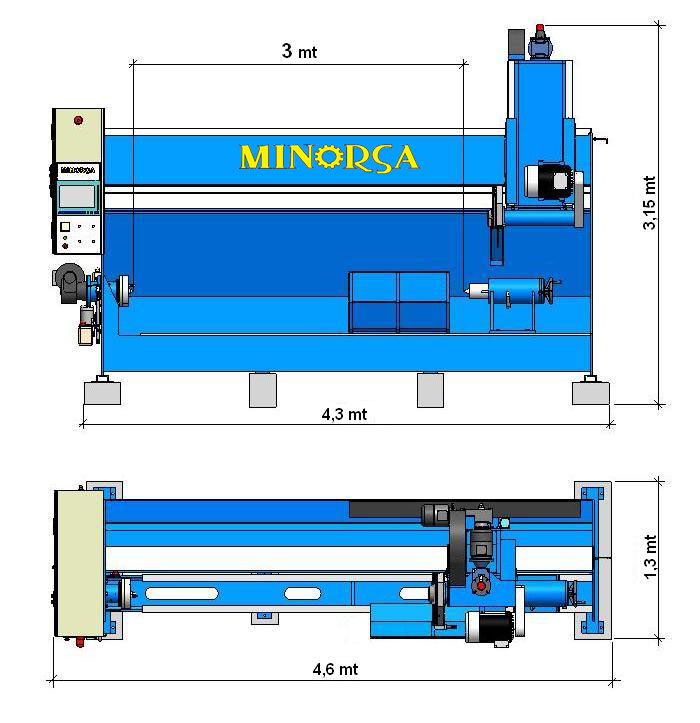

Monoframe Lathe With Draw System

About

Developed for fully automatic operation, which is programmed on the equipment itself by drawing straight line and arc segments. It also allows controlling the cut and rectifying speeds, it will leaving the piece totally clean and ready to be polished.

The displacement of the axles is done with electrical engines through linear guides placed on rectified beds. Since produce balustrade or round columns, the system allows regulate velocity, control the drop into the material, adjust the end of cut leaving the required space to move on both axis providing an cleaning and round surface.

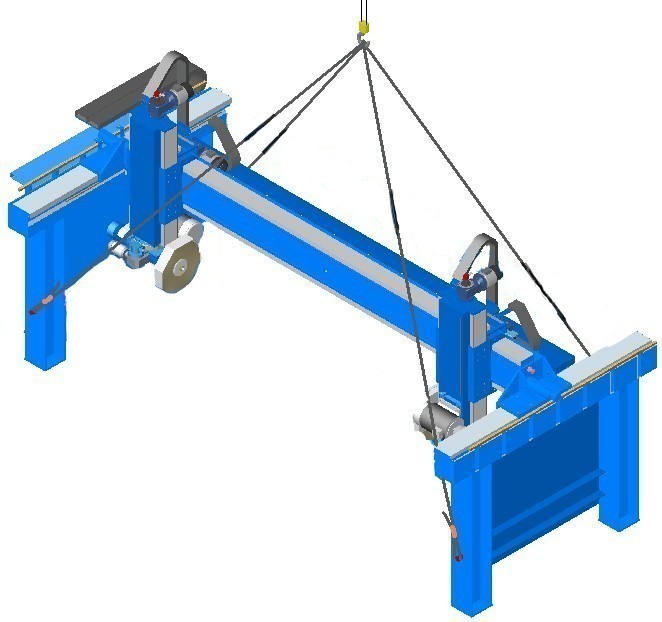

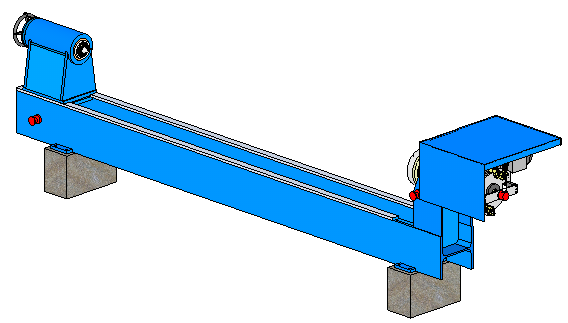

Supplied in monoblock frame will be easy the installation, also the transference on site.

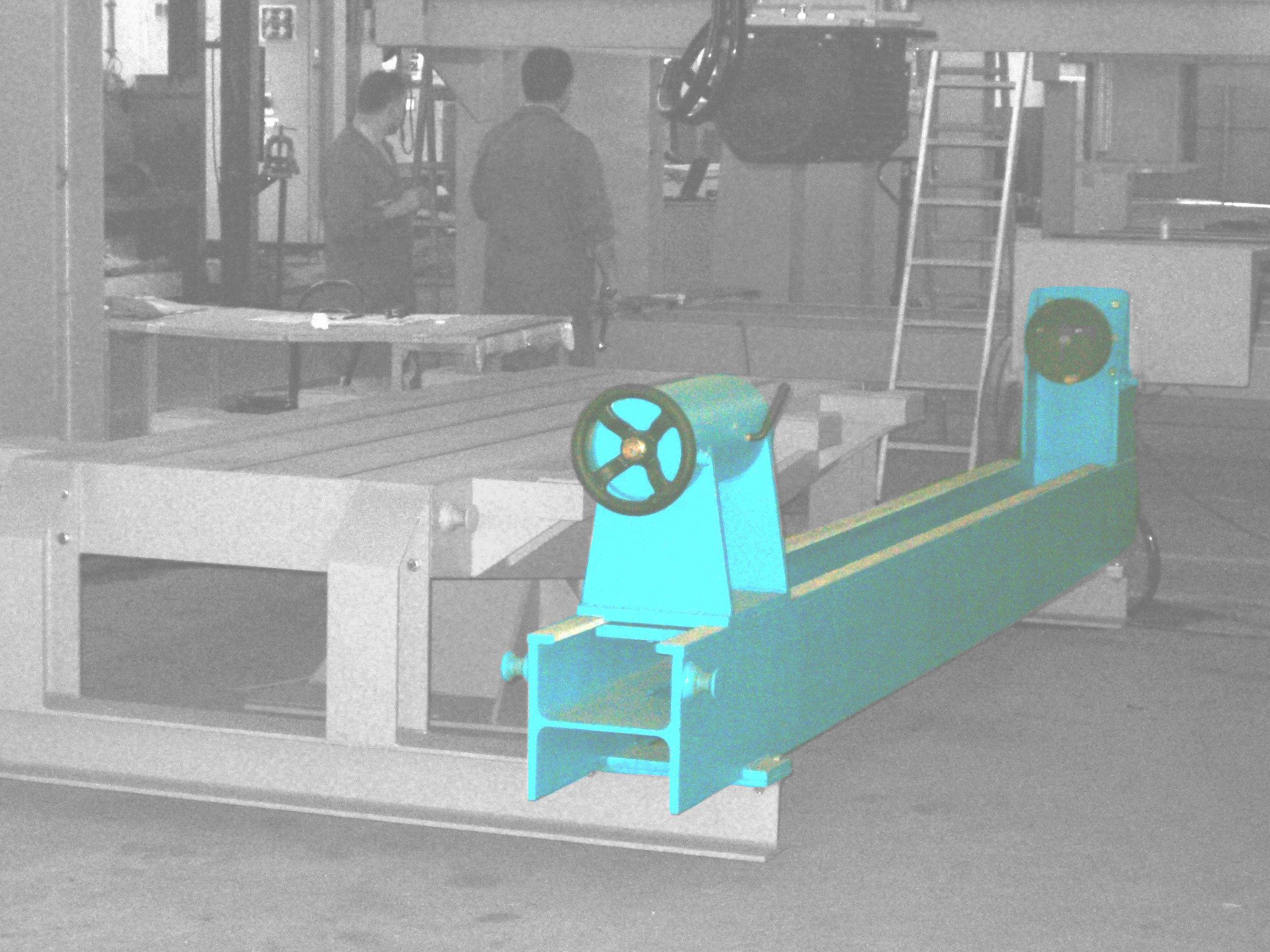

We produce automatic lathes since 1982 with this monoframe concept on 1984.

Technical Features

CUTTING AND GRINDING READY TO POLISH, DRAWING PROGRAM

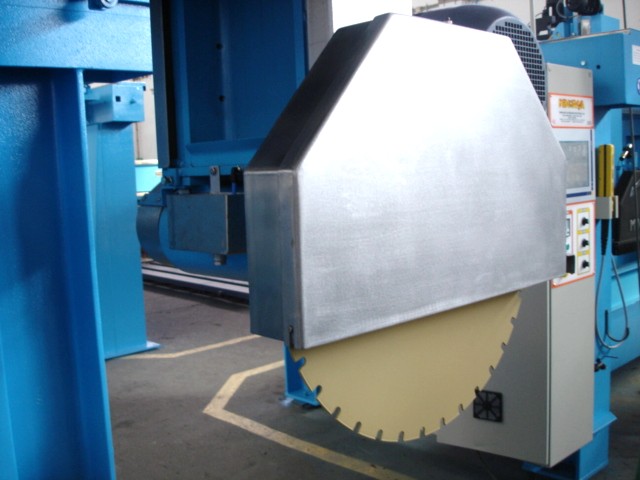

✓ Diameter of disc admitted – 35 cm to 17,1/2 in / 45 cm (for+ optional)

✓ Maximum cutting height – aprox. 6 in / 155 mm (Falange support 140mm)

✓ Turning capacity – 118 in / 3 mt / 19,1/2 in / 0,5 mtØ beginning with the 710mm

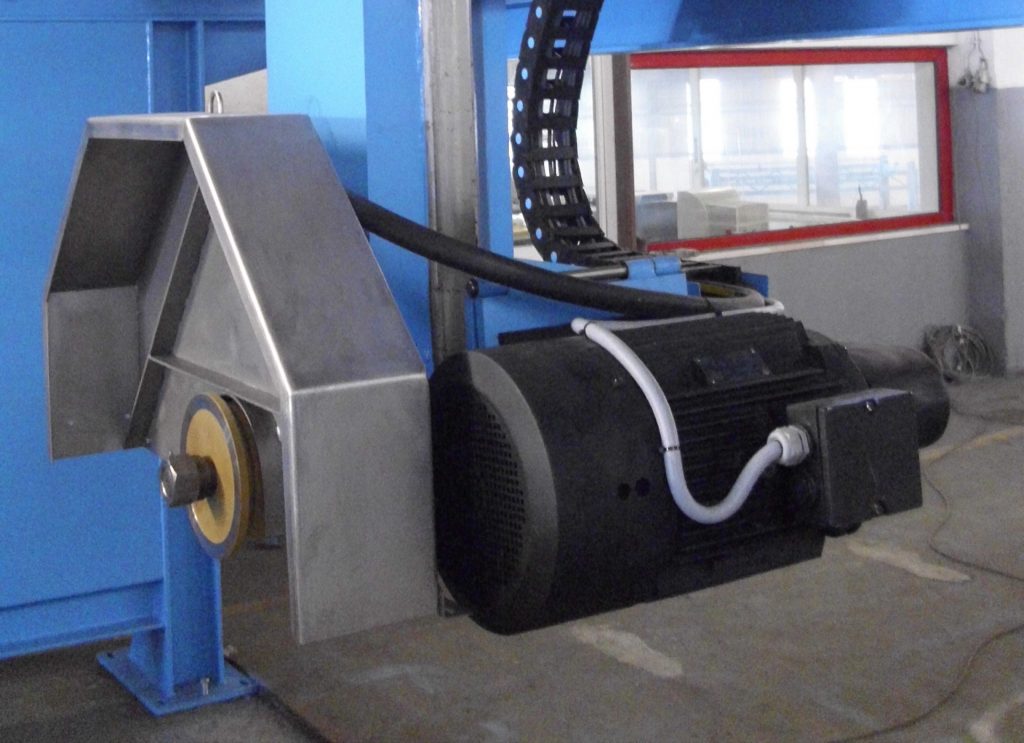

✓ Cutting motor power – 7,5 kw (10hp)

✓ Approximate minimum weight – 8,200 lbs / 3,730 Kg

✓ Maximum height required – 130 in / 3,3 mt

✓ Bridge length (for+ optional) – 157,1/2 in / 4 mt

✓ Maximum speed head displacement – 4 mt/minute

✓ Minimum peripheral speed for cutting – 26 or 47 mt/second

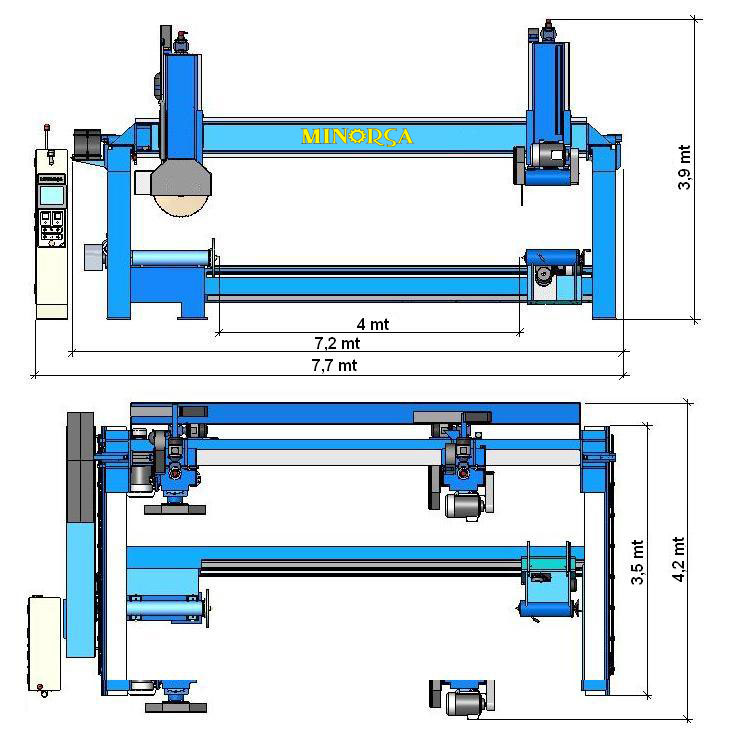

Fixed Bridge Saw over Lathe Spindle Monoframe

Two gammas allowing full cutting capacities with the use of minimum workable length 118 in / 3 mt and maximum on special size of 394 inch / 10 meter, providing a top range over high thickness.

The base equipment is defined to have an high range over daily work

(Can define over the maximum length the work type as with twin ram, the travel)

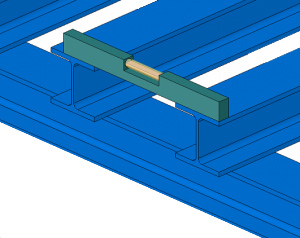

Pulleys Flange over base frame

6 in / 15,5 cm disc 17,1/2 in / 45 cm

Over Maximum Fastness

9,5/16 in / 23,7 cm disc 28.1/2 in / 72,5 cm

16,5/8 in / 42 cm disc 43 in / 1,1 mt

19,11/16 in / 50 cm disc 51 in / 1,3 mt

23,5/8 in / 60 cm disc 63 in / 1,6 mt

(With the need to perform channels, boxes, spirals, milling bases must adopt an moving bridge)

Working Types

|

||

|---|---|---|

| Balustrade And Columns In Round Shape

Can do with proper cad program worked stones in several materials and also forms, like final quality, that one can be perfect, ready to polish |

Specific Frame Adjusted to Increase Proper Work

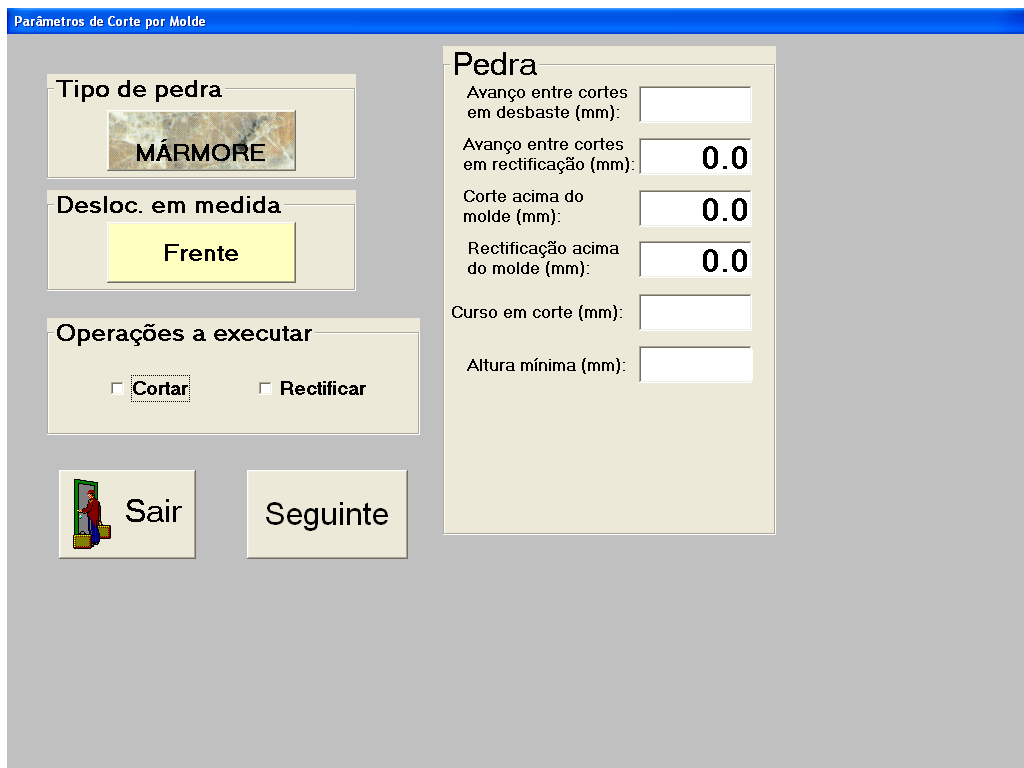

A Solid Program with Single-Service and Pre-Forms Concept

With the internal use of cad system, machines can cut surfaces without external resources.

Defined the spacing between cuts

The distance limits, as the distance of the vertical cut in a protrusion (avoiding premature material removal) and the distance between cuts (as a way to speed up the process or improve the preparation for the final cleaning), are defined on the base drawing. This is something that can only be obtained in specific programs for the execution of stonework.

Can draw lines and arcs also ellipses

It’s possible make parameter adjustments, copy parts to add, delete zones, modify only a area, mirror, and work on a square grid.

Set all auto mode

Several functions are available to define how you want to do the job, as the cut distance above the knee or the cleaning distance above the drawing. It’s possible select cuts in double way, adjusting the performance to the material hardness. You can return a work that has been interrupted by a power failure.

Pre-view of cutting operation

With this view where a faster roughing operation can be performed, it’s possible make the cut simulation, and check where it will concern on the final, and can change the cut location to leave no defect in the finishing zone. It makes zoom, view the work in full view and shows the final finishing line.

Execution screen view on granite column

There is a simulator to view the work final aspect, and is very useful to show the final product to the client. The execution of the drawing can be performed in any position, with the simple the simple definition of the cutoff point and the operation can be multiplied. Also, the linear offset of cut is defined. All in order to maximize the available cutting area.

Final Work of granite balustrade

An internal drawing program designed to be operated with great simplicity and that ensures most of the works, leaving the user to parameterize several variables in order to ensure the final quality and increase productivity. It’s possible make fast thinning as time optimizer followed by thinning to the desired height and with the final cleaning cut adjustment by close passages to the final product, ready to receive the surface finish.

The program claim is allowed operator without specific expertise on cad cam operate the equipment, leaving the option of more elaborate programs to be received by wi-fi or pen drive and operated by cycles in automatic execution.

Several Potential Allowing Extreme Final Works

With the constant intention of equipment to make the most of it, its development has the polyvalence of can be adapted with the factory needs. To fit in with the constant evolution of the market we have developed several separate accessories that can adapted, (depending of the frame base) in order to keep the equipment at its maximum performance. It is designed for a for full non-stop operation and maximum utilization of both installed capacity and working time. Therefore, whenever you are on hold you can do lengthy or for stock.

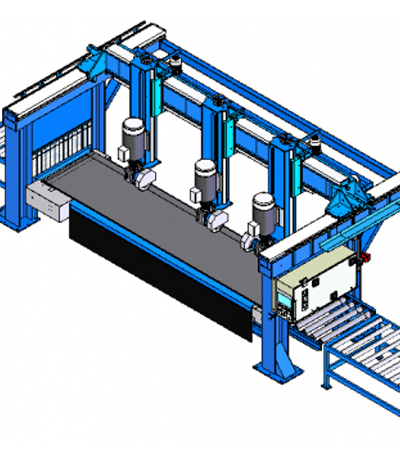

Exist the option of add more length on lateral travel rails, that will allow an rear bench, roller table, lathe assemble to support material to be cut in several stages, because the equipment has the ability to pause this operation for direct operation and operator intervention will be possible use the time between main work. Through multi-heads you can consider multi-operations, the same surface polishing, rear bench use to edge polishing or production of colunes.

Must consider the Hi-Tech Combi Bridge Saw with continuous rubber rug model.

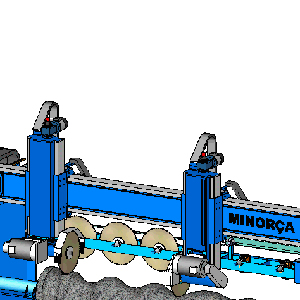

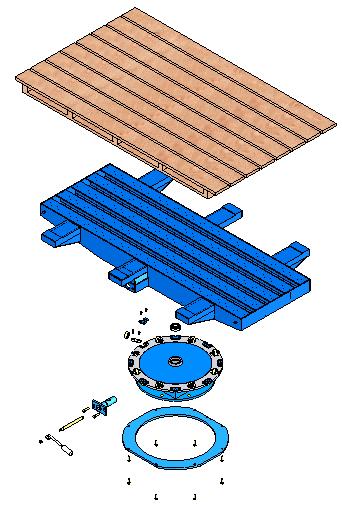

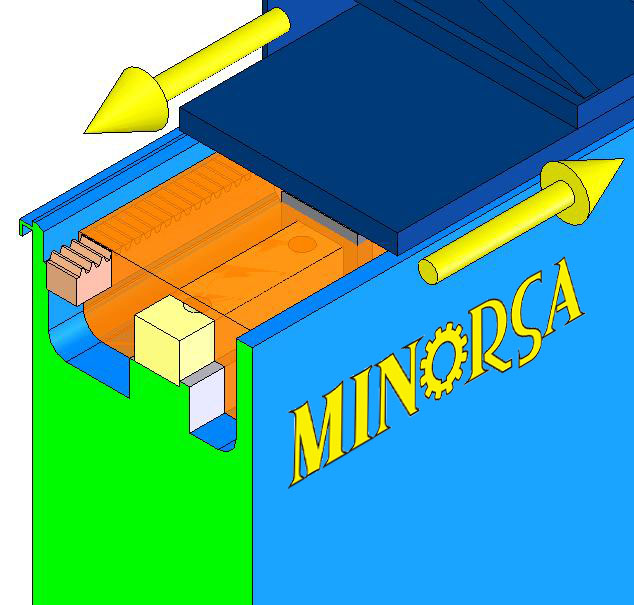

Rotating axis (lathe work with blocking system)

Can produce rounds, squares and other shapes. The regular dimensions are 118 in / 3 mt long with ability to work 19,1/2 in / 50 cm from a square shape (aprox.70 cm between corners), the best is use all capacity on travel RAM assemble an rear optimization or divide the rear space by an bench plus the lathe. We have available the lathe body until 394 in / 10 mt between supports on granite columns with two cutting heads, since 1982. To use on gamma 800 Hercules Series.

In complex jobs, you can apply a double branch to duplicate the process. The finishing work is completely clean and ready for surface treatment.

With a breaker system and an angle measuring system that can block all possibilities of allowing the saw to work, the entire body of the mechanism is removable and can be mounted on a concrete base or on a suitable worktable. The saw can work this way on many sides.

The switchboard can be mounted under the mechanism and can be autonomously transformed to perform other tasks manually or to insert it into multiple machines.

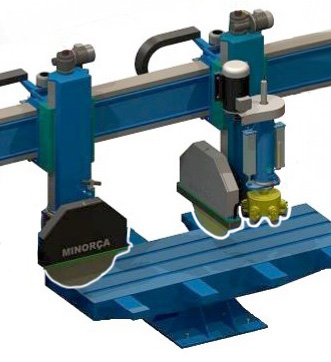

Multi service & multihead

The developed ram allows assemble multiple heads, that don’t need to work at same time but are assembled to complement the process. One will be the main head and the other can be ready to work as desired by changing the positioning. The main disk is lock on the top, but when down it will work on regular way. It can be for sawing, high-speed drilling, polishing, vacuum or clamp lift or to adjust another cutting body with wire saw or chain saw or moving bridge to move the stones. Depending the intent, you can change heads on moving bridge, you can work with multiple accessories on the bridge rail and can support multiple bridge systems to compliment itself. There are many options focused on increasing production, which can likewise work with multiple systems, offering multiple tasks, complementing the process or multiplying production.

The advantages of this tool include multiple identical heads on same the bridge, different heads on bridge, dual heads on one head, multiple head on multiple bridges and different tasks with several bridges.

For Details check information on Option Dedicated to Multi-Services on machines main menu.

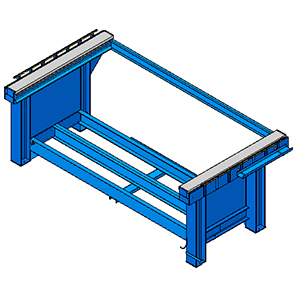

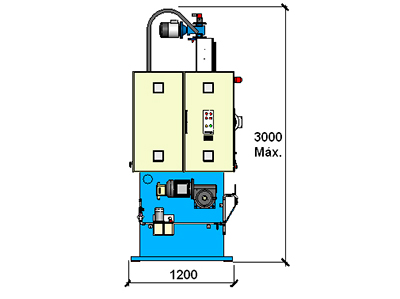

Can Assemble the Bridge Saw Over Metallic Structure

A good equipment support is primordial for a maximum yield on cutting process effort. We have two metal columns models, that can be mounted, depending of the bridge width, the ram height and the available power. Above structural value is suggested that the mounted be made on concrete. Since 1985 we have been assembling with 30 horsepower and 44 amperes effort. After 2002 we started to provide a 236 in / 6m cutting bridge for 55 ampere shear effort or consequent ram movement inversions.

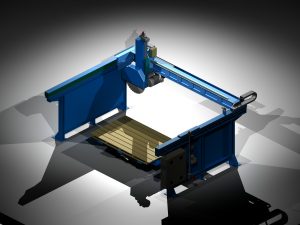

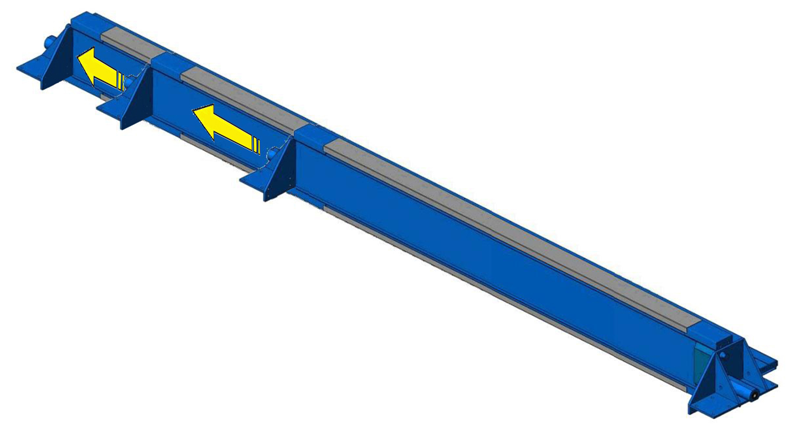

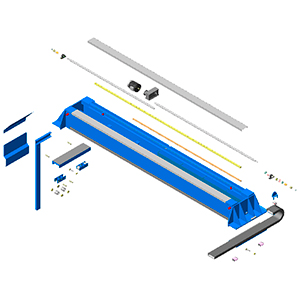

Monobloc Frame

Concept presented with an compact structure as a one-piece mono-block for easy installation and faster on-site equipment exchange, boasts thicker steel legs creates the monobloc, The main board separated from the machine to avoid vibrations and has easy access to programer screen. Maximize the cutting process with a precise and solid cut due to the use of the latest technology. It can be configured with one frame or multiple frames or only the continuation of lateral rails providing more bridge displacement for machines up to 43 inch ( in ) / 1,1 meters ( mt ) of the diameter and bridge length until 236 inch / 6 meters.

The upper surface must be correctly aligned and leave the gaps open to allow mounting and closing after equipment testing.

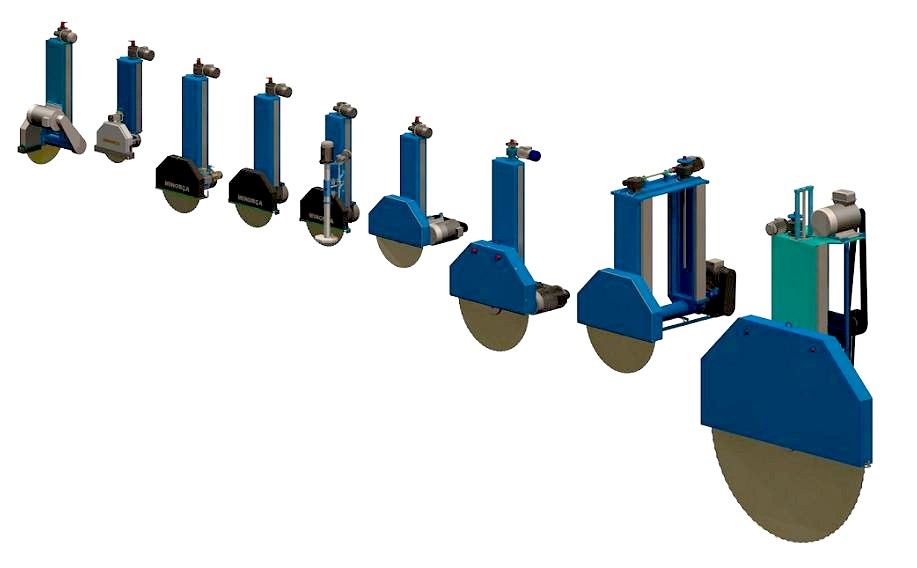

Several Sizes, Same Concept to Accommodate the Multiple Cutting Heads

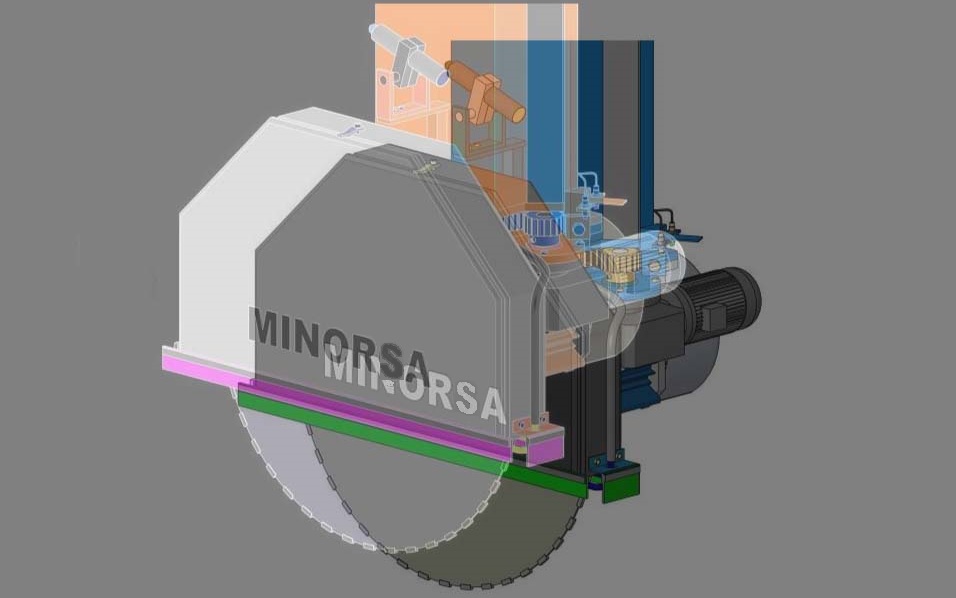

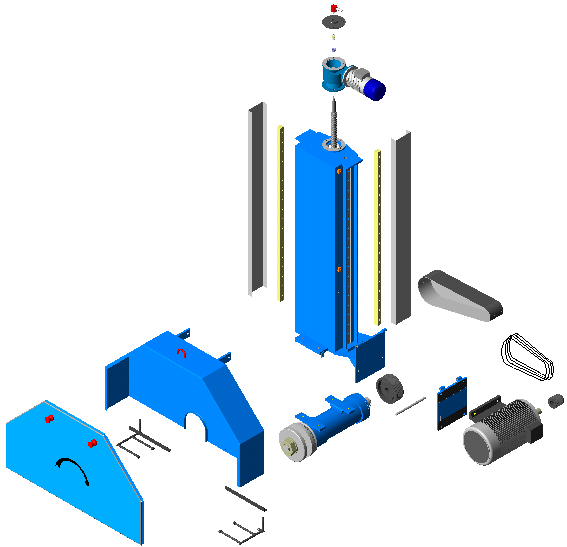

The concept of the Hercules series is to share components and the concept across gammas. With the development of cutting heads since 1985, where we produced the first vertical ram with an adjustable V-system, we have been improving the displacement of cutting cars to this day. Using dual coupling methods, we provide the best level for customer work, with robustness and versatility ram for a fast-displacement car. We have several displacement, robustness and body sizes options (as shown in the initial image) to optimize work, mixed with the head change system, everything can be done and eliminated.

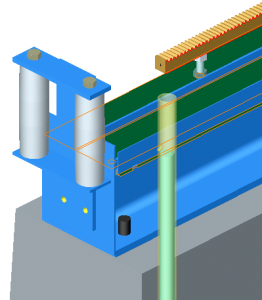

The displacement of RAM is constantly supported on bridge cutting car

Increasing the height in the occupied space can adopt more length, change the way of cutting, more cutting diameter, optimize multiple head in the work area. Vertical linear bearing displacement support is selected in case of positioning speed improvement, or compensator weight need to increase repositioning needs. The guides are protected with mud guards and allow oil lubrication under correct conditions.

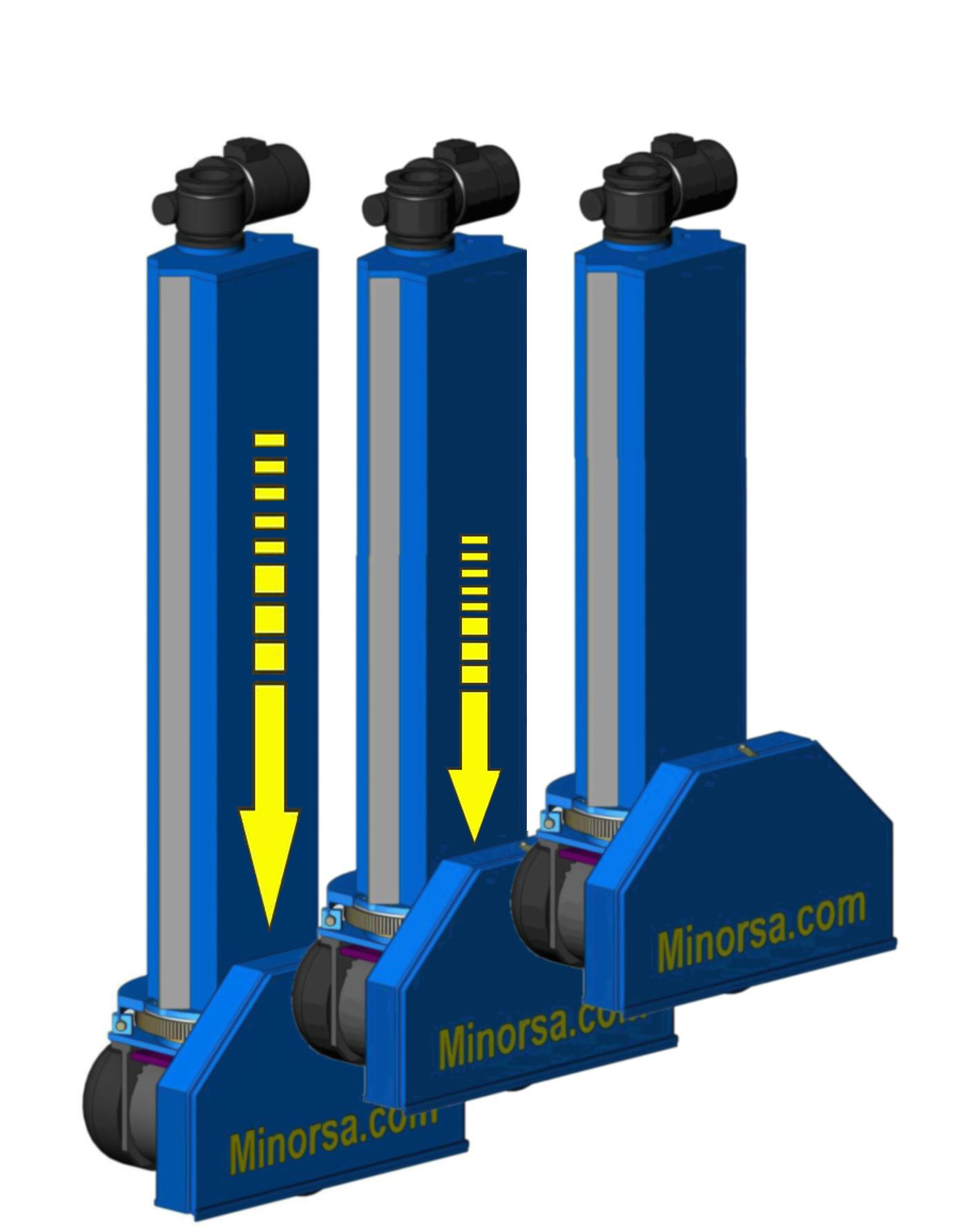

Several displacements on vertical ram

Displacement System Ideal

16 in / 40 cm Linear the base to round shape production with high power

27,1/2 in / 70 cm Linear the option to work over rolling bridge

35,1/2 in / 90 cm Linear the ideal of multi-purpose saw on lathe frame work

Technical Features

WORK type RAM System Ideal

Lateral Shaving Process Linear high power transmission

with specific disc high velocities and travel

Robustness and best optimization

The bridge shift carriage provides a perfect accessory for the vertical work ram.

The robustness of travel RAM is one of the important bases of an perfect finish work.

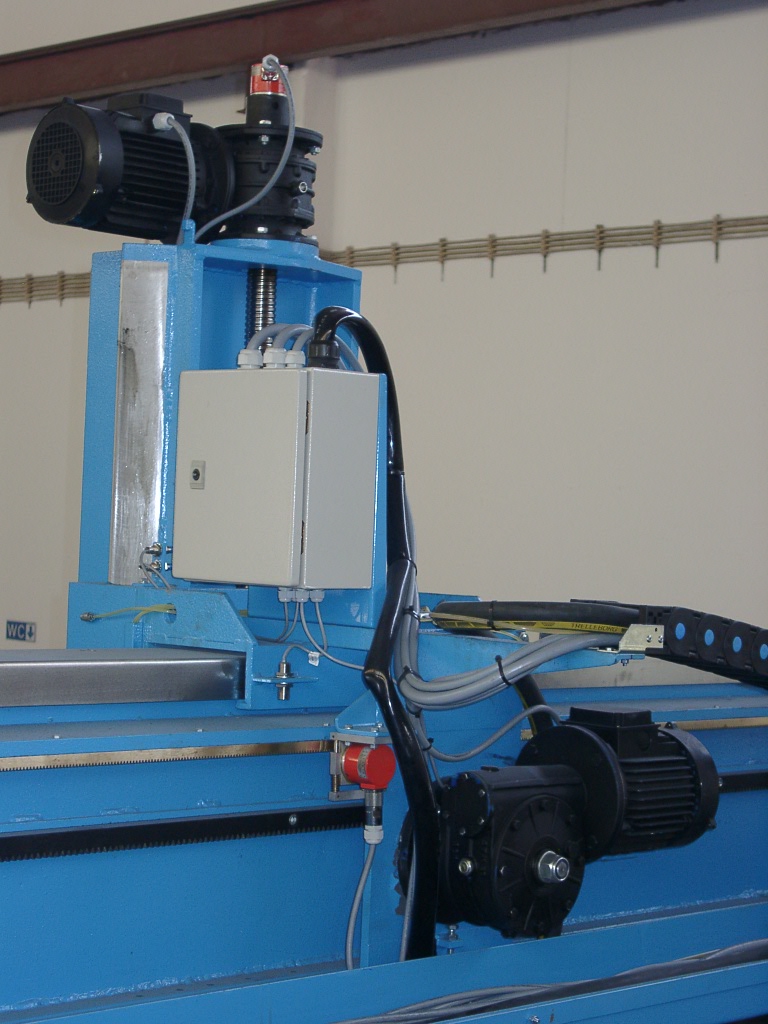

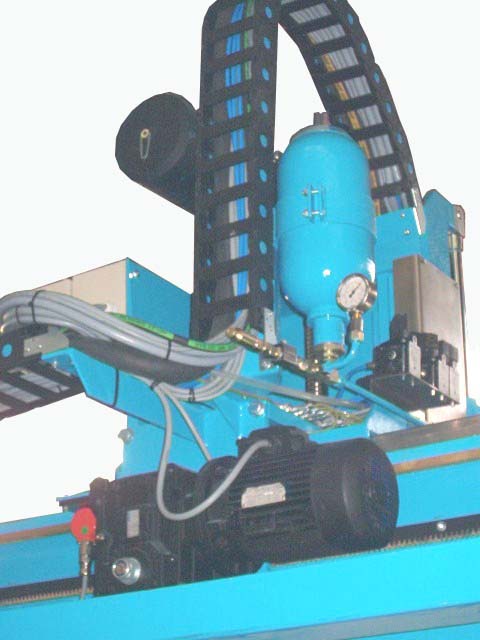

Ram is improved with the best components such as a hydraulic weight compensator and a ball screw. All contact surfaces are machined, and the interior has an industrial shape focused on work performance, not beauty.

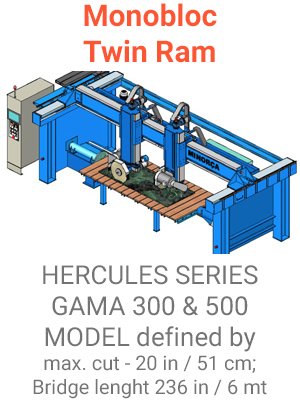

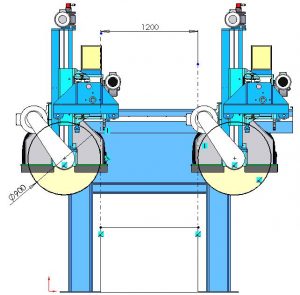

Twin RAM over Monobloc

About

Its ability to turn a piece capacity with its own design programe, means it can do grooves, square pieces, etc.

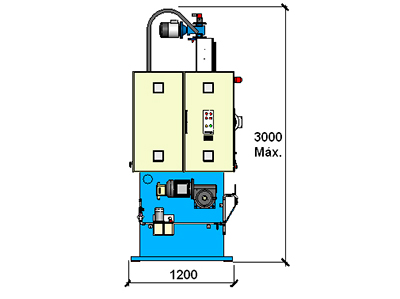

Technical Features

✓ Diameter of the disc permissible – 600mm to 725mm (900mm)

✓ Maximum cutting hight – 235mm (Falange 250mm)

✓ Vertical displacement minimum – Z= 470mm (for more optional)

✓ Cutting capacity – X= 4,000mm (for more optional)

✓ Power of main motor – 15 kw (20hp) / 30 Amp. ; 22kw (30Hp)

✓ Approximate minimum weight – 7,000Kg

✓ Maximum height required for operations – 3,9 meters

✓ Cutting displacement velocity’s – 20 mt/min.

✓ Minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

The Lathe Work Over Mono Frame Receive the Start of Gamma 300 and Bigger Size on 800

Bridge length between lateral frame support Available cutting capacity

157,1/2 inch / 4 meters (with the gamma 300 bridge assemble)

until 394 inch / 10 meters (with the gamma 800 bridge assemble)

Pulleys Flange over base frame

6 in / 15,5 cm disc 17,1/2 in / 45 cm

Over Maximum Fastness

9,5/16 in / 23,7 cm disc 28.1/2 in / 72,5 cm

16,5/8 in / 42 cm disc 43 in / 1,1 mt

19,11/16 in / 50 cm disc 51 in / 1,3 mt

23,5/8 in / 60 cm disc 63 in / 1,6 mt

Bridge manufactured in 2 gammas (sizes) 300 and 800 to use on monobloc concept

Since 1993 we use this displacement system and in 2012 the oil bath capacity.

Serial production of well tested components used for several gamas

Surface treatment on metal components. Steel grit blasting grease removal, and thermally applied zinc coating. This protection is reinforced with an anti-deterioration / aging finish by means of an undercoat, a graphite rubber component layer and high gloss paint top. Hence, we guarantee maximum anti-corrosion protection against its common operating environments.

ALL EQUIPMENT STRUCTURE is designed in forged steel using MIG welding

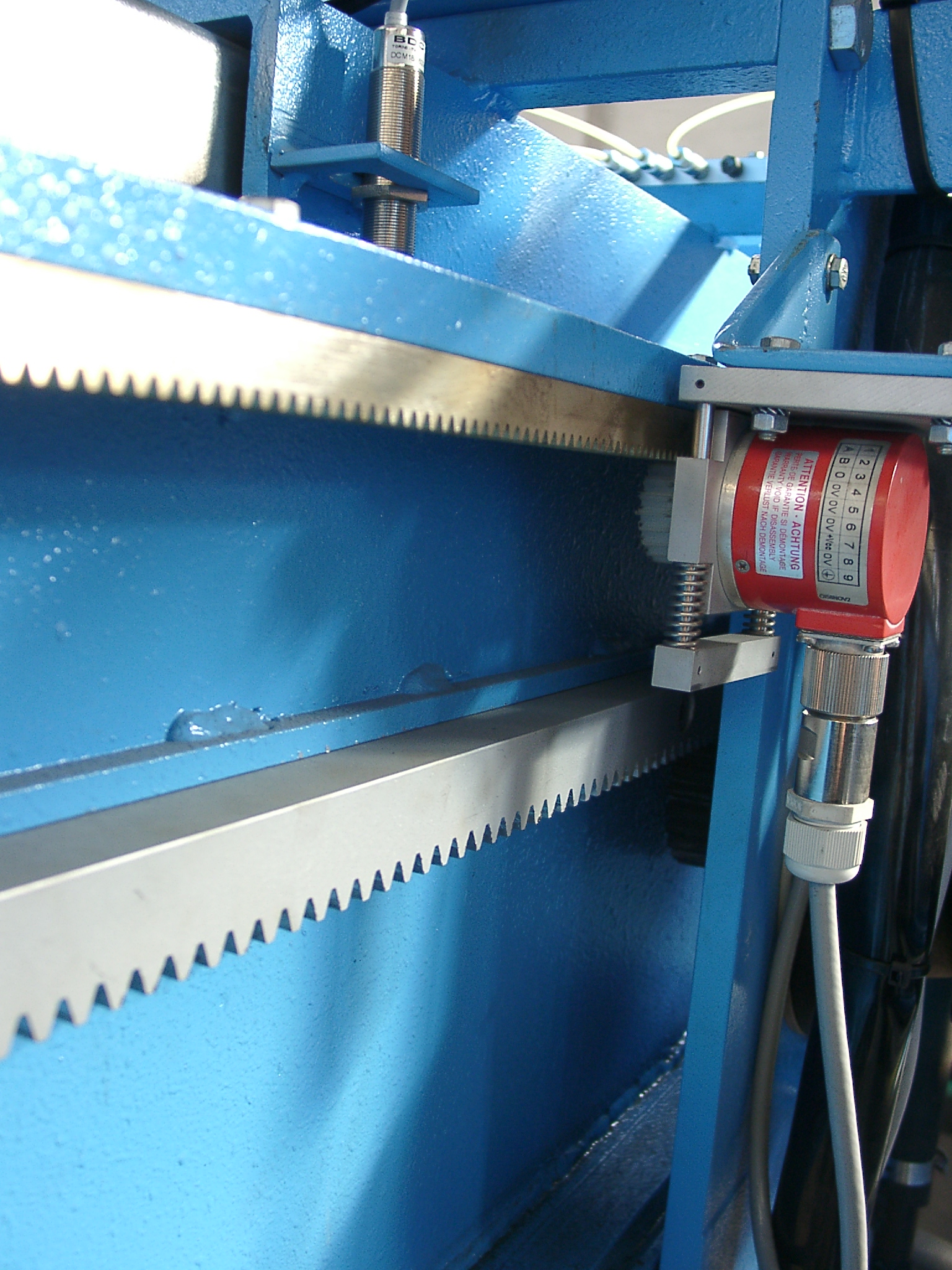

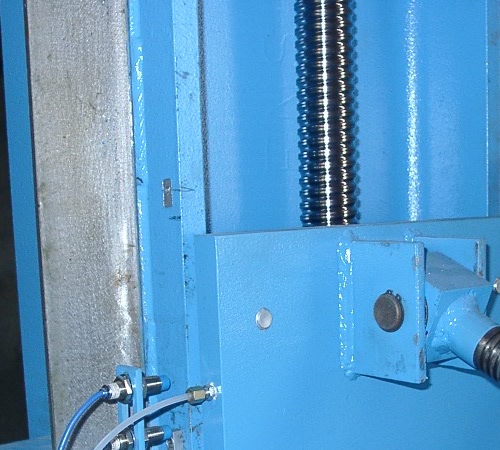

Independent counting system on appropriate measuring rack. It is an equipment with protection guard and stainless-steel bellows, and that support bearings to keep maximum saw pressure on stone.

Fast and Easy

100% monoframe

Level, make the wire connection, water on, take final tests and work specific training, and it’s ready to work 24/7.

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Common Parts

The Hercules series adopts the principle of using common parts by changing their sizes by gammas.

Standard Parts In:

Working tables

The intention is to indicate that the parts and components produced starting in a project were subjected to intensive tests over 50 thousand hours. In the Hercules series they are used according to a manufacturing plan, from individual design of the pieces to their join assembly, with an accessory or component that will be combined with other to get a reliable and cost-effective equipment, easy to operate and maintain, and usable to its full capacity either in production or in its profit.

Cutting heads

All the components are designed to be interchangeable between the Hercules Series. Is this the concept that we intend to present: developed, tested, interchangeable, capable of receiving various upgrades, potential for expansion either in power, and that allowing the accessory exchange.

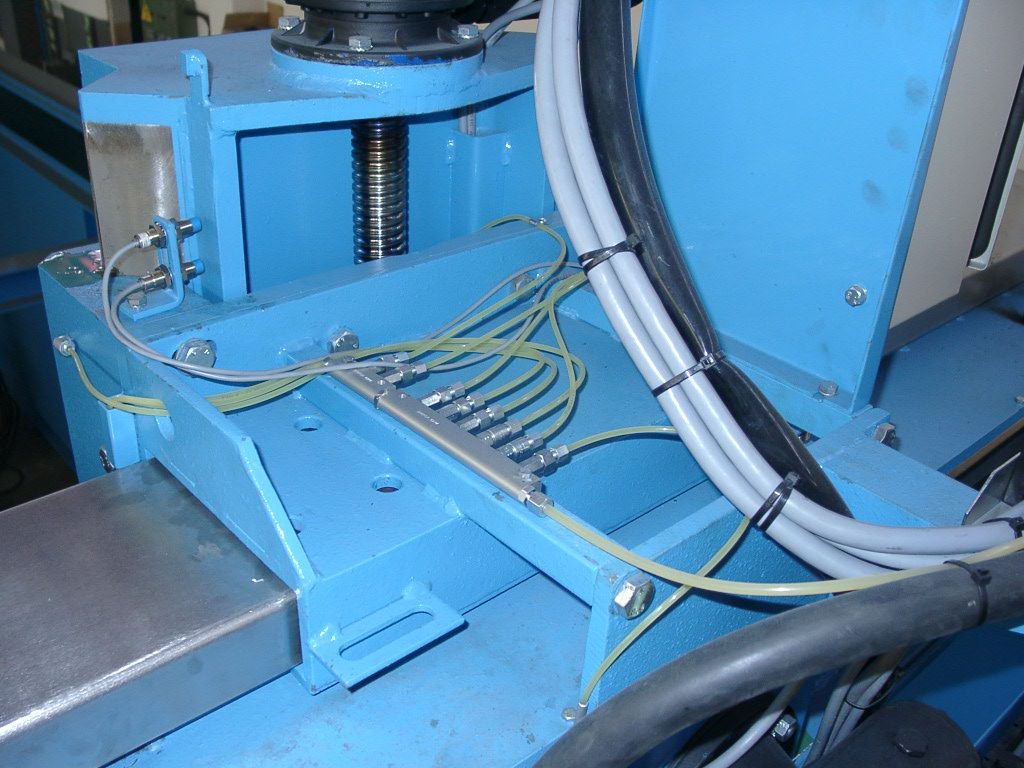

Measure system with independent counting

Based on the concept of making full use of head swapping equipment for multitasking, on the same bridge can be mounted more than one ram model. It is possible with two side supports, with one of two powertrain systems, with two transmission systems or with one of two control systems, but always with the highest quality products.

Independent gear counting system, which increases reading accuracy without the use of transmission elements, allowing positioning of the displacement elements/axes with a maximum error of 2 tenths of a millimeter.

Junction box for shaft cables.

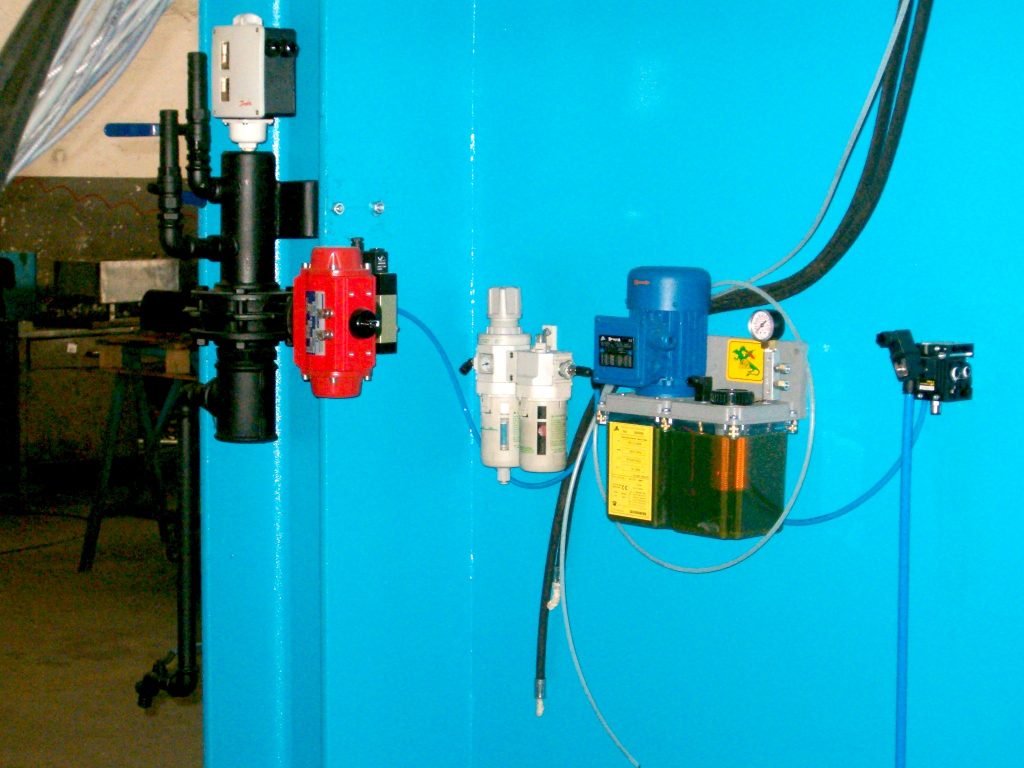

Automatic lubrication on all displacement points: water on/off automatic valve

The auxiliary components are also selected for their good operation and easy maintenance, and the security systems are assembled for easy identification and protection from events.

Power failure recovery (position and status memory) to continue working automatically, saving time and materials to be cut;

Automatic cut-off stop protection, if material gets stuck, slow down or at the end of the program;

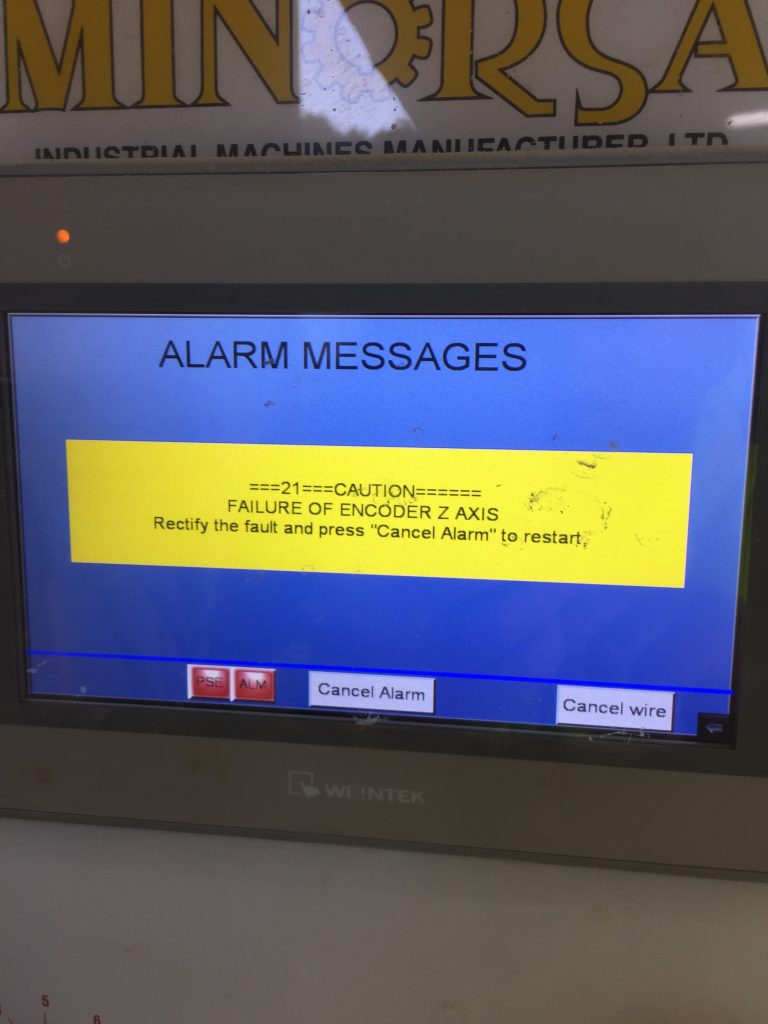

Automatic axle stop/protection in case of mechanical anomalies during operation;

Displacement stops cease working to avoid programming or operation errors;

The equipment stops when opening the electrical panel;

Low voltage manual control switch to protect operator;

Electric protection by using magneto thermal switches (without fuses);

Regulated power supply, protecting low voltage circuits against power surges;

The equipment stops after encoder pulse count failure or contactor obstruction;

Horizontal displacements in oil bath capacity.

Automatic lubrication system with times, which allows keep the equipment lubricated at all its constant movement points, without the need operator interventions with oil pressure switch in case of pressure loss in the circuit.

The displacements can be fully embedded in oil bath, eliminating supervision and increasing time between periodic maintenance. Thus, allow increasing its lifetime.

Laser with continuous focus

Accessories with laser focus, allows the use of laser for better alignment of the initial positioning on the pieces to be cut. One of its features is the individual variable speed transmission, which allows for more precise adjustment of speed and position. This also has water shut-off valves fitted as standard unless otherwise requested.

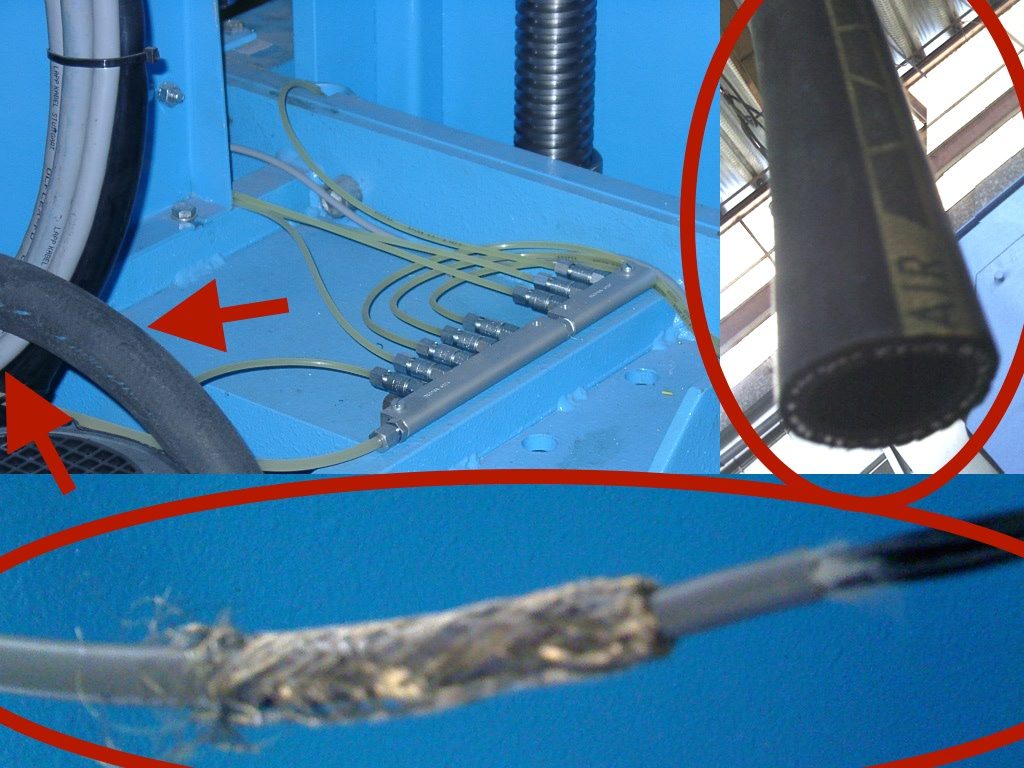

Water pressure system control/protection on cables by cover mesh/pressure water pipes

Special electric cables with mesh sheathed, moved through the cable supporting rails. Measure Encoder component with braided wire mesh cables (counting system) to protect against power surges. The base installation also has inner lined water cables consisting of a mesh reinforced rubber hose inside. Shields and rails for collecting the oil coming from lubrication of material used for cutting. Water pressure switch to control cooling and washing of the saw. (Placed on top of pillar for greater accuracy).

Electric board disconnected of equipment

A pit dimensioned with spaced components and embedded screen. The plate is separated from the machine to avoid vibrations and has easy access, because it will be installed close to the floor. This electrical panel is built in our facilities in compliance with all CE regulations.

Electrical panel ventilation system with temperature control. Software under development to facilitate data entry and reading, based on operator feedback and questions. Mains fault detection system.

Standard components of well reputed brands

Using reputable brand components and applying operating concepts ensures full operation in the future.

Multiple benefits and aid capabilities:

Managing several pieces of equipment from a main computer in the office through ethernet (sending production orders);

Ability to receive and operate complex draws or cutting cycles programs;

Production / cost control through a total hour counter or by works, and a total area counter, by works or saw;

GSM or WEB text messaging system that lets you know that the job is done or if there are any errors in the cutting phase;

Signal emission to check the condition of equipment at a distance.

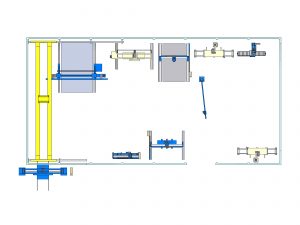

Foot Print

Equipment Read to Work Over Integral Chassis

The Standard Production Allows Increase Several Components in All Gammas

Radio control gives the operator more freedom of movement.

The flange is made to ensure that the pulleys system doesn’t reach the material.

The main screw is stainless steel.

An water projection fork in zinc treated iron is made to be removable

Allowing an easy change of the disc

Surface treatment is always done with a hot zinc projection base.

Metal side pillars are made in one piece.

An extension can be mounted to get close to the bench and provide smaller diameter discs.

This makes the equipment in the assembly taller to support larger diameters.

Water shields upon displacement of the rails may be provided to prevent the projection to the other side.

A support can be made to position the laser line above the cutting disc.

Centralized lubrication provided on plastic pipes with central connection elements.

Mesh reinforced rubber water hose, steel wire braided cables.

Water pressure switch to control cooling; Oil pressure switch in lubrication system, and air filters.

Junction box for axis cables and quick water connection.

Hydraulic compensators to provide an fast vertical displacement and also compensate for large saw diameters.

Flexible cables moved by the cable support rails.

The displacement carriage makes the connection between the bridge and the RAM. Very robust structure to support the enfort on columns work.

The Hercules Series is designed to have the highest cutting capacity overdue.

In the front tilt, the whole ram makes the movement by an axle connected to the displacement carriage.

Flag crane for working with suction cups or tweezers.

You can set the time on arm, capacity, electric or manual movement.

Industrial panel to allow work in industrial environment.