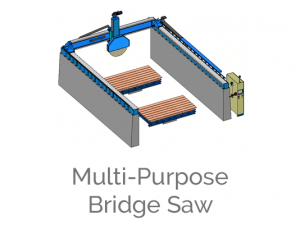

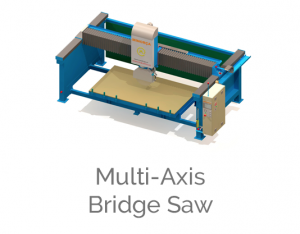

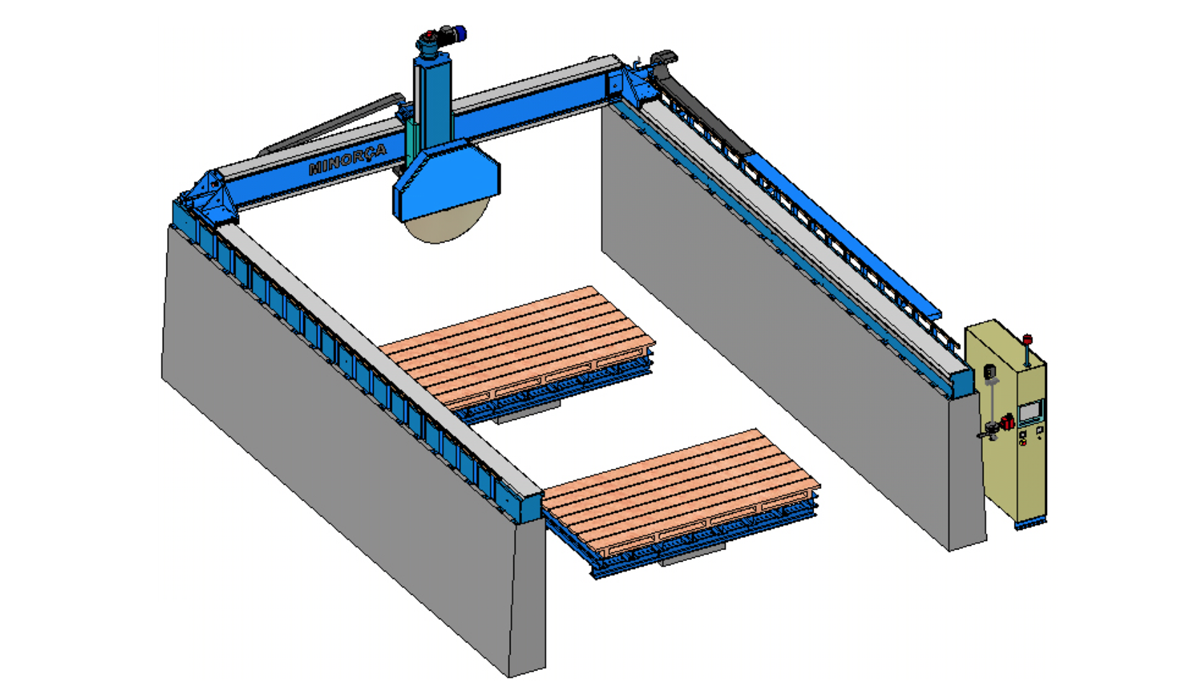

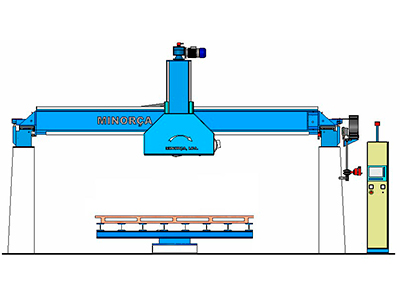

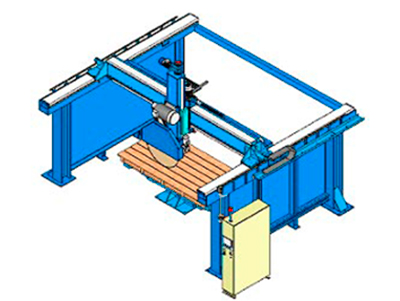

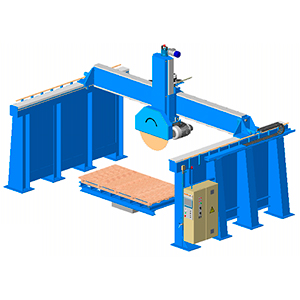

Multi-Purpose Bridge Saw

About

With a sturdy structure, it is the fastest in its segment, with hardly any dead time. It analyses the materials to be cut and combines several technologies.

Highly rentable equipment, several displacement options

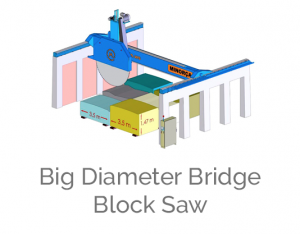

Bridge length between support walls 7 meters allows an cutting displacement of 4,85 meters on sandstone (in granite cutting by steps will be more) with 1,3 mt guard or more in vertical step’s process

Bridge length between support walls 5,3 meters allows an cutting displacement of 3,15 meters on sandstone (in granite cutting by steps will be more) with 1,3 mt guard or more in vertical step’s process

Vertical displacement above 1 meter allows several cutting steps and great polivalence on stone height

Vertical displacement of 0,3 meter allows the cutting process in sandstone by two steps

Programer by an touch screen allowing several menus since introduction of cutting dimensions until an proper draw to profile

Industrial console to introduce the several cutting dimensions and allow control the cutting velocity by check the saw strain or allows the cutting return in maximum velocity

Automatic rotation on bench allow stop on each degree (only with pc) , Manual rotation with blocked each 45 degres (8 possitions)

In all options the equipament are developed to an automatic cutting have to be defined the standart rotation of saw depending of stone.

Can also choose the tilt head, the inclination head until 45 degrees

Technical Features

ASSEMBLES VARIUS ACCESSORIES FOR MULTIPLE SERVICES

✓ Diameter of disc admitted – 1,300 millimeters (mm)

✓ Maximum cutting height – 510 mm (Minimum flange support 280 mm)

✓ Maximum vertical effective travel – Z axis = 600 mm ( or 900 mm or 1,200 mm)

✓ Cutting capacity – X axis = 3,520 mm; Y axis = 3,570 mm (for + optional)

✓ Power admitted on cutting motor 22 Kw ( 30 Hp) / 30 Kw ( 40 Hp ) / 55 kw ( 75 ) Hp

✓ Approximate minimum weight – 6,800 kilos (kg) to 8,300 Kg

✓ Maximum height required with automatic revolving table – 4,15 meters (mt) or 4,71 mt

✓ Inside distance between headwaters (for + optional 6,1 mt)

✓ Maximum cutting speed shift – 20 mt/minute

✓ Admitted peripheral speed of the cutting – 20 to 50 mt/sec

✓ Headwaters admitted – 4.5 – 5.5 -(concrete only 6 – 8.5 – 10) mt

Main Feature & Related Equipment

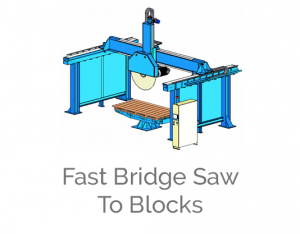

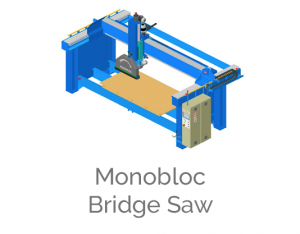

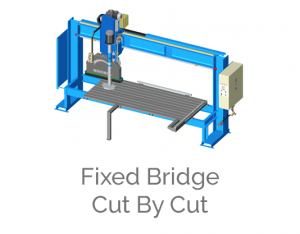

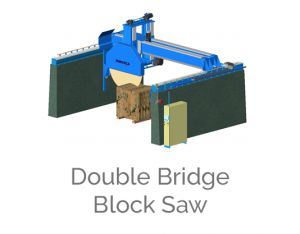

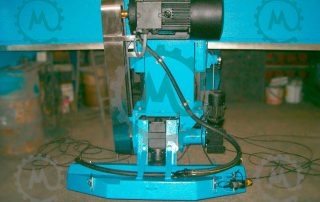

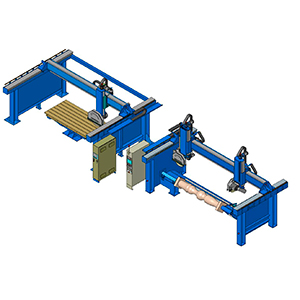

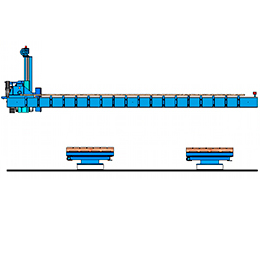

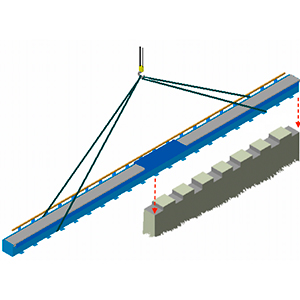

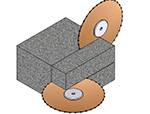

Block Cutter Saw on Mono Bridge Concept

That Models are able to cut blocks until 58 inch / 147cm with an low production cost.

Can also be adapted to other machines & if you intent please see any follow machine

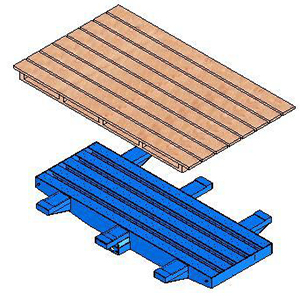

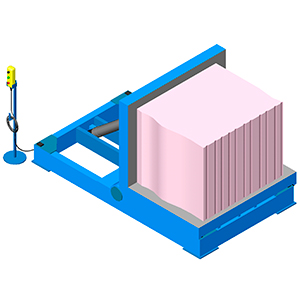

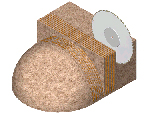

Rotary Bench

In automatic rotation allows every degree stop or continuous movement to profil, supports above 12tons; possibility to assemble manual indexation every 45 degree, in that mode will support above 6 tons.

Can also be adapted to other machines & if you intent please see any follow machine

Particular Cad Draw Programing

With the internal use of cad system the machines can cut surfaces without outsides recurses

Can also be adapted to other machines & if you intent please see any follow machine

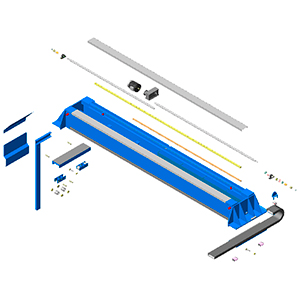

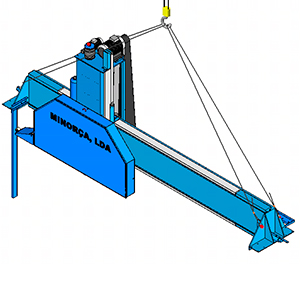

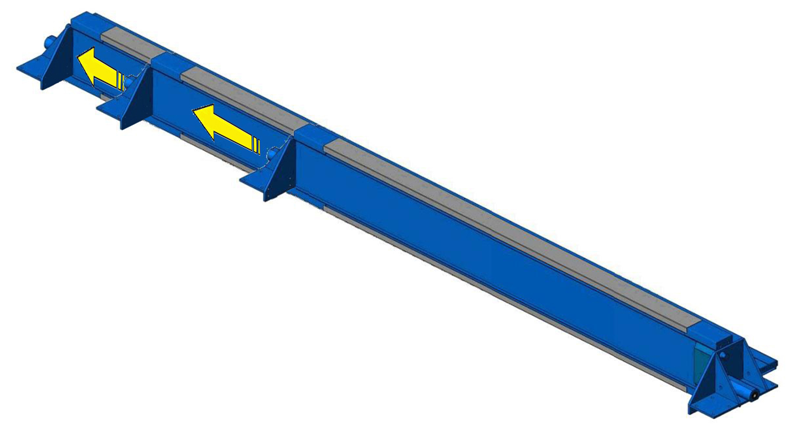

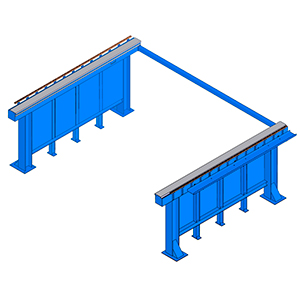

Several Length on Bridge

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

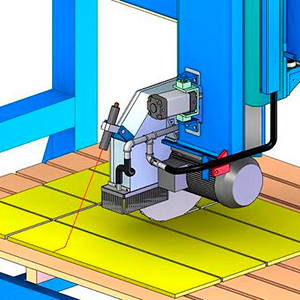

Horizontal Tilt

Horizontal cut position, allow automatic cycles and several disk diameter, with an rotating bench can make an fountain.

Can also be adapted to other machines & if you intent please see any follow machine

Increase Potential

Can also be adapted to other machines & if you intent please see any follow machine

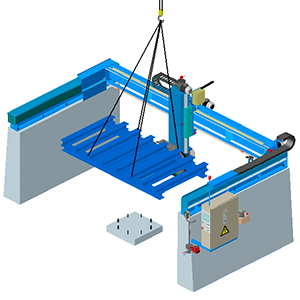

Concrete Pillars

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

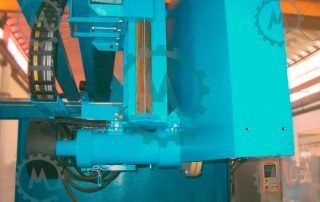

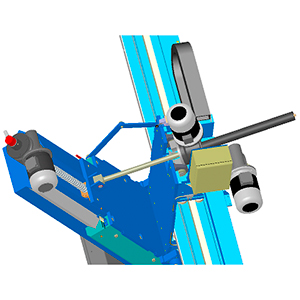

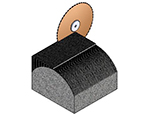

Inclination Head

Allows mitre joint cut since 1 until 45 degrees with several cutting cycles, no scar the stone

Can also be adapted to other machines & if you intent please see any follow machine

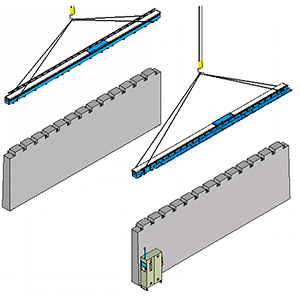

Lateral Pillars High Dimensioned

Can also be adapted to other machines & if you intent please see any follow machine

Metallic Pillars

Can also be adapted to other machines & if you intent please see any follow machine

Block Tilt Bench

Can also be adapted to other machines & if you intent please see any follow machine

Laser Focus to Alignment

Can also be adapted to other machines & if you intent please see any follow machine

More Displacement on Lateral Pillars

Can also be adapted to other machines & if you intent please see any follow machine

Video

Video

Works Machine

Multiple Axes Movement At Same Time

Can make profiles using several axes, depending of the control system it’s possible execute programs generated on cad cam system outside or in proper cad on control machine, the cutting parameters can be changed on machine, the final work quality it’s defined by quantity of cross cut

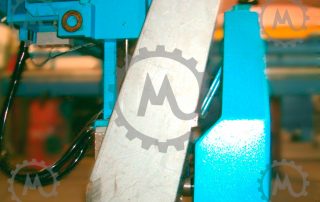

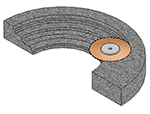

Saw Round Profile

By proper program can program the diameter, the rope quantity, the proper higher, the final work quality

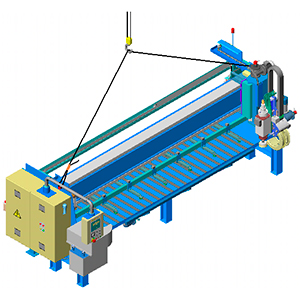

Water Treatment System

Allows the factory work with clean water, works in closed circuit the mud can be separated with an small humidity, theres several models adopted to all sizes of factory’s

Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can polishing the edges and put it in several shapes

Balustrade And Columns In Round Shape

Can do with proper cad program worked stones in several materials and also forms, like final quality, that one can be perfect, ready to polish

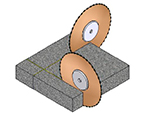

Profiling With Horizontal Saw

Can do that in several systems, the most fast and cheaper it’s coordinate the automatic rotation bench supporting above 12tons with the cutting head, can also work with the horizontal saw mixing several axes or milling the stone

Work Horizontal And Vertical

The saw can rotate and execute several cuttings on both angles

Execute 90 Degrees Cutting Angle

In automatic execution can program both cutting sides

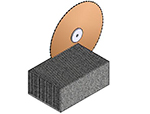

Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting

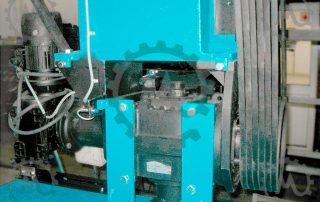

Tilting Saw For Angles Cutting

Theres two systems for angle cutting, the tilt head it’s the most cheaper, rentable and gives perfect finishing, the dual movement of axes can do the process also with the saw inclination axe

Surface Profiling

With one axe movement each time can produce forms by draw in a proper program on the machine