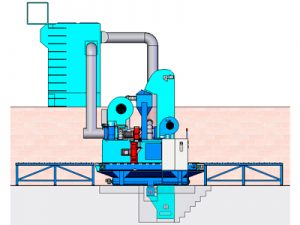

Shot Blasting With Alimentation

About

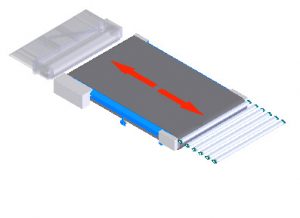

Equipment to provide irregular surfaces, from projection of stainless iron grain by blast process. Assembled with several turbines in order to make an even blast and maximize its capacity. It is possible to adjust the intensity of the blast.

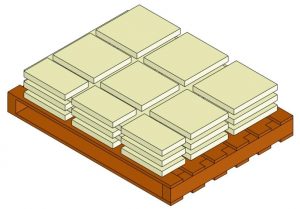

With roolers conveyors on charging process and download, by an mesh or rubber belt inside the equipment, the projected granet into the material, after collide goes down into the collect belt, that ones initiate the recovery process into the silo to provide an continuous supply.

An exhauster equipment provide the dust suction vacuum and filter the air, retains the stone particles inside it to posteriorly re-use if intend.

Technical Features

✓ Number of turbine projectors – 4 or 6 (inverter controlled)

✓ Maximum admissible height – 8,3/4 in / 22 cm

✓ Blasting capacity – 51 in / 1,3 mt or 2 meters (start on 23,1/2 in / 60 cm)

✓ Power of main motor – 11 Kw (15 Hp) / 22 Amp.

✓ Approximate minimum weight – 15,500 lbs / 17,000 Kg plus suction unity

✓ Maximum height required for operation – 216,1/2 in / 5,5 mt (depending of lift system)

✓ Blasting displacement velocity’s – max. 118 in / 3 mt / minute (inverter controlled)

Irregular Surfaces Production Over Conveyor Systems

Working Types

Blast , Flame , Shot , Vibratory Procedures to Unmask Irregular Surface

Flame and Blast On Travel Car

The Hammer head with rotation can be supplied starting on 3 units until 5 hammers, the choose depends of available supplied air to work on