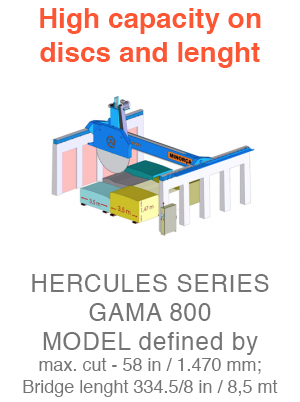

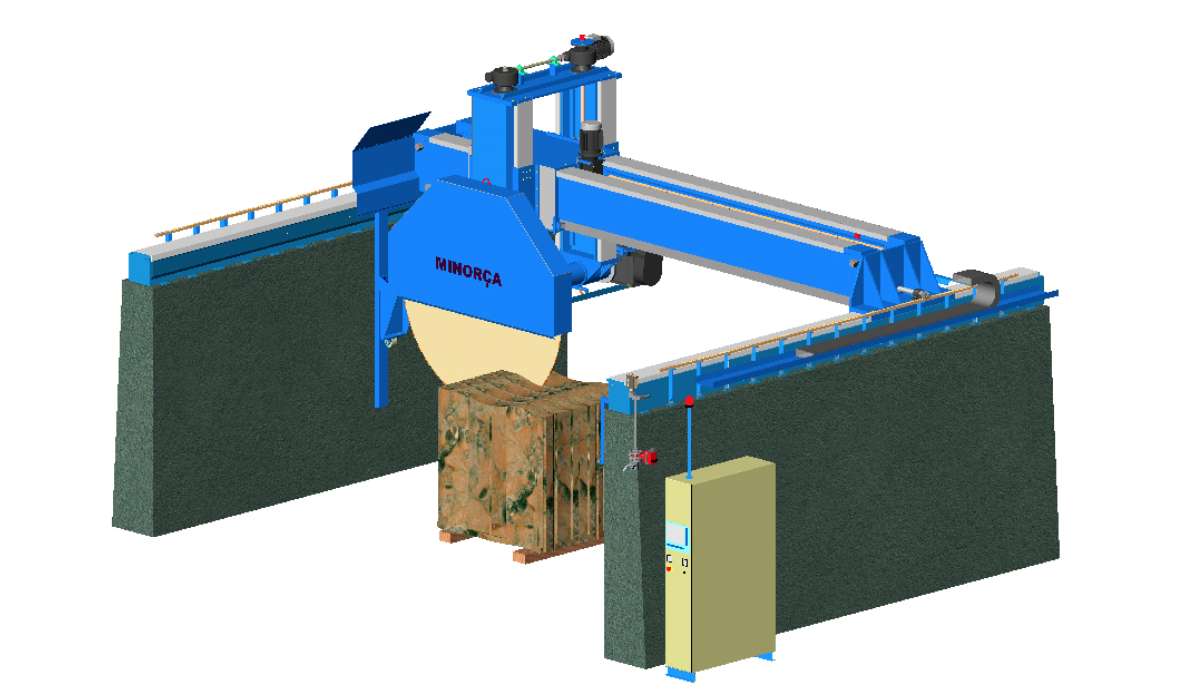

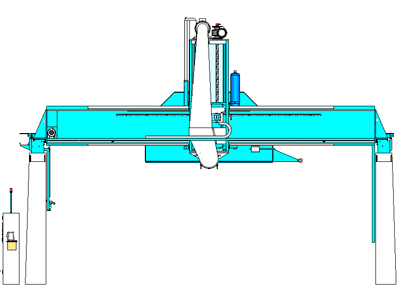

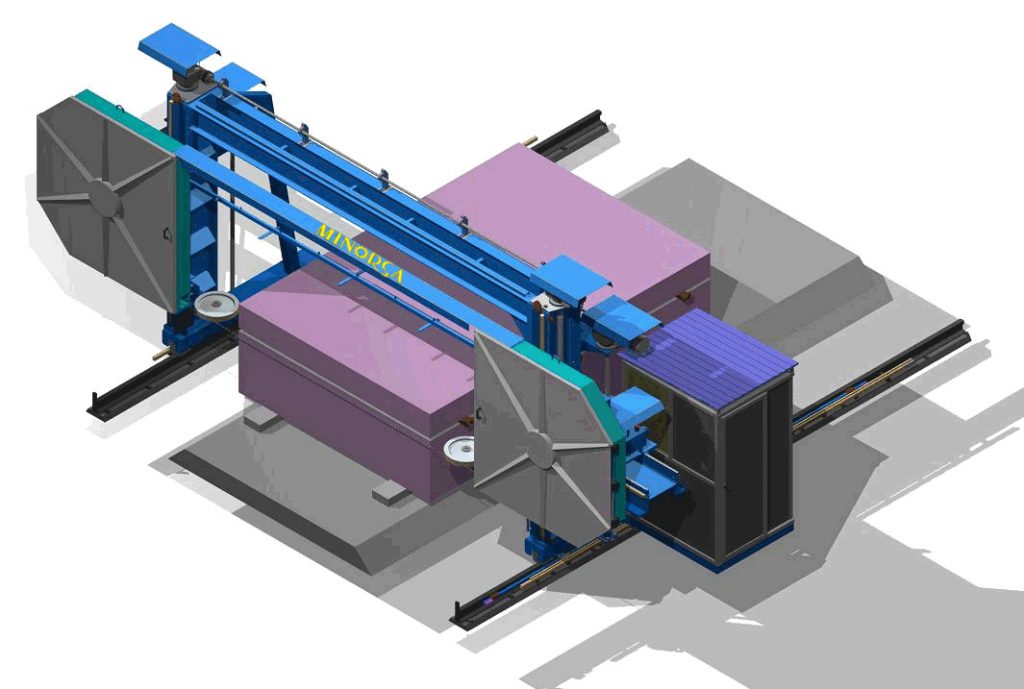

Double Ram Over Double Bridge Block Saw

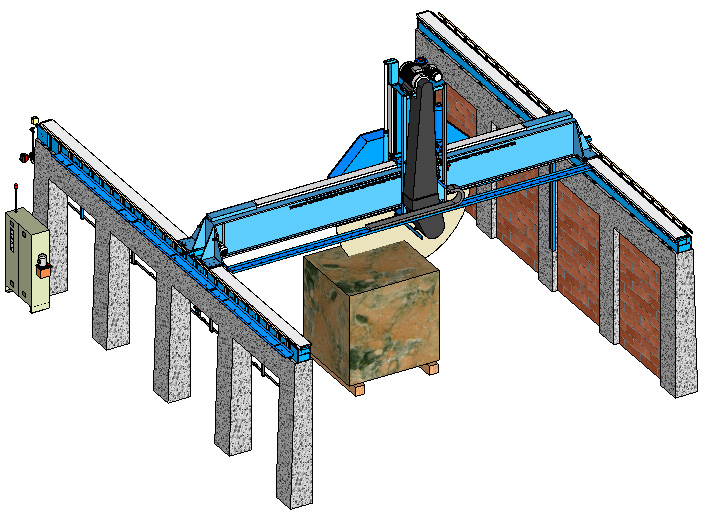

About

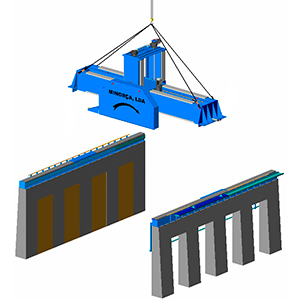

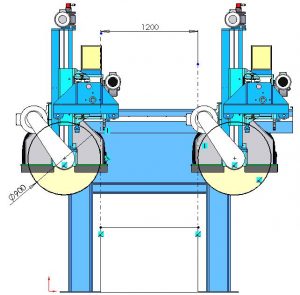

Allows cutting several blocks of different dimensions simultaneously. Assembled over concrete pillars providing distance of components to allow the loads process without the compromisse to be carefull with contact by blocs or fork loader.

The lateral rails supports an double bridge where works an travel cutting car with double rams connected on top and bottom, that travel car with connected points by the milling surfaces over 4 contact rails on each side. Supports the rams moving on vertical

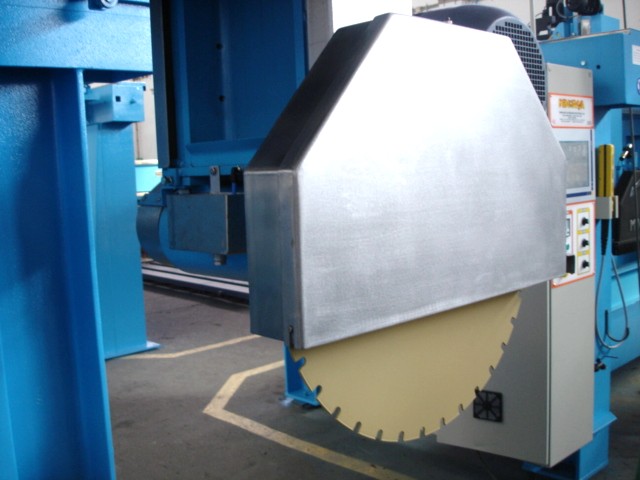

Based on robustness this equipment are able to cut the must hard granites in the world. With experience and tested components over more than 50,000 working hours we warranty the must efective and low cost saw to high thickness.

Technical Features

HIGH PERFORMANCE, MANUFACTURED IN DOUBLE, UNLIMITED POWER AVAILABLE

✓ Diameter maximum Vertical – 106 inch ( in ) / 2,7 meters ( mt )

✓ Maximum Cut Height (Flange 16 in / 40 cm)

45 in / 114 cm disc 106 in / 2,7 mt

✓ Regular Vertical Effective Travel – Z axis = 51 in / 1,3 mt

✓ Regular Cutting Capacity on Horizontal Axis = 122 in / 3,1 mt with max.disc

✓ Power Admitted on Cutting Motor Regular – 45 Kw (60 Hp) max.110 Kw (150 Hp)

✓ Approximate Minimum Weight – 30,200 lbs / 13,700 Kg

✓ Maximum Height Required over rails – 224,1/2 in / 5,7 mt

✓ Internal distance between rails: 260 in / 6,6 mt

✓ Maximum cutting speed shift – 531,1/2 in / 13,5 mt by minute

✓ Admitted peripheral speed of the cutting saw – 1,024 in / 26 mt or 1,850 in / 47 mt/second (will be selected to one specific material with 30 % oscilation to more or less)

✓ Displacement over lateral rails capacity: 323 in / 8,2 mt with 393,1/2 in / 10 mt

✓ Travel rails admitted – 216,1/2 in / 5,5 mt – 236 in / 6 – 334,1/2 / 8,5 – 393,1/2 / 10 mt ( Maximum length 78,1/2 in / 20 mt )

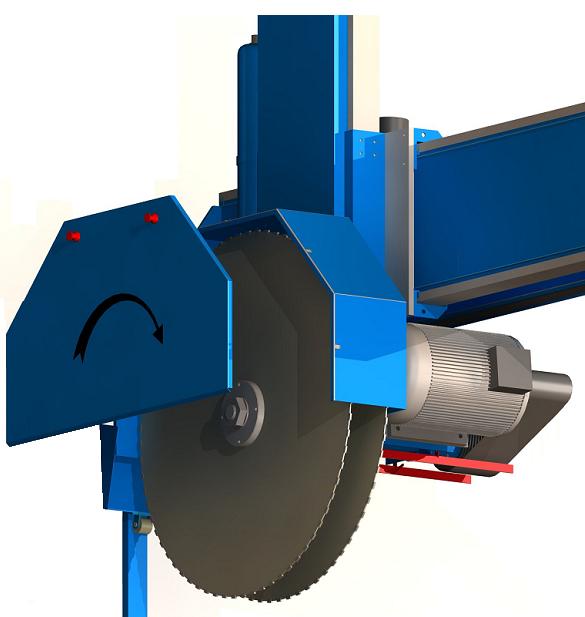

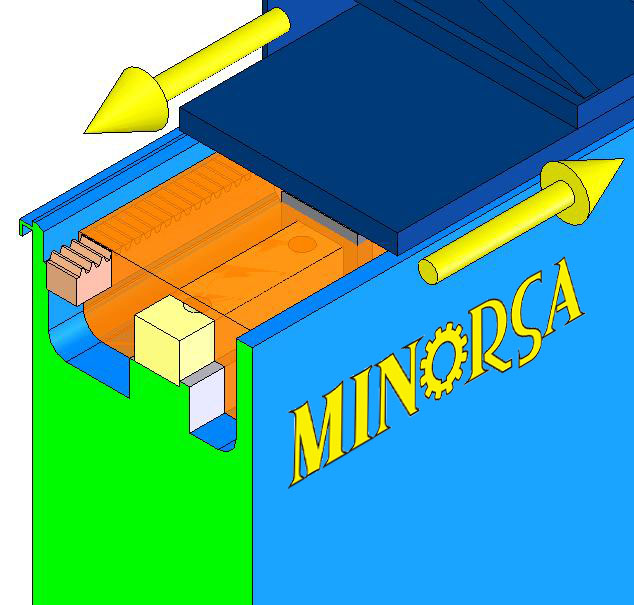

Saw on Double Ram Over Double Bridge

An frame manufactured all in double size as the double bridge with cutting capacities until 45in / 114cm

Bridge With 8 Contact Points

With security system

45 in / 114 cm disc 106 in / 2,7 mt

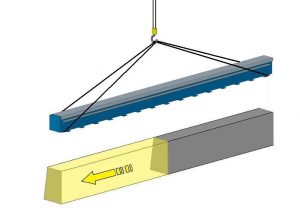

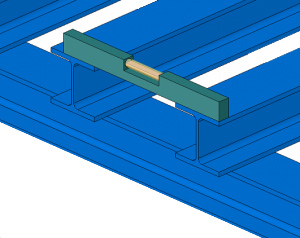

Multi disc over long shaft

Shaft with 11 in / 28 cm long – Spacers with 11 in / 28 cm diameter

13,3/4 in / 35 cm disc 47 in / 1,2 mt

15,3/4 in / 40 cm disc 51 in / 1,3 mt

25, 1/2 in / 65 cm disc 63 in / 1,6 mt

25,9/16 in / 65 cm disc 70,1/2 in / 1,8 mt

31,1/2 in / 80 cm disc 82,1/2 in / 2,1 mt

35,3/8 in / 90 cm disc 90,1/2 in / 2,3 mt

OR FULL AXLE / Shaft under carriage model.

Working Types

|

|

|

|---|---|---|

| Execute 90 Degrees Cutting Angle

By the use of an continuous rotation bench allowing 32 tons can execute both cutting sides |

Movement on Total Oil Bath Ability Improve the time on movement parts and dispense the lubrication check up |

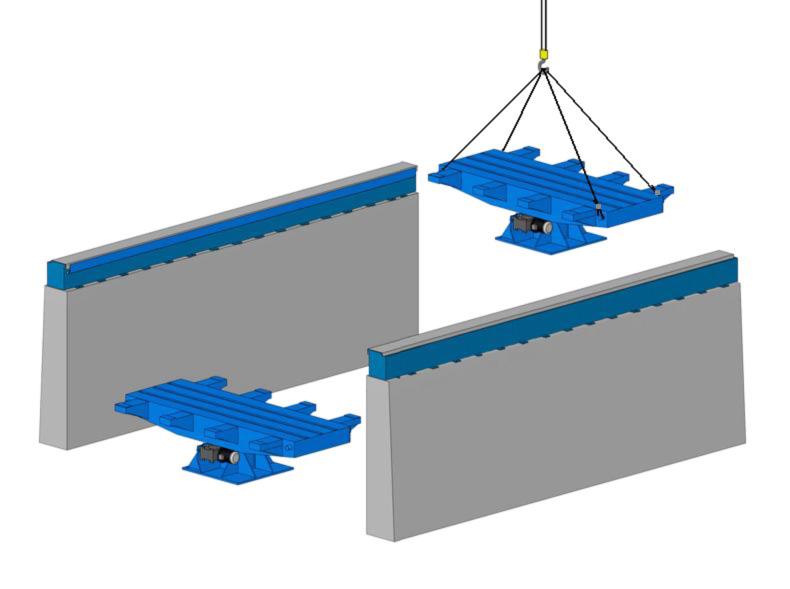

Double Bridge Ideal to Load With Fork Loader

Providing an Special Size Strengthened Until 472,1/2 in / 12 mt

Multi disc assemble

With a long and reinforced shaft, you can mount 3 or 4 discs, depending of the diameter and main power.

Multi disc on bridge

To increase the cutting capacity over set distances, you can mount multiple saws on the same body, which will allow an entire axis to insert the discs. These will be powered by a main engine with belt system to transmit the correct rotations. This system can be mounted on double bridge, depending on the intention. The start on 125 Hp / 90 Kw or up to 220 Hp /160 Kw, depending of discs quantity.

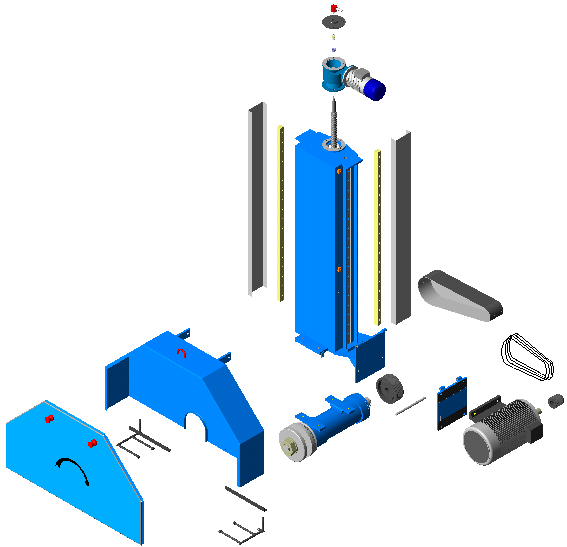

Can Set the Displacement on Lateral’s Until 787.1/2 in / 20 meters

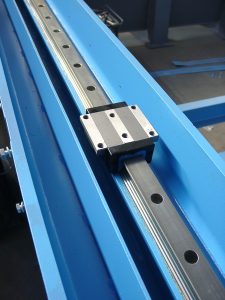

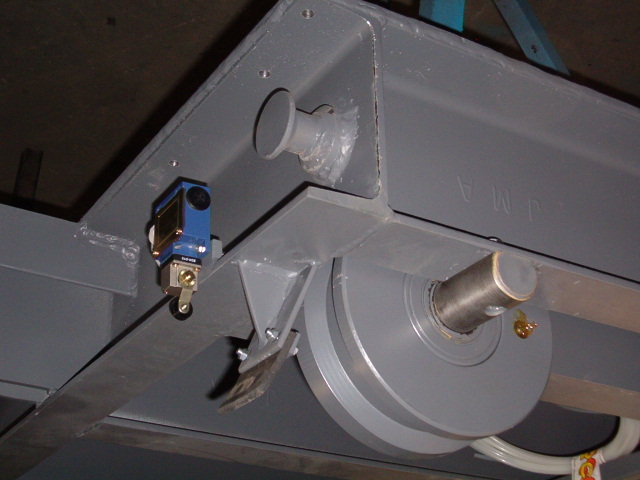

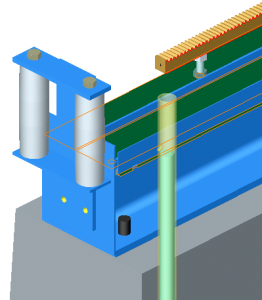

Side pillars are a component of extremely important equipment. An anti-resonance system was developed in these. As a way of eliminating micro vibrations caused by tools, they release a chatter that alters precision parameters as well as measuring the incidence of small marks on the material. On side of the electrical panel we put a constant coverage monitoring in linear bearing, which applies on a support surface. This is a large size to receive the load caused by cutting effort. The linear bearing can move in full oil bath, without twisting maintain a constant alignment of the bridge for displacing the cutting head.

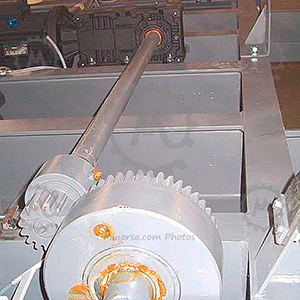

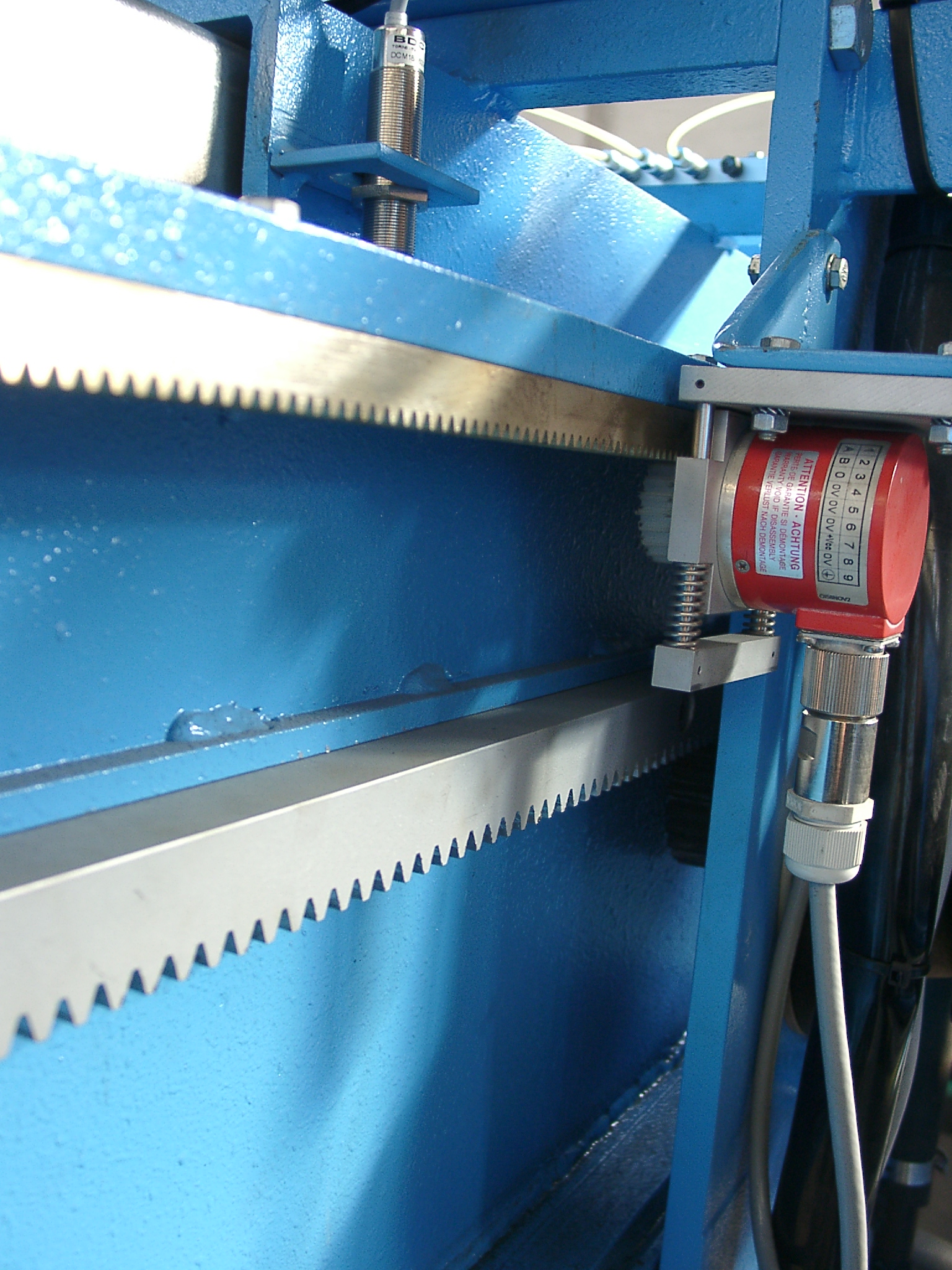

Assembled rack on both sides with adjustment

The weight of the rails is always the same regardless of bridge stress positioning, traction and alignment. With an oversized construction, we guarantee perfection on the side rails as well as the inner rails. All adjustable in positioning and fixed by iron bolts, the rails move from bottom to top of the gear, machining at once, ensuring perfect alignment of parts for a long time.

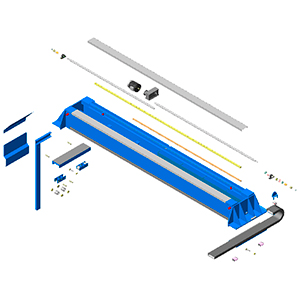

Stainless iron guards assemble

Can mount guards on stainless iron or bellows. We mount the bellows on small displacements, and the stainless 1/8 in. / 3 mm. in all others dimensions. On the top we screwed it and the displacement carriage has a bearing support to allow perfect movement on long distances.

Both pictures show the both sides. The interior has separate boxes to avoid the mud, for oil bath work, the side box has different dimensions on each side, on the mud side there is a system for removing resonance and on the other side the linear bearing guide for providing constant parallelism.

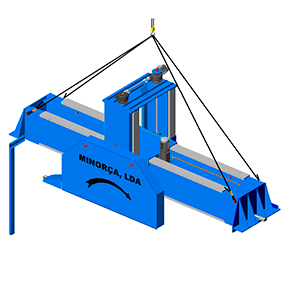

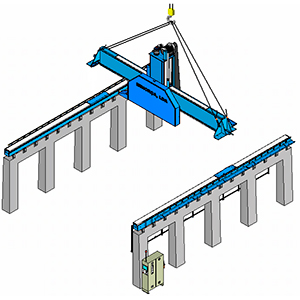

The conception of displacement cars on the rails is removable on assemble

We started using linear displacement bearing guides in 1993. Displacement systems have been developed and refined to increase the power of the cutting saw. The production is and to keeping equipment and finish quality.

Experience and knowledge enable us to ensure that this mechanism is the best option for exploring the equipment in all configurations with cutting benefits.

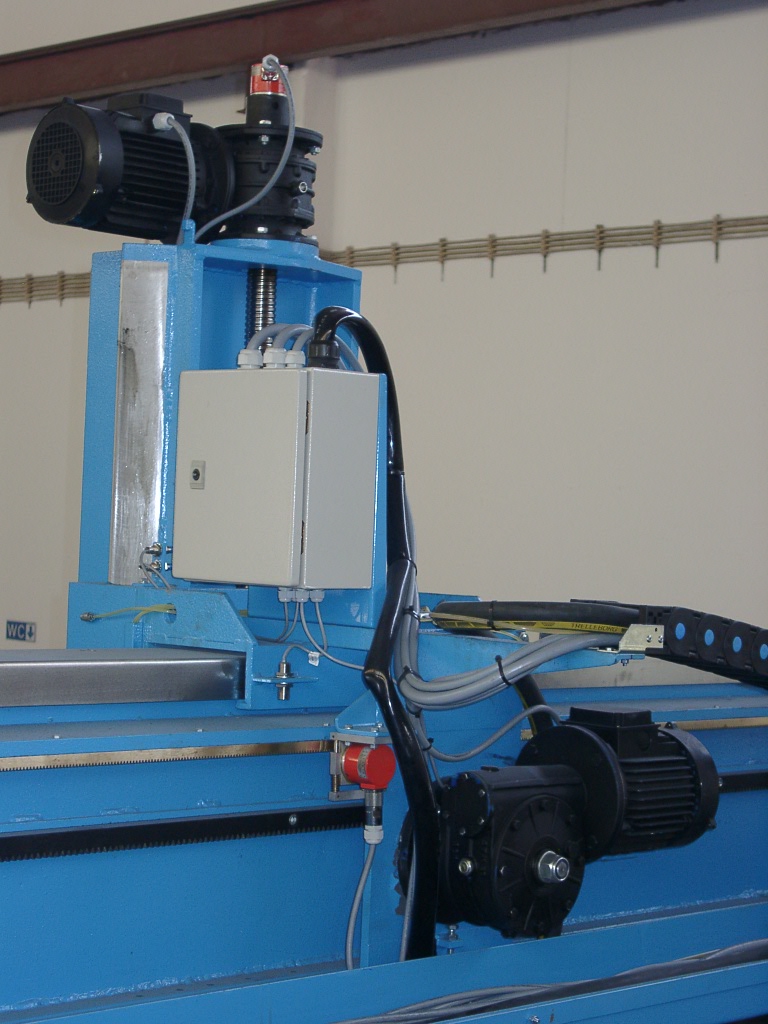

All equipments are total assembled on factory and subject into an exhausting test control

Small parameters are adjusted in the assembly process, parts are deposited in a transport box, plastics to cover the motors.

Machined surfaces on every alignment parts and support

Working on oversized displacement linear bearing guide with two bearings allows the perfection in all positions and increases the displacement velocity. There are two separate boxes, one can work with oil bath and the other removes the projected mud.

Standard manufacture and procedures

Hercules Series pieces are designed in series to improve their quality as a product, part and component that will integrate the equipment and thus build reliably. If you think in profit and production 24/7 at full time, assemble by working process to ensure the well final product, and check every part after placing it on several components to send to final address.

✓ Mounted over rails on floor

✓ Travel / displacement cut regulation by programming, with counting by encoder and electrical engine

(for more optional)

✓ Cutting portico displacement by using an electrical engine with and speed control. This allows for maximum displacement speed and great precision when positioning cutting measures

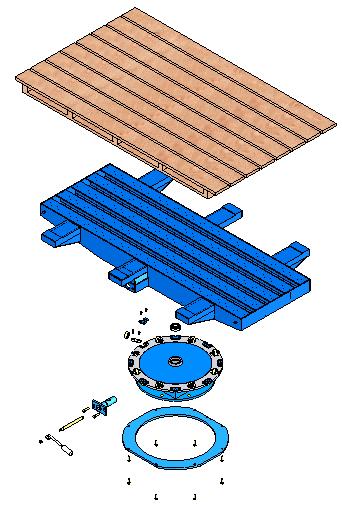

One Solid Travel Car in Ring Shape Provide the Constant Contact Also Alignment

With the development of compact cutting car with multi contact points since 1994, where we produced the first vertical double pillars saw, we have been improving the displacement of cutting car to this day. Using linear bearings displacement, double rack with pinion motorization, we provide the best level for customer work, with robustness for a fast-displacement car. (as shown in the initial image on right side).

With the development of compact cutting car with multi contact points since 1994, where we produced the first vertical double pillars saw, we have been improving the displacement of cutting car to this day. Using linear bearings displacement, double rack with pinion motorization, we provide the best level for customer work, with robustness for a fast-displacement car. (as shown in the initial image on right side).

The displacement of RAM is constantly supported on bridge cutting car

A displacement cutting car in ring shape, can support the contact between 12 points. The effort origined on high hardness granites is extreme, with this proven solution we supply the proper saw to hard granite cutting.

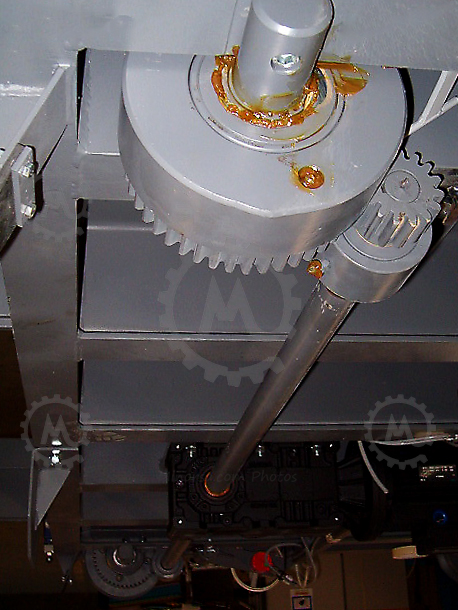

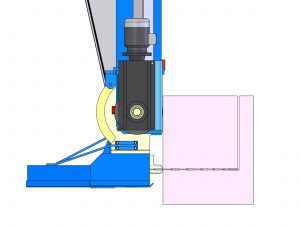

Gearbox Transmission to Provide Correct Revolutions On the Saw

The displacement cutting car can receive high power motors and work by an gearbox on high saw diameters.

✓ All contact surfaces are machined

✓ Cutting saw descent control through a pair of screw shafts with gear boxes.

✓ Counting system by means of an encoder

✓ An entire shaft connected under the double Ram into the gearbox

✓ Displacement system using linear bearings as guides allowing hardly any friction and increased cutting power

✓ All of the control and speed changes are made by means of a variable inverter drive

Best Optimize on Working Table

For each type of work, we have a more suitable bench solution

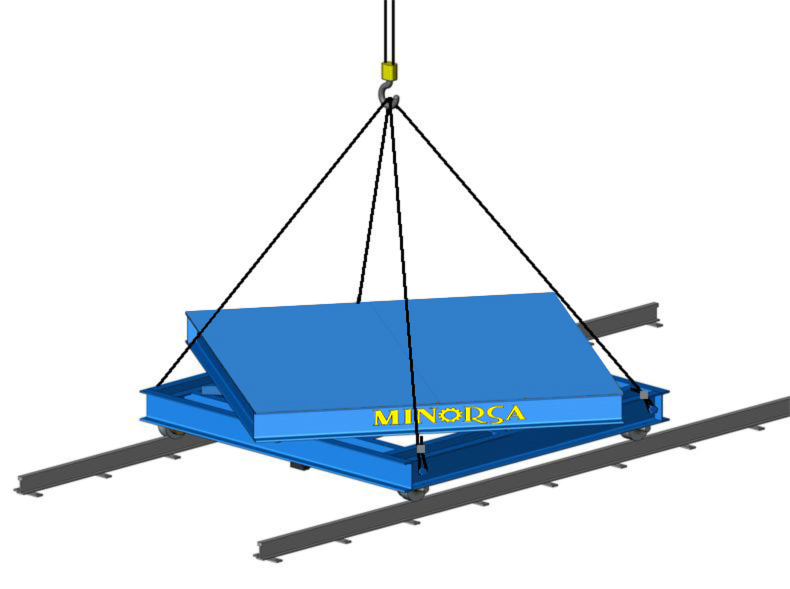

Continuous rotation bench allowing 32 tons.

Ideal for transferring materials out of the machine without interruptions. The rotation is electric and works on a fabricated ring, on the outside or the base of the must. he ring is on conical shape to provide of 98,1/2in / 2,5mt and can assemble side arms to provide 118 in / 3m, the working height start on 29,1/2in / 75cm with the train rail on concrete to elevate from water on floor.

Measure system on moving benchs with encoder coupled with an wheel with rubber pressed by an aligned spring to work directly over the rail.

Moving bench allowing 32 tons

Often used to transfer block from outside into the machine, it is also a solution to be used on the second bench with the exchange of workspace on another table to provide multi-head work used with metering system on stationary saw machines. The surface has 98,1/2 in / 2,5 mt by 59in / 1,5m and can assemble side arms to provide 78,1/ 2 in / 2 mt, the working height start on 19,1/2in / 50cm with the train rail on concrete to elevate from water on floor.

It has an easy wheel access through a bolted axle, a machined button surface to receive gearbox, and also axle on the wheels. It works with carriage on a pair of sprockets. This model started shipping in 1988 and it was designed to be simple to handle and to able to incorporate the various saw models. It has a solid structure, built in several sleepers to ensure the installation of weights in all positions.

An second bench can be set

With an Proper Bench Provides Charging Capacities

Can assemble on an Block Saw with monoframe Fixed multiple benchs, that allow the rotation of the material, the charge bellow an portico crain, or just because of the occupied space.

Over Concrete The Equipment Load Is Faraway Of Mobile Parts

The maximum optimization on Hercules saw gamma’s presented as option dedicated on bloc saw

The Most Rentable Saw Middle Cutting Bloc

The Hercules Series to Explore the Maximum on Stone Saw Work

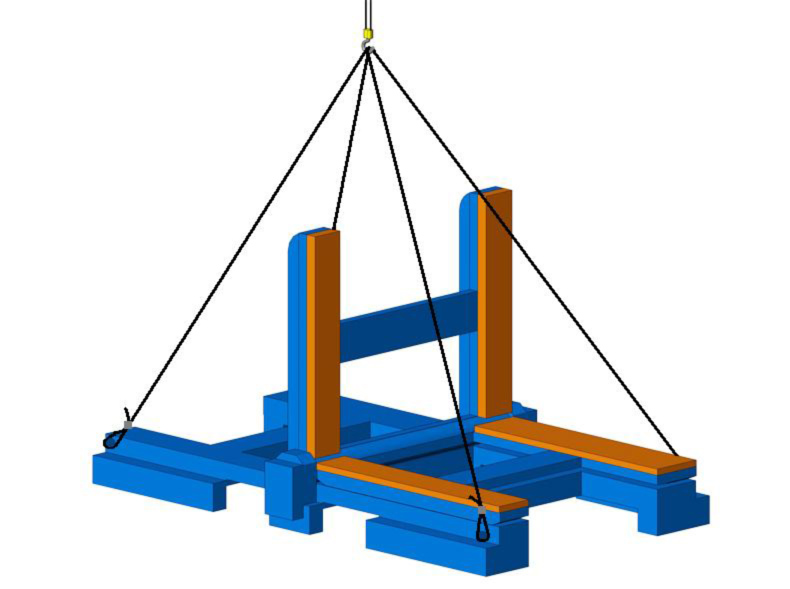

Fast and Easy

Assemble in 6 steps

Raise the bridge to the side-shift cars, bolt all sides of the bridge and check movement manually and without friction. Mount components and accessories on ram. Take final tests and work specific training, and it’s ready to work 24/7.

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

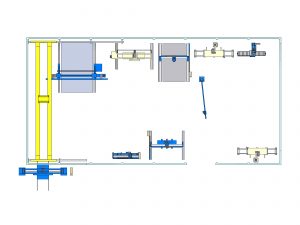

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Standard And Tested Components Offers Reliability

The Hercules series adopts the principle of using common parts by changing their sizes by gammas.

Standard Parts In:

Working tables

The intention is to indicate that the parts and components produced starting in a project were subjected to intensive tests over 50 thousand hours. In the Hercules series they are used according to a manufacturing plan, from individual design of the pieces to their join assembly, with an accessory or component that will be combined with other to get a reliable and cost-effective equipment, easy to operate and maintain, and usable to its full capacity either in production or in its profit.

Cutting heads

All the components are designed to be interchangeable between the Hercules Series. Is this the concept that we intend to present: developed, tested, interchangeable, capable of receiving various upgrades, potential for expansion either in power, and that allowing the accessory exchange.

Measure system with independent counting

Based on the concept of making full use of head swapping equipment for multitasking, on the same bridge can be mounted more than one ram model. It is possible with two side supports, with one of two powertrain systems, with two transmission systems or with one of two control systems, but always with the highest quality products.

Independent gear counting system, which increases reading accuracy without the use of transmission elements, allowing positioning of the displacement elements/axes with a maximum error of 2 tenths of a millimeter.

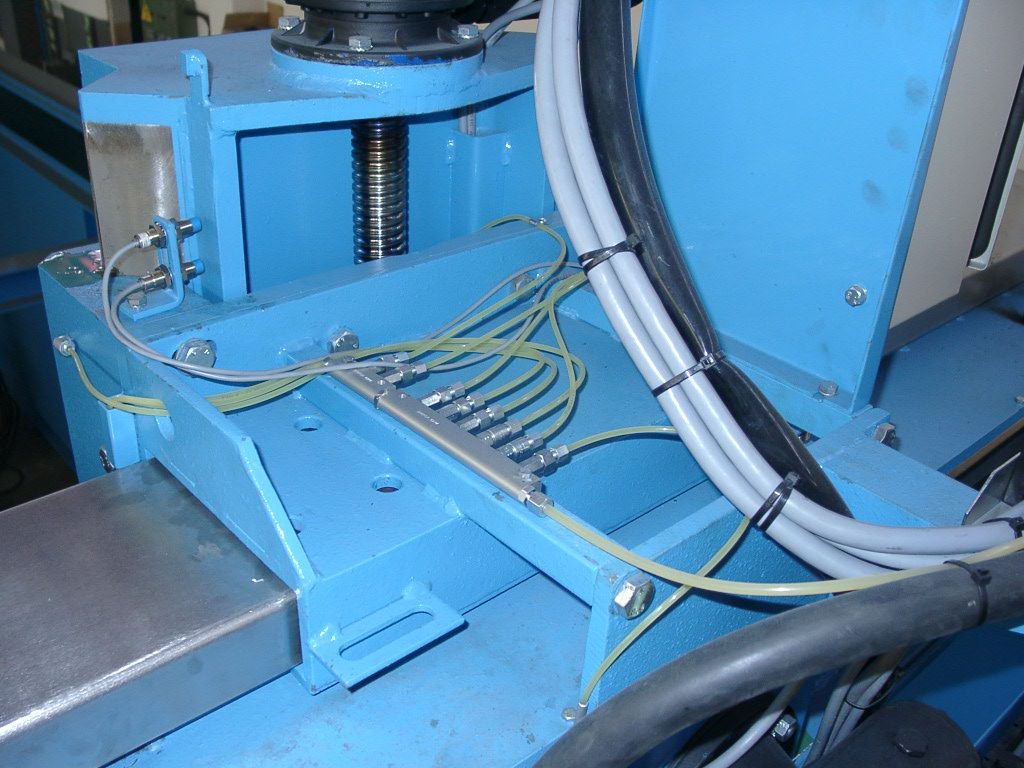

Junction box for shaft cables.

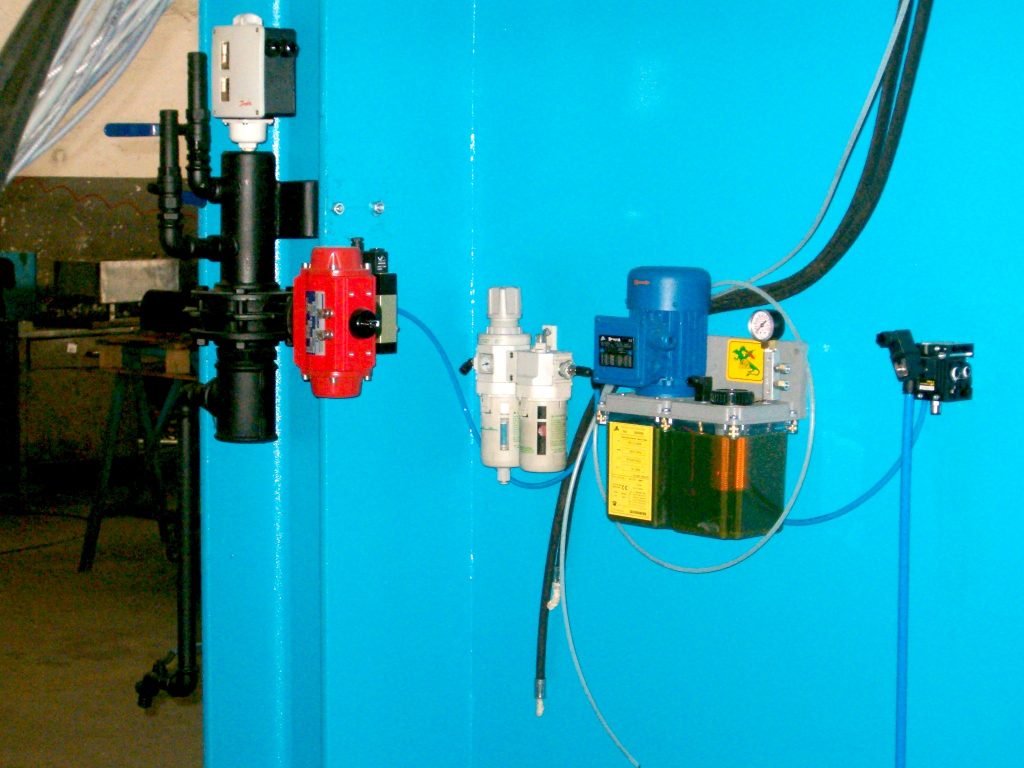

Automatic lubrication on all displacement points: water on/off automatic valve

The auxiliary components are also selected for their good operation and easy maintenance, and the security systems are assembled for easy identification and protection from events.

Power failure recovery (position and status memory) to continue working automatically, saving time and materials to be cut;

Automatic cut-off stop protection, if material gets stuck, slow down or at the end of the program;

Automatic axle stop/protection in case of mechanical anomalies during operation;

Displacement stops cease working to avoid programming or operation errors;

The equipment stops when opening the electrical panel;

Low voltage manual control switch to protect operator;

Electric protection by using magneto thermal switches (without fuses);

Regulated power supply, protecting low voltage circuits against power surges;

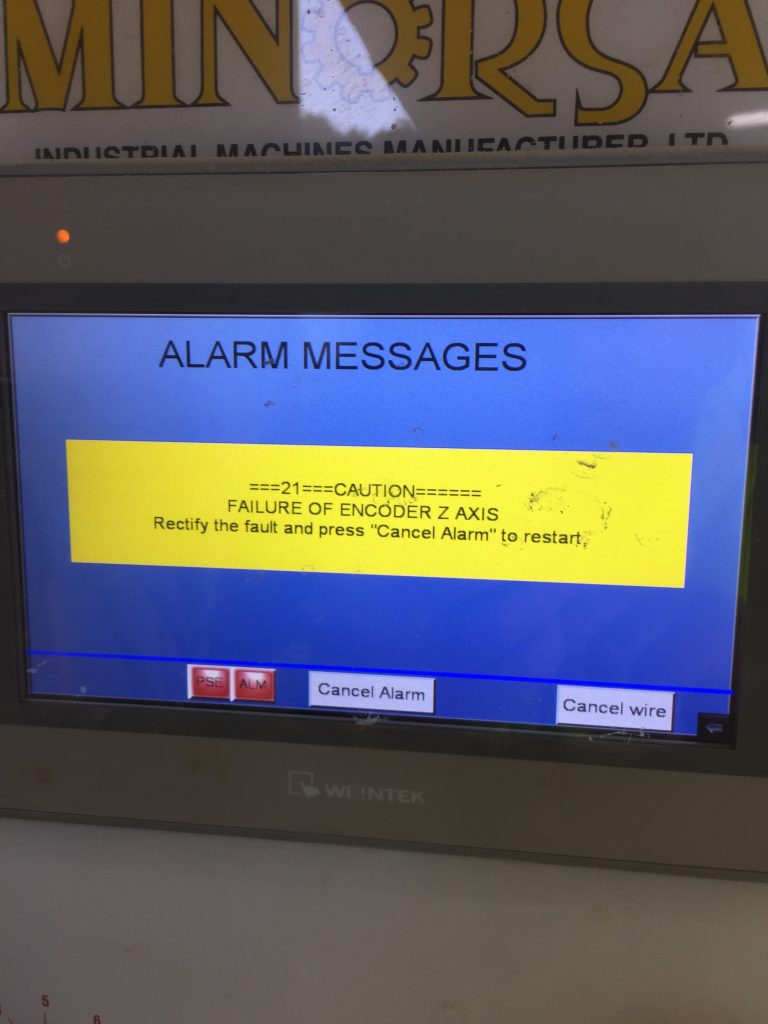

The equipment stops after encoder pulse count failure or contactor obstruction;

Horizontal displacements in oil bath capacity.

Automatic lubrication system with times, which allows keep the equipment lubricated at all its constant movement points, without the need operator interventions with oil pressure switch in case of pressure loss in the circuit.

The displacements can be fully embedded in oil bath, eliminating supervision and increasing time between periodic maintenance. Thus, allow increasing its lifetime.

Laser with continuous focus

Accessories with laser focus, allows the use of laser for better alignment of the initial positioning on the pieces to be cut. One of its features is the individual variable speed transmission, which allows for more precise adjustment of speed and position. This also has water shut-off valves fitted as standard unless otherwise requested.

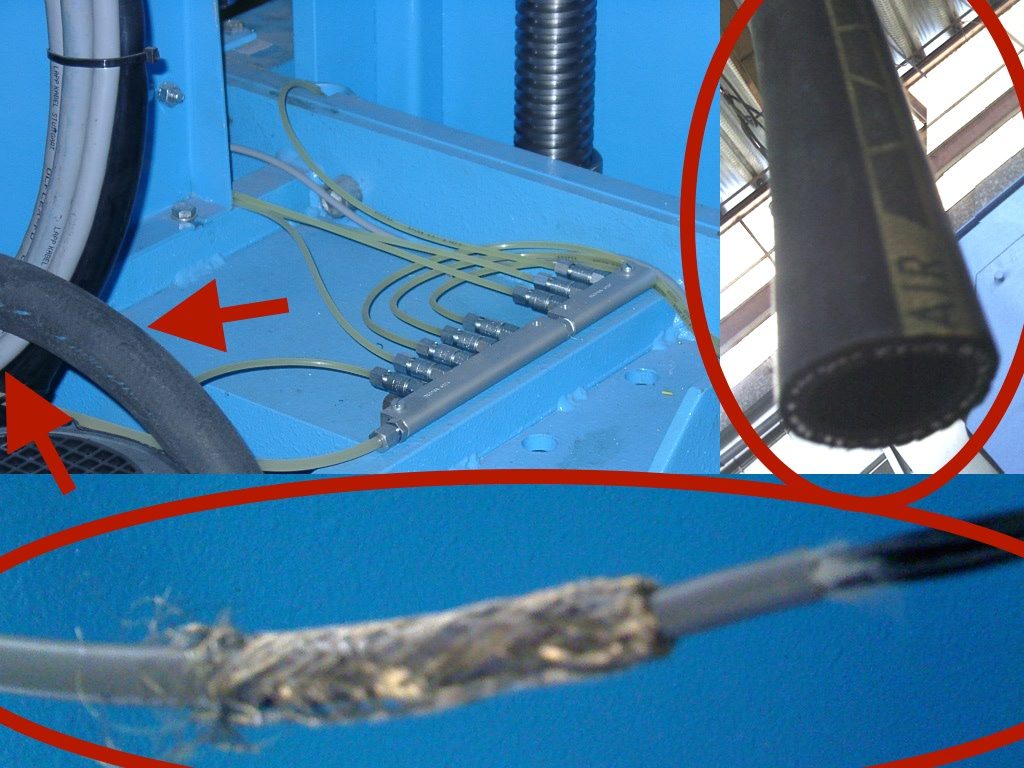

Water pressure system control/protection on cables by cover mesh/pressure water pipes

Special electric cables with mesh sheathed, moved through the cable supporting rails. Measure Encoder component with braided wire mesh cables (counting system) to protect against power surges. The base installation also has inner lined water cables consisting of a mesh reinforced rubber hose inside. Shields and rails for collecting the oil coming from lubrication of material used for cutting. Water pressure switch to control cooling and washing of the saw. (Placed on top of pillar for greater accuracy).

Electric board disconnected of equipment

A pit dimensioned with spaced components and embedded screen. The plate is separated from the machine to avoid vibrations and has easy access, because it will be installed close to the floor. This electrical panel is built in our facilities in compliance with all CE regulations.

Electrical panel ventilation system with temperature control. Software under development to facilitate data entry and reading, based on operator feedback and questions. Mains fault detection system.

Standard components of well reputed brands

Using reputable brand components and applying operating concepts ensures full operation in the future.

Multiple benefits and aid capabilities:

Managing several pieces of equipment from a main computer in the office through ethernet (sending production orders);

Ability to receive and operate complex draws or cutting cycles programs;

Production / cost control through a total hour counter or by works, and a total area counter, by works or saw;

GSM or WEB text messaging system that lets you know that the job is done or if there are any errors in the cutting phase;

Signal emission to check the condition of equipment at a distance.

Features

-Automatic Travel Inversion System

When activated, it does an inversion everytime it detects there is no more stone to be cut. This function overrides other commands, i.e. it ignores other cuts programmed in the console and/or travels later set by the control panel. This function has depth parameters that disable the operation (necessary for the first cuts due to the irregular stones surface), inversion timer (necessary due to the irregular sides of the stones) and offset current (necessary for situations where there is saw cut capacity variations and stone hardness). This function enables to significantly decrease the time it takes to cut a stone.

– Saw opening system and progressive unlocking

These 2 functions are simultaneously activated. The first function consists in an automatic decrease of the passages should there be a higher consumption value different from the one set by the operator (it depends on the saw hardness and characteristics). Decreasing the passages will allow the saw to open and increase its performance. After the machine detects a decrease in the consumption values (because the saw is already opened), the function will automatically reset the passage to the value initially set by the operator. The consumption value from which the machine starts to increase passages also depends on a parameter set in the console. This function can also be used for decreasing equipment cutting time, i.e, it allows for the operator to programe passages slightly above the initially set values, due to the equipment later automatically setting the passage according to the programmed current control value.

The second function consists in a deceleration of the cut in cases of extreme consumption (parameter set by the operator) due to overcurrent caused by blockage/jamming of the saw, which sometimes occur in the end of the cut or because the stone has areas that are significantly harder. After this happens, the machine starts to slowly and gradually accelerate until it hits the previously set speed. The deactivation of this slow acceleration process can be done by enabling/disabling the function or by simply changing the speed knob position. Decreasing speed will also reduce the chance of the machine stops due to overcurrent, avoiding any unnecessary interruption of the production that can happen in the absence of the operator, but it is particularly helpful during nighttime production. By safety reasons, in case there is an extreme consumption, the machine automatically deactivates the inversion function.

-Travel stop pre-detection system and error due to encoder malfunction/error.

The equipment is continuing monitoring its position. By checking that the bed is closer to the supports, it starts to decrease speed before stopping completely by activation of the travel stop sensors. This function allows greater speed in the cutting area and an increase in the lifespan of the equipment, as it makes it unnecessary to decelerate on short ramps (sudden stops). By monitoring impulse counting it is possible to avoid collision due to error or encoder malfunction.

-Automatic Function/Single Cut

The equipment allows doing a single cut by setting dimensions to “Zero” or through a dedicated page.

-Measure displacement function

Allows moving the bridge to its initial cut position.

-Saw torsion prevention system

To avoid torsions in the saw caused by higher passages in the first cuts, the operator has the option to programe lower passages until the machine hits a certain cutting depth.

– Monitorings

– Calculations of the cutting area by stone and total accumulated by saw diameter

– Cutting time by stone and cutting time total

– Cutting engine power consumption through an analogue meter and virtual meter (console)

– Speeds monitoring in m/min (meters per minute)

– Quota/axle position monitoring in mm (millimeters)

– RPM monitoring (Rotations per minute)

– Programming speeds and saw diameters

The operator will be able to select the rpms of a certain saw through a simple and intuitive selection out of a pre-programmed diameter and saw speed chart.

– Cycle programming options

The operator can choose a cycle where priority is given to the axis cut or vertical axis during inversion (Z after Y or Y after Z).

The operator can set different passage values for different cutting directions.

– Recovery in case of power failure

The equipment memorizes the programmed cut in case of a power failure.

– Change of the cut travel using the control panel

The equipment allows increasing or decreasing the cut travel set in the console, by memorizing the beginning and the end of the cut.

-Anti-collision protection system

By activating the protection bar the equipment does a return movement and positions itself for the next cut. This allows the equipment to continue with the programmed cuts, avoiding any unnecessary interruption of the production in the absence of the operator, and is particularly helpful during night-time production.

-Alarm and protection systems with memory

The equipment has 23 safety alarms. It is also possible to check the Date and Time of the Alarm on a console dedicated page.

– “Normally Closed Circuit” sensors

This operating logic allows monitoring and activating the alarm in case of error or interruption of the electric sensor signal.

– SMS Alert System (optional)

The equipment can also include an sms sending system to any mobile phone, showing a total of 7 states (Alarms and Equipment Alerts).

– Technological Update

All of the characteristics and functionalities are subject to change whenever Minorca considers being relevant to upgrade the equipment.

Machine Dimensions Overall Occupied Space

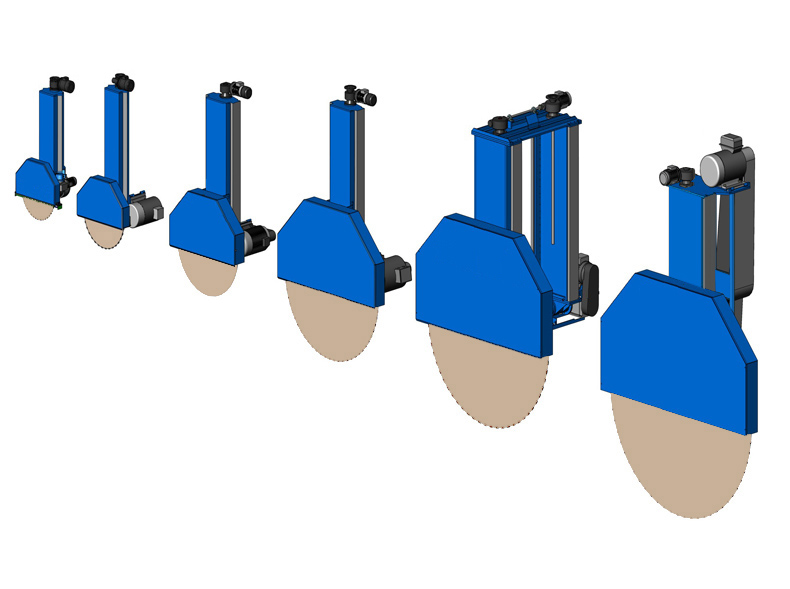

Accommodate Slipping

The Standard Production Allows Increase Several Components in All Gammas

The flange is made to ensure that the pulleys system doesn’t reach the material.

The main screw is stainless steel.

An water projection fork in zinc treated iron is made to be removable

Allowing an easy change of the disc

An extension can be mounted to get close to the bench and provide smaller diameter discs.

This makes the equipment in the assembly taller to support larger diameters.

Centralized lubrication provided on plastic pipes with central connection elements.

Mesh reinforced rubber water hose, steel wire braided cables.

Water pressure switch to control cooling; Oil pressure switch in lubrication system, and air filters.

Junction box for axis cables and quick water connection.

Water projection stopper with rotation movement to increase the displacement length.

Industrial panel to allow work in industrial environment.

Block Tilt Bench

Over Long Rails The Horizontal Saw Produce Better Cutting Quality

Assemble lateral cable support wheels can displace the total equipment on lateral over rail and provide an cut with maximum capacity, better quality and maximum work dimensions

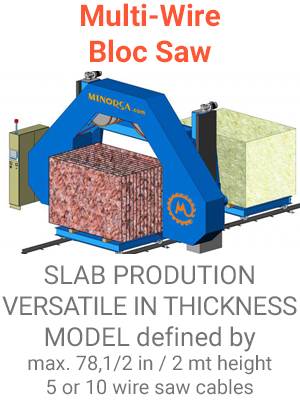

The working option with Several Wires at same time

Our development inside over high thickness slab production. Allows cutting several blocks of different dimensions and stone types simultaneously. Greater cut capacity using less space, no need for huge foundations.

The Gantry structure allow an perfect union of all components, since the lateral twin pillars connected over creating an perfect ring, that supports the vertical travel shafts connected into the wheels support car, that ones are moved by gearbox to allow the slow displacement on cutting process and also improves the fast velocity to make the repositioning.