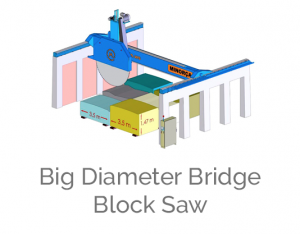

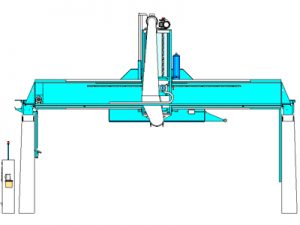

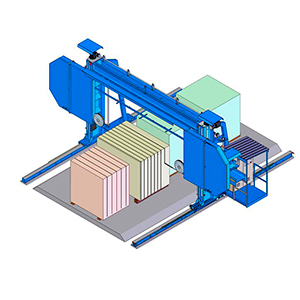

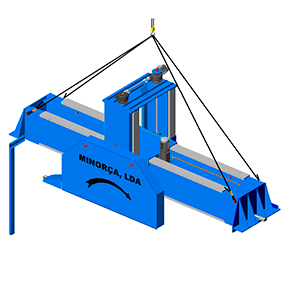

Big Diameter Bridge Block Saw

About

P.L.C.( programmable)

Programming and command console.

Control panel for remote control.

Junction boxes and waterproof cables in several parts of the equipment.

– Surface Treatment And Paint Job

All structure components are steel grit blasted, hot-zinc coated, painted with an anticorrosion primary, adding a textured coat with rubber particles and ending with a top layer of anti-rust enamel.

Features

-Automatic Travel Inversion System

When activated, it does an inversion everytime it detects there is no more stone to be cut. This function overrides other commands, i.e. it ignores other cuts programmed in the console and/or travels later set by the control panel. This function has depth parameters that disable the operation (necessary for the first cuts due to the irregular stones surface), inversion timer (necessary due to the irregular sides of the stones) and offset current (necessary for situations where there is saw cut capacity variations and stone hardness). This function enables to significantly decrease the time it takes to cut a stone.

– Saw opening system and progressive unlocking

These 2 functions are simultaneously activated. The first function consists in an automatic decrease of the passages should there be a higher consumption value different from the one set by the operator (it depends on the saw hardness and characteristics). Decreasing the passages will allow the saw to open and increase its performance. After the machine detects a decrease in the consumption values (because the saw is already opened), the function will automatically reset the passage to the value initially set by the operator. The consumption value from which the machine starts to increase passages also depends on a parameter set in the console. This function can also be used for decreasing equipment cutting time, i.e, it allows for the operator to programme passages slightly above the initially set values, due to the equipment later automatically setting the passage according to the programmed current control value.

The second function consists in a deceleration of the cut in cases of extreme consumption (parameter set by the operator) due to overcurrent caused by blockage/jamming of the saw, which sometimes occur in the end of the cut or because the stone has areas that are significantly harder. After this happens, the machine starts to slowly and gradually accelerate until it hits the previously set speed. The deactivation of this slow acceleration process can be done by enabling/disabling the function or by simply changing the speed knob position. Decreasing speed will also reduce the chance of the machine stops due to overcurrent, avoiding any unnecessary interruption of the production that can happen in the absence of the operator, but it is particularly helpful during nighttime production. By safety reasons, in case there is an extreme consumption, the machine automatically deactivates the inversion function.

-Travel stop predetection system and error due to encoder malfunction/error.

The equipment is continuingly monitoring its position. By checking that the bed is closer to the supports, it starts to decrease speed before stopping completely by activation of the travel stop sensors. This function allows greater speed in the cutting area and an increase in the lifespan of the equipment, as it makes it unnecessary to decelerate on short ramps (sudden stops). By monitoring impulse counting it is possible to avoid collision due to error or encoder malfunction.

-Automatic Function/Single Cut

The equipment allows doing a single cut by setting dimensions to “Zero” or through a dedicated page.

-Measure displacemente function

Allows moving the bridge to its initial cut position.

-Saw tortion prevention system

To avoid tortions in the saw caused by higher passages in the first cuts, the operator has the option to programme lower passages until the machine hits a certain cutting depth.

– Monitorings

– Calculations of the cutting area by stone and total accumulated by saw diameter

– Cutting time by stone and cutting time total

– Cutting engine power consumption through an analogue metre and virtual metre (console)

– Speeds monitoring in m/min (metres per minute)

– Quota/axle position monitoring in mm (millimetres)

– RPM monitoring (Rotations per minute)

– Programming speeds and saw diameters

The operator will be able to select the rpms of a certain saw through a simple and intuitive selection out of a pre-programmed diameter and saw speed chart.

– Cycle programming options

The operator can choose a cycle where priority is given to the axis cut or vertical axis during inversion (Z after Y or Y after Z).

The operator can set different passage values for different cutting directions.

– Recovery in case of power failure

The equipment memorizes the programmed cut in case of a power failure.

– Change of the cut travel using the control panel

The equipment allows increasing or decreasing the cut travel set in the console, by memorizing the beginning and the end of the cut.

-Anti-collision protection system

By activating the protection bar the equipment does a return movement and positions itself for the next cut. This allows the equipment to continue with the programmed cuts, avoiding any unnecessary interruption of the production in the absence of the operator, and is particularly helpful during night-time production.

-Alarm and protection systems with memory

The equipment has 23 safety alarms. It is also possible to check the Date and Time of the Alarm on a console dedicated page.

– “Normally Closed Circuit” sensors

This operating logic allows monitoring and activating the alarm in case of error or interruption of the electric sensor signal.

– SMS Alert System (optional)

The equipment can also include an sms sending system to any mobile phone, showing a total of 7 states (Alarms and Equipment Alerts).

– Technological Update

All of the characteristics and functionalities are subject to change whenever Minorca considers being relevant to upgrade the equipment.

Technical Features

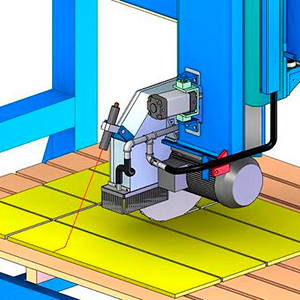

EQUIPMENT WITH MECHANICAL ORGANS AWAY FROM THE BLOCKS

✓ Maximum cut height : 1,235millimeters (1,475 millimeters with 3,5mt.) (for more optional)

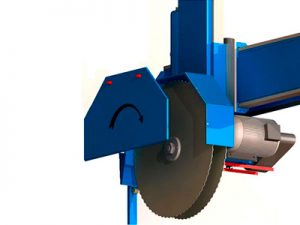

✓ Cutting saw support bracket : 500mm (550mm)

✓ Cutting head Z-axis: 1,400mm (1,700mm) (for more optional)

✓ Cutting saw descent control through a speed regulator / (inverter / frequency converter), counting system by means of an encoder and stop control using a electric engine with brake and an hydraulic compensator.

✓ Cutting saw descent control through a speed regulator / (inverter / frequency converter), counting system by means of an encoder and stop control using a electric engine with brake and an hydraulic compensator.

✓ Cut travel : above 3,600mm (for more optional)

✓ Travel / displacement cut regulation by programming, with counting by encoder and electrical engine

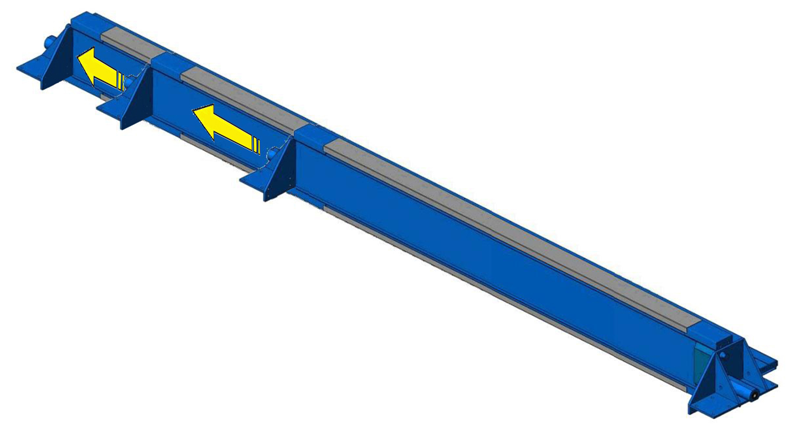

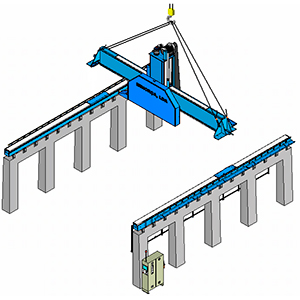

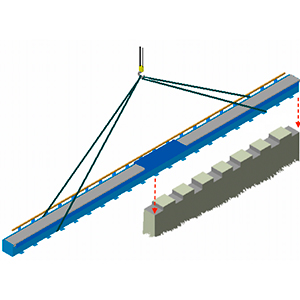

✓ Displacement travel and block placing capacity: 4,800mm with 6 meters supports (for more optional, only on concrete pillars with 6, 8,5 or 10m.)

✓ Mounted only over concrete pillars with 6,000mm (or more as optional) long supports.

✓ Cutting bridge displacement by using an electrical engine and speed control. This allows for maximum displacement speed and great precision when positioning cutting measures.

✓ Cutting engine power at 50hz = 37 Kw / 50 Cv (72 amps maximum) (55kw until 90kw)

✓ Use of pulleys and V-belts for the saw support spindle

✓ Equipment weight: approximately 15,000 kg

✓ Maximum operating height: 6,500mm

✓ Internal distance between supports: 8,100mm (8,6mt / for more optional)

✓ Maximum cutting speed: 14 METRES / MINUTE

✓ displacement system using linear guides allowing hardly any friction and increased cutting power.

✓ Cutting saw minimum peripheral speed: 26 metres /second

✓ All of the control and speed changes are made by means of a variable drive.

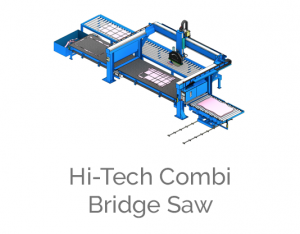

Main Feature & Related Equipment

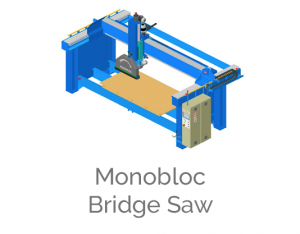

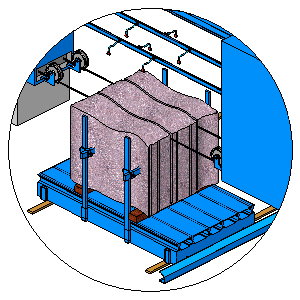

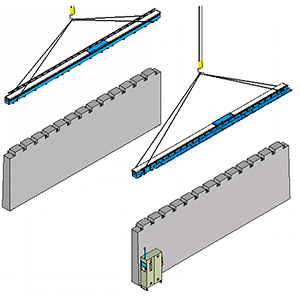

Block Cutter Saw on Mono Bridge Concept

That Models are able to cut blocks until 58 inch / 147cm with an low production cost.

Can also be adapted to other machines & if you intent please see any follow machine

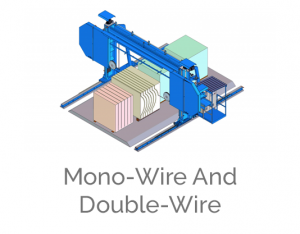

Bi-Wire System

Possibility to make double cut in one movement, allows the positioning of second wheel distance, that system it’s assembled on monowire frame.

Can also be adapted to other machines & if you intent please see any follow machine

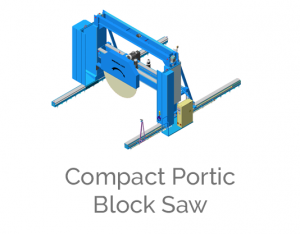

Monowire Cutting Machine

It allows the vertical cut until 89 inch / 226 cm, also can vertical profile and work with Bi-wire system, can work on portico system on several blocks or on trolley system.

Can also be adapted to other machines & if you intent please see any follow machine

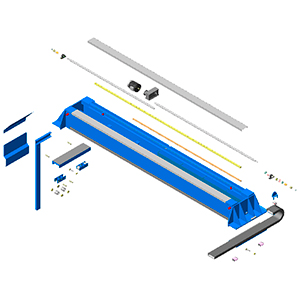

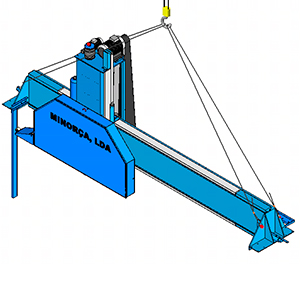

Several Length on Bridge

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

Mono Bridge Block Cutter, Fast and Economic

Can also be adapted to other machines & if you intent please see any follow machine

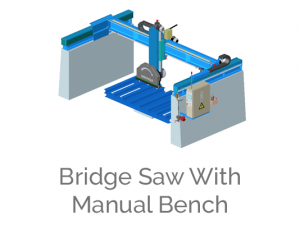

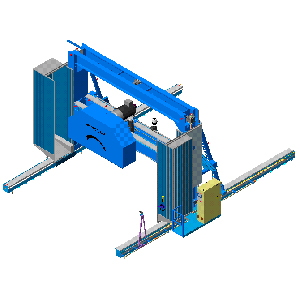

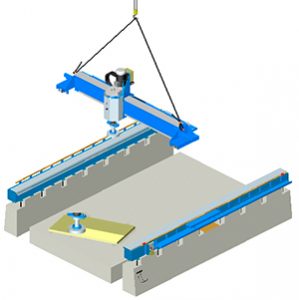

Portico Block Saw

Can also be adapted to other machines & if you intent please see any follow machine

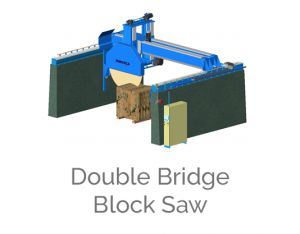

Double Bridge Block Saw

Can also be adapted to other machines & if you intent please see any follow machine

Concrete Pillars

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

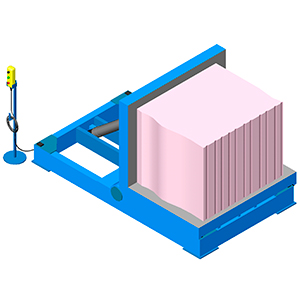

Block Tilt Bench

Can also be adapted to other machines & if you intent please see any follow machine

Polishing Equipment

Can also be adapted to other machines & if you intent please see any follow machine

Laser Focus to Alignment

Can also be adapted to other machines & if you intent please see any follow machine

More Displacement on Lateral Pillars

Can also be adapted to other machines & if you intent please see any follow machine

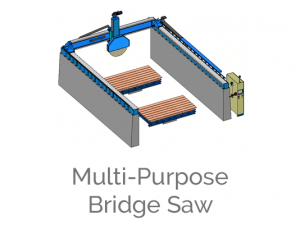

Works Machine

Allows The Use Of Several Tools

Receiving and machining file generated by cad cam system, the equipment produces the final product using several tools, also the displacement axes can be adopted to the type of work using our several bridge and cutting head models