Tailor Made Equipments

About

Design and development of specific machines by order, with an proper project department we are able to provide tested solutions.

Technical Features

Technical Features

✓ Vertical displacement minimum – Z= 18,1/2 in / 47 cm (for more optional)

✓ Power of motors – start on 5,5Kw (7Hp) ; 15kw (20hp) / 30Amp. ; 22Kw (30Hp) ….

✓ Approximate workable weight – 88,000 lbs / 44 ton

✓ Cutting displacement velocity’s – start on 639 in / 16 mt/min.

✓ Maximum speed on displacement travel – 1,960 in / 50 mt /min.

✓ Minimum peripheral speed for cutting – 670 in / 17 mt/sec (set over pulies)

✓ Maximum peripheral speed for cutting – 2,750 in / 70 mt/sec (set up with inverter)

✓ Belt are defined until the maximum of 2×63 in / 2×1,6 mt ( 126 in / 3,2 mt )

✓ Belt lenght bench – until 394 in / 10 mt

Working Types

|

|

|

|---|---|---|

| Multiple Axes Movement At Same Time

Can make profiles using several axes, depending of the control system it’s possible execute programs generated on cad cam system outside or in proper cad on control machine, the cutting parameters can be changed on machine, the final work quality it’s defined by quantity of cross cut spacement |

Profiling With Horizontal Saw

Can do that in several systems, the most fast and cheaper it’s coordinate the automatic rotation bench supporting above 12tons with the cutting head, can also work with the horizontal saw mixing several axes or milling the stone |

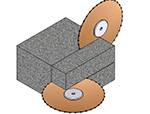

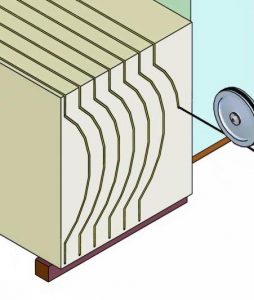

Cutting Execution by Lateral Development

This process can be executed in vertical as well in tilt position, to be a fast cutting can order only one axis cutting movement, much used on primary cleaning or in continued parts |

|

|

|

|---|---|---|

| Vertical and Tilt Cut Until 46 Grades On the ram can execute inclination since vertical at 0° until 46°, allowing the cutting process in several passages without step marks on the stone |

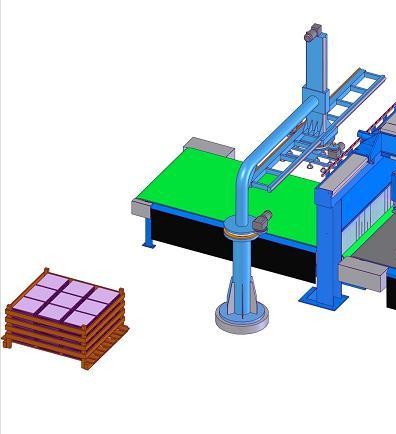

Palletization Process With several bench and robots can improve the shipping process |

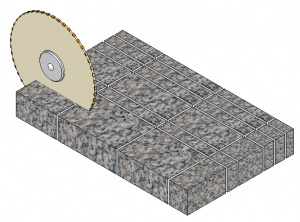

Execute 90 Degrees Cutting Angle

In automatic execution can program both cutting sides |

|

|

|

|---|---|---|

| Surface Profiling

With one axe movement each time can produce forms by draw in a proper program on the machine |

Tilting Saw For Angles Cutting

Theres two systems for angle cutting, the tilt head it’s the most cheaper, rentable and gives perfect finishing, the dual movement of axes can do the process also with the saw inclination axe |

Balustrade And Columns In Round Shape

Can do with proper cad program worked stones in several materials and also forms, like final quality, that one can be perfect, ready to polish |

|

|

|

|---|---|---|

| Rotative Bench Will provide easy alimentation also continuous machine work |

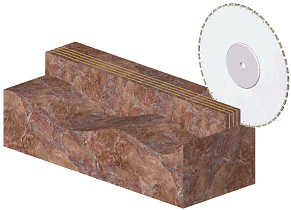

Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting |

Work Horizontal And Vertical

The saw can rotate and execute several cuttings on both angles |

|

|

|

|---|---|---|

| Multi-Axis Work Can profile in as the draw |

Saw Round Profile

By proper program can program the diameter, the rope quantity, the proper higher, the final work quality |

Cutting And Cleaning Profiling

After the cutting process the system allows an stone cleaning process with the slow displacement of saw by several movements leaving an final work without stairs |

|

|

|

|---|---|---|

| Carving or Hollow with Maximum Power With an stable ram and high power on saw can process the work in an fast time without the concern of low passages or the use of small tools |

Automatic Cutting Process in Several Steps also Directions With an proper menu can program the saw work |

Ability to Exchange the Saw Tools By the use of Iso tolls or head change can improve the process to input more cutting cycles |

|

|

|

|---|---|---|

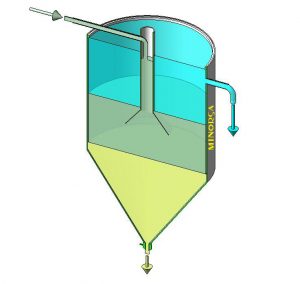

| Water Cleaning Process With the use of silo can improve the water treatment to allow it return to machines without lost time to remove the mud on it |

Movement on Total Oil Bath Ability Improve the time on movement parts and dispense the lubrication check up |

Additional Bench to Be Used On Times Between Main Execution

Improve production with an bench to be used as regular saw work, can be installed on rear or on side of the machine |

|

|

|

|---|---|---|

| Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can blasting the shapes |

Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can polishing the edges and put it in several shapes |

Primary Polishing Work

Starting the material operation with polishing the surface following the cutting process also it’s possible adopt on an proper finishing machine. |

|

|

|

|---|---|---|

| Carrossel Tool Change Provide the work with multi-tools, best to use on spindle |

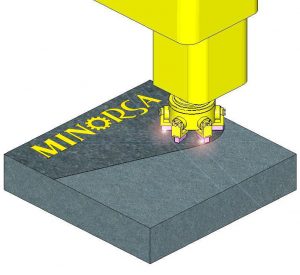

Profile Wire Saw With the use of multi axis work can shape the material by cable work |

Wire Saw cutting process With one or multiple cables will execute the slab cutting process, the must high height or length saw process |

|

|

|

|---|---|---|

| Head Change Ability Can set several heads on the same RAM allow multiple work on same equipment |

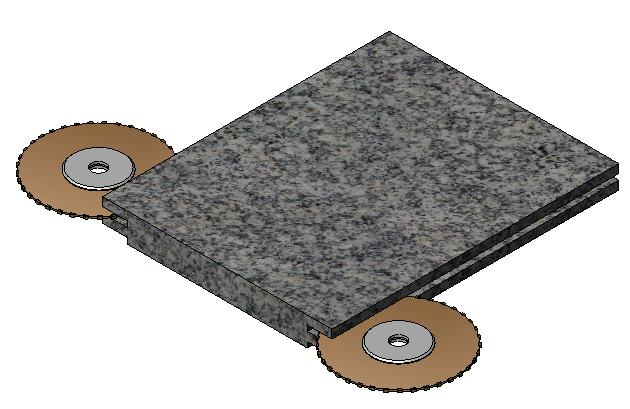

Lateral Double Side Cutting |

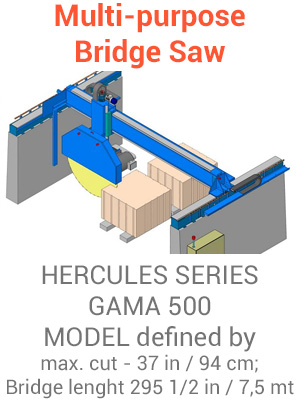

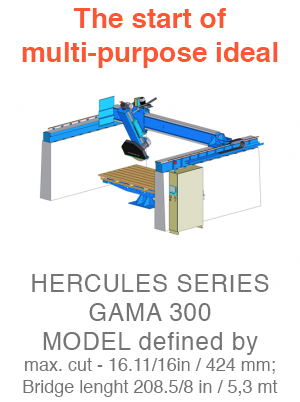

Stone Processing Equipments With Personalized Working Type

Several Working Heads Over Dual Ram

Can project an specific working way, by define the assembled heads and set an sequence to do the intend job.

We provide multiple heads, multiple travel Rams as the benchs choose.

The bridges provide are from Hercules Series over Pillars.

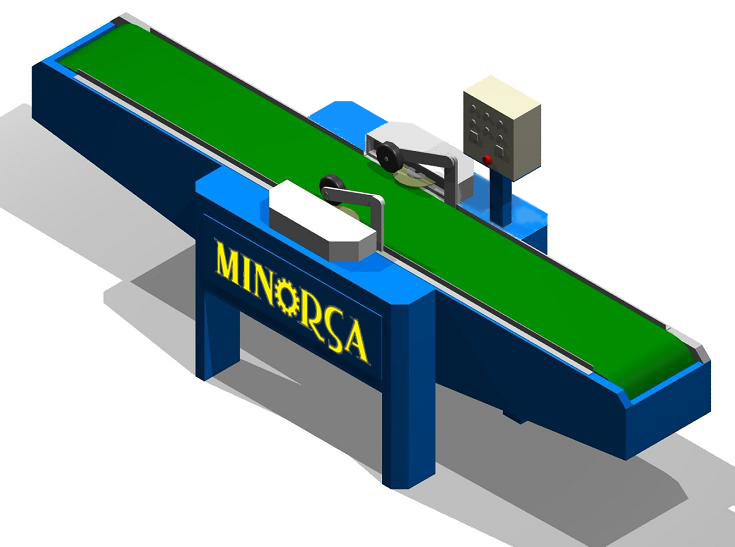

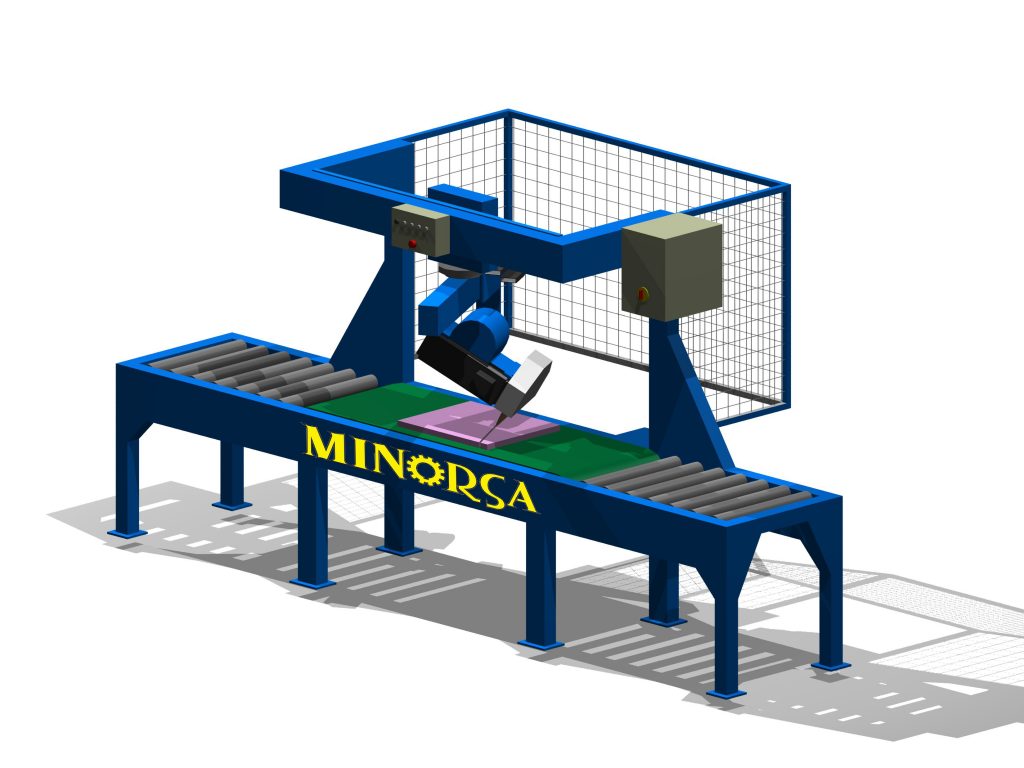

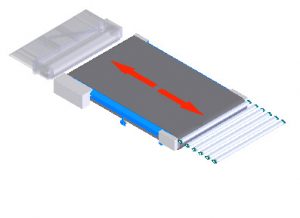

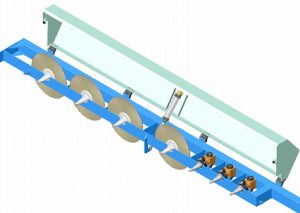

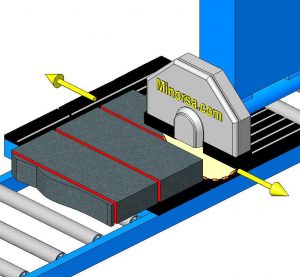

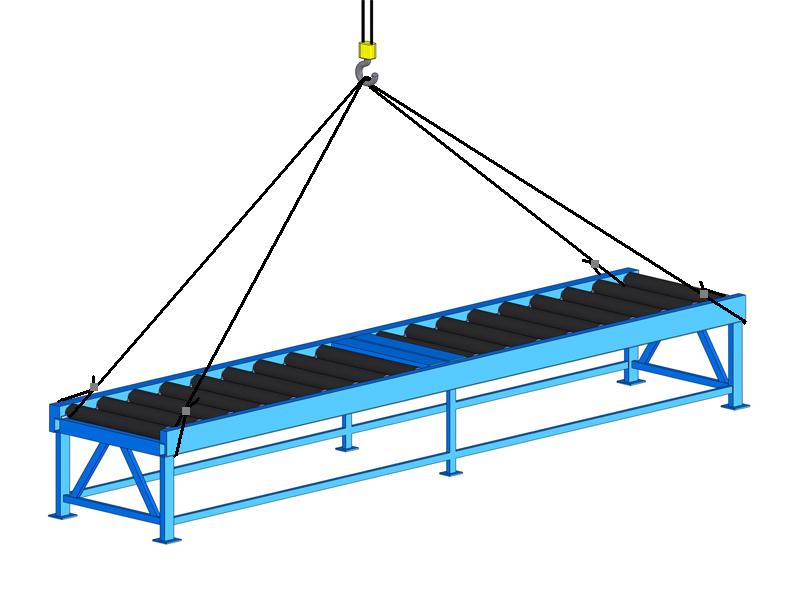

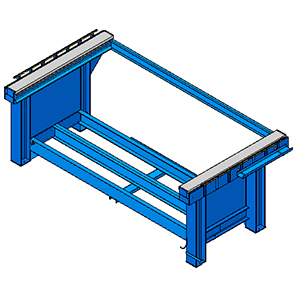

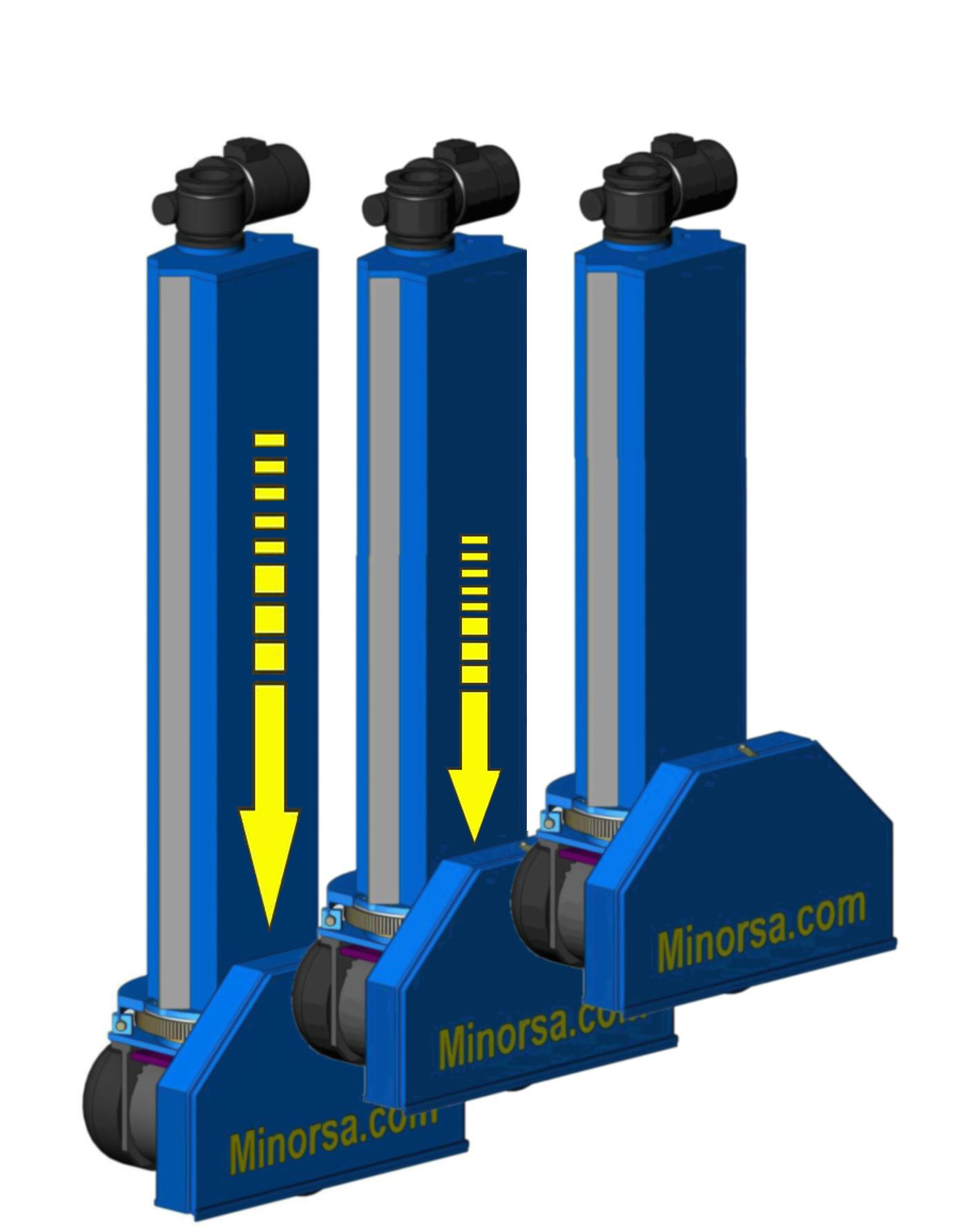

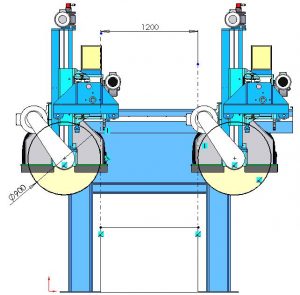

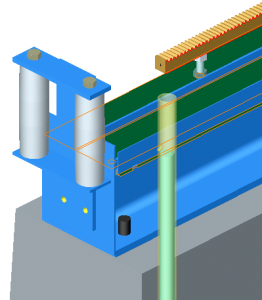

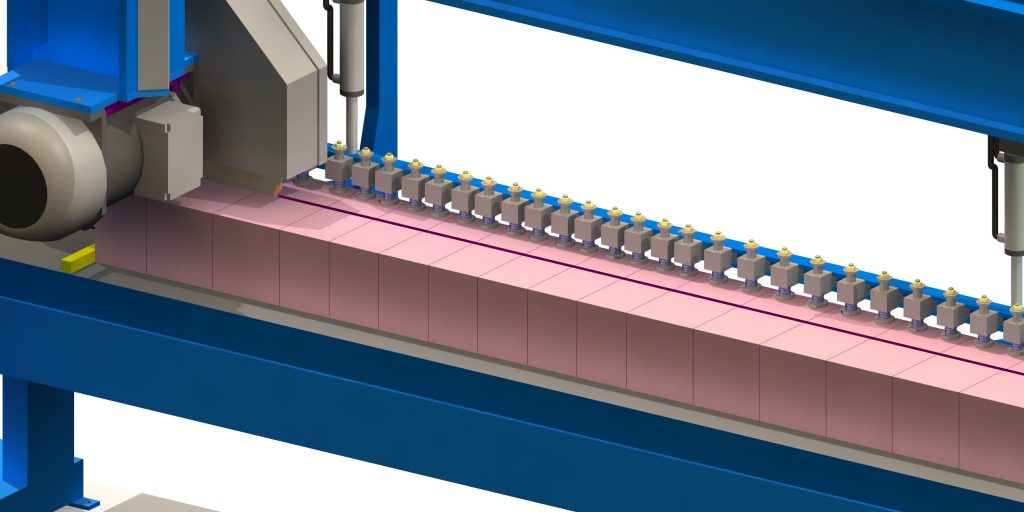

Roller system to cutting stripes

Provides the output of cut stone or can increase production downtime by cutting feed strips. The dimensions and the rollers weight capacity can be defined as you intend. 31,1/2 in. / 80 cm ; 63 in. / 1,6 mt. ; 78,1/2 in. / 2mt. and 86,1/2 in. / 2,2 mt. For example, to polish strips, you can order a vacuum autoloader that is inserted above the rollers, and after the process is complete, remove it and insert another stone.

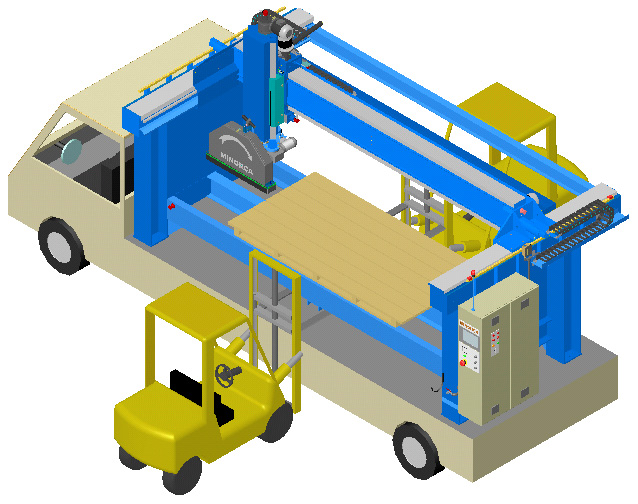

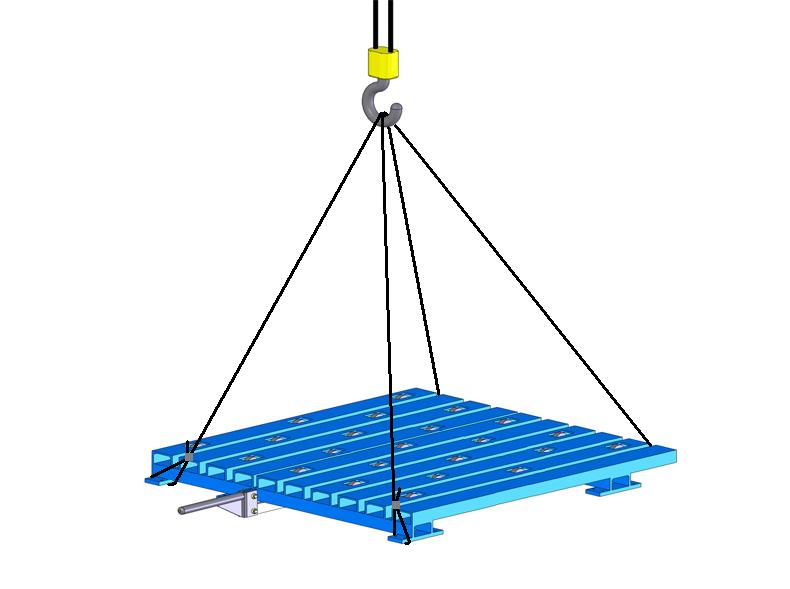

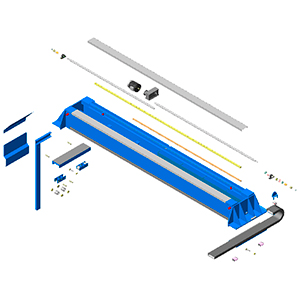

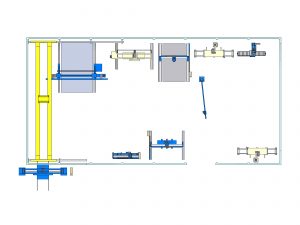

Rollers table for rear unload or cutting on the dead times

This workbench allows the equipment to work non-stop between major jobs, gaining moments of material change. It can be supported by a loading / unloading robot, can use a system to lift the material in the cutting process, and even has several pneumatic pistons to align the material with the saw. Usually it comes with engine rolls. The width starts on 31,1/2 in / 80cm and the standard length is 118 in / 3m plus on main body plus the exit rollers until pallets, those bodies can be made until 236in / 6m and assemble it together.

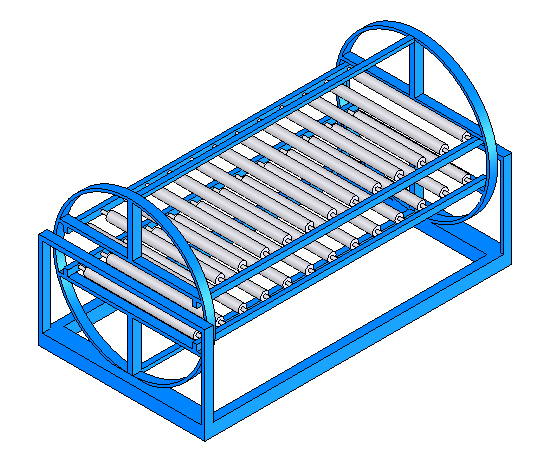

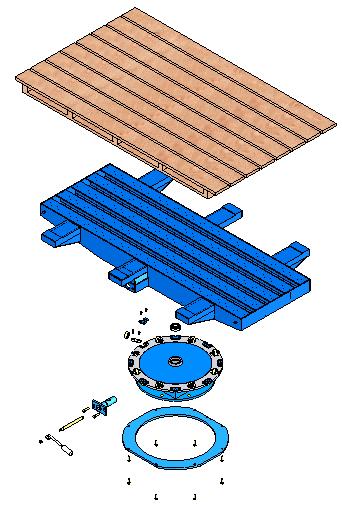

Rotate bench to mirror faces

tarts with 51 in / 1,3 mt slab passage to admit the block saw work, can rotate if intend the slab to provide the face to face cutting, electric movement with full inversion of material

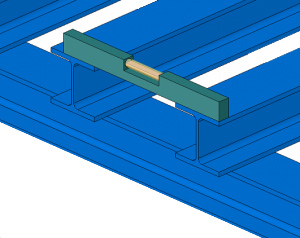

Slab movement system with gyratory balls

We have made several accessories to increase the potential of a specific job, such as a simple step-splitting stick or a U-frame for receiving multiple cubes or rustic bands, your idea will work.

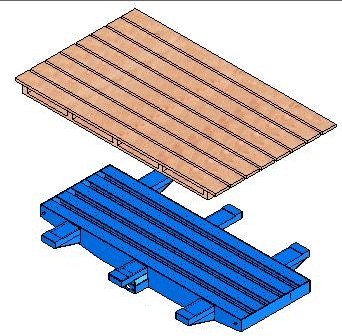

The workbench can be made with options to increase work progress through a separate attachment or a suitable workbench, as the ball system easily moves the slots or parts of it to the entire pine-wood bench.

Special order accessories, system in U shape to receive multi small stones.

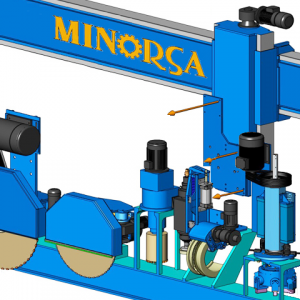

Robust Conception & Tested Heads Made the Easy Saw

Suitable for ALL heads IN ONE ram , can cut , polish , drill , edge faces and all more.

One Ram, one Bridge, one Beam , can cut , increase , mixing , adjust over specific frame.

Limited into the power and diameter, can use the vertical travel, fix and cut direct all in one.

The decision to use this Fix Series for specific operations will increase the potential and free the equipment installed, with adjust on proper tasks.

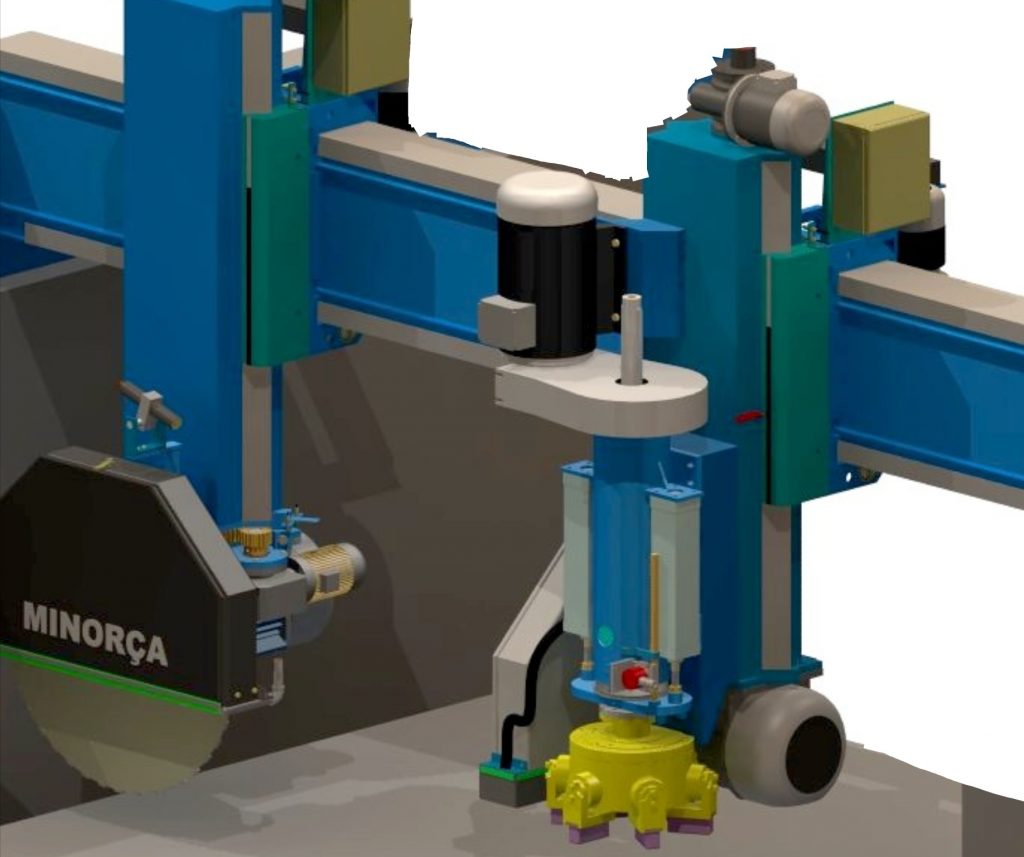

Milling system with independent or on multiple head

Tool admissible set by weight depending of the iso attach size. Present a minimum tool length defined by cutting car vertical displacement compensation and the engine power admitted at 8,000 rpm 5.5Kw /7.5Hp until Max. 22Kw / 30Hp. Working on with inverter control at regular 50Hz produces +100% of power and 6,000 rpm with continuous service.

The cutting process on tool working is by incremental spacing or by power and the tool can be change by linear cabinet or in carrousel for small tools

With this is possible adjust the tool above the flange with vertical movement and have nclination working system on cutting car

More vertical displacement and power on gamma 800 until 79 in / 2 mt

An independent working vertical motorization that can be applied in together with other principal engine on same cutting head. With this solution you didn’t need much power, because this male the cutting function with smaller tolls. The operation is conjugate between engines. After disc cutting process, the after disc cutting process engine down and is positioned to complement the scheduled. Also, can be mounted as main, to perform multi-service operations using the automatic tool change.

Horizontal disk

The horizontal disc can have an vertical positioning by electric motor

By the use of stop switch with an proper command move between them.

The start cutting deep is 5 in / 13 cm with disc 15,1/2 in / 40 cm

Can cut with saw until 43.1/4 in / 1.1 mt using the polished system

Or an high revolution engine power at 8,000 rpm 5.5 Kw / 7.5 Hp

until Max. 22 Kw / 30 Hp (in this case will allow more working tasks)

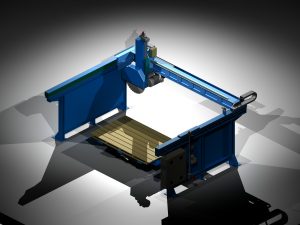

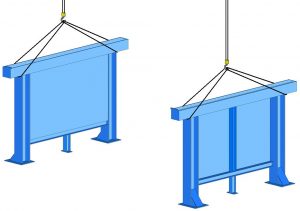

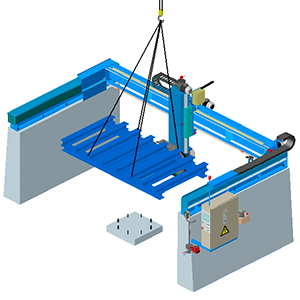

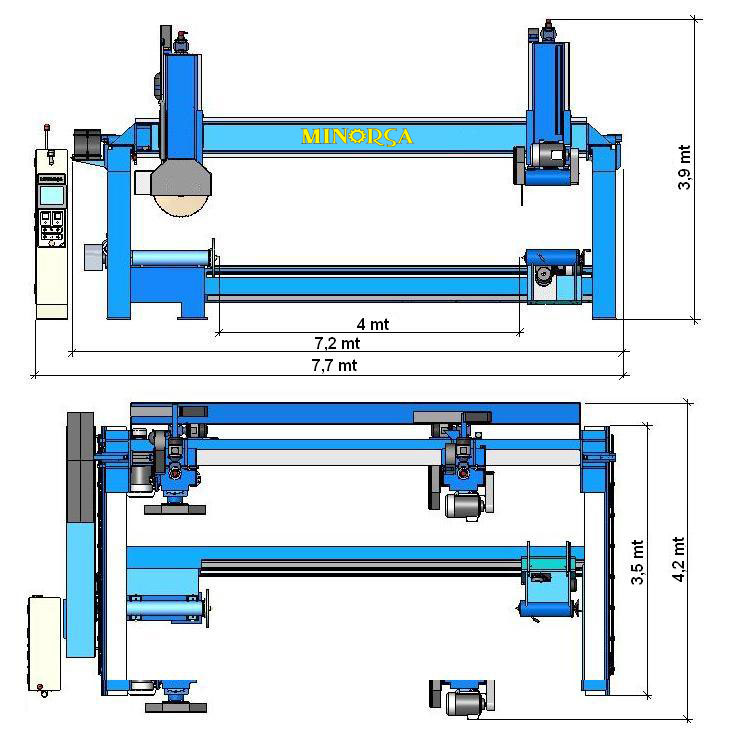

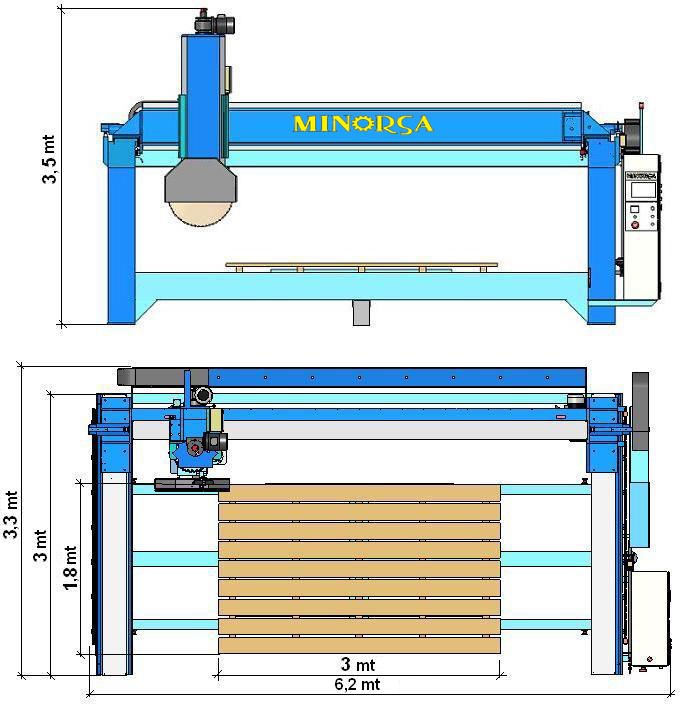

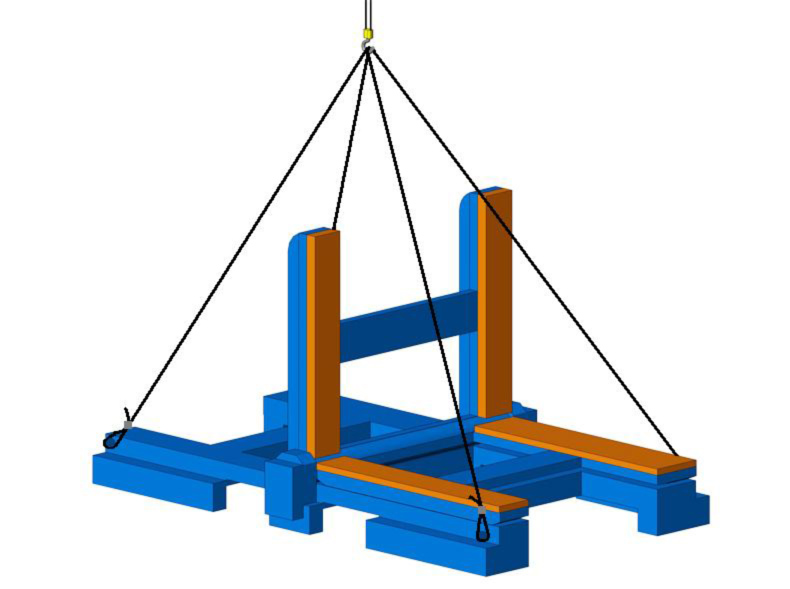

Can Assemble the Bridge Saw Over Metallic Structure

A good equipment support is primordial for a maximum yield on cutting process effort. We have two metal columns models, that can be mounted, depending of the bridge width, the ram height and the available power. Above structural value is suggested that the mounted be made on concrete. Since 1985 we have been assembling with 30 horsepower and 44 amperes effort. After 2002 we started to provide a 236 in / 6m cutting bridge for 55 ampere shear effort or consequent ram movement inversions.

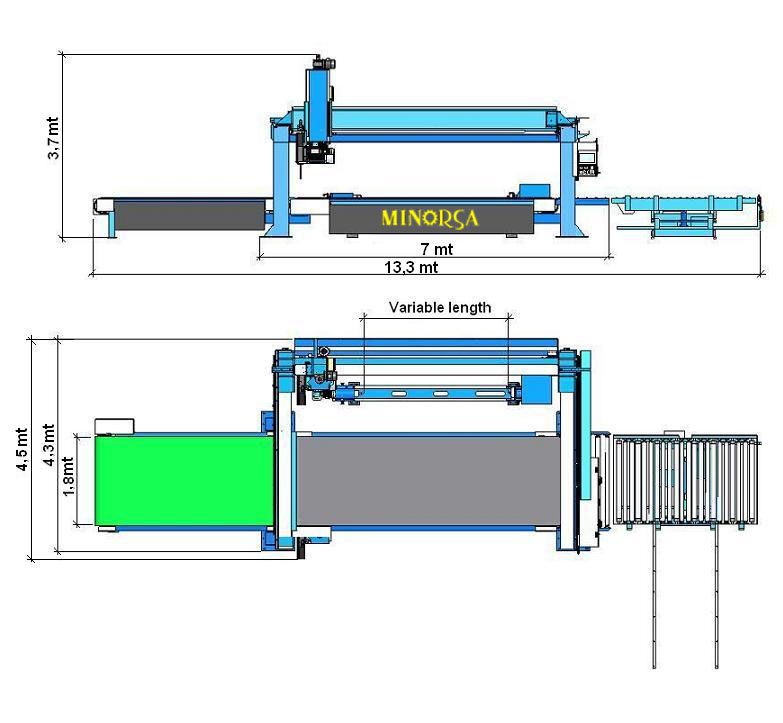

Monobloc Frame

Concept presented with an compact structure as a one-piece mono-block for easy installation and faster on-site equipment exchange, boasts thicker steel legs creates the monobloc, The main board separated from the machine to avoid vibrations and has easy access to programer screen. Maximize the cutting process with a precise and solid cut due to the use of the latest technology. It can be configured with one frame or multiple frames or only the continuation of lateral rails providing more bridge displacement for machines up to 43 inch ( in ) / 1,1 meters ( mt ) of the diameter and bridge length until 236 inch / 6 meters.

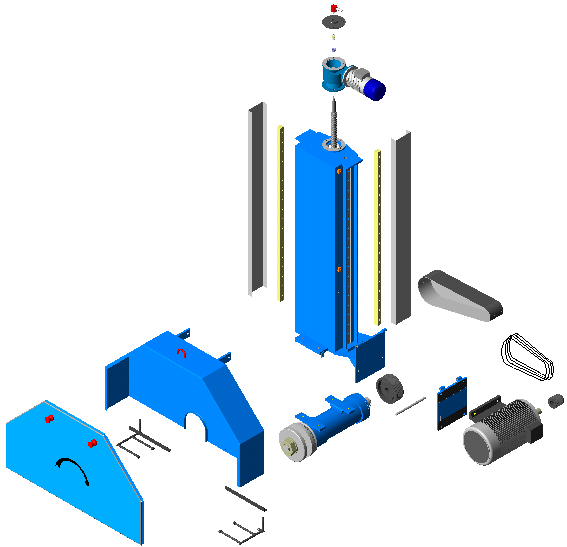

Metallic pillars

The metallic pillars are constructed as a single piece in order to increase the structural resistance and it are supported and fixed on a firm base, ensuring optimal performance. Regarding the surface treatment it is cleaned with steel shot, hot zinc plated and painted with three layers paint.

For operation with cutting operation, limited by maximum height and length.

You can mount accessories supports on the side, as material position markers or as a basis for laser focus. The position of the electric cabinet can be defined by the basic direction of water projection.

All the equipment works on the pillars. Outside, this support the remaining elements, as water valves, pressure controls, lubrication systems and cable carriers and water hoses. These pillars are suitable to use with double ram, because the effort movement follow the structure length. They are provided with a maximum length of 334,1/2 in / 8,5m and a total height of 98 inches / 2,5 meters.

Mixed Pillars

Can be suggested an only metallic pillar for situations of greater effort or as a way to assemble elements such, as workbenches.

One Set of Components, Assembled Over Same Beam Format Allow Create Multiple Easy And Profitable Working Solutions.

The concept of the Fix series is to share components pre mades. We have several displacement over beams, robustness are tested over parts.

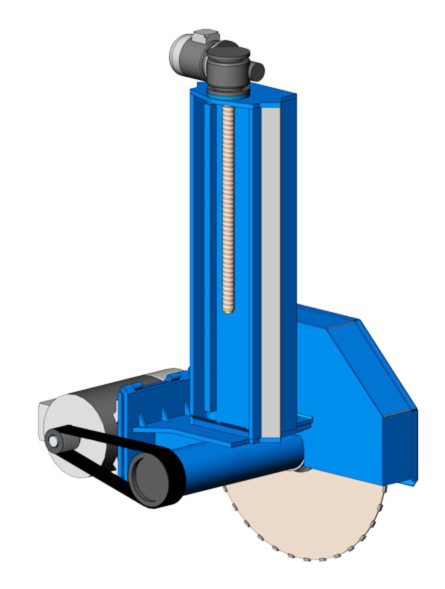

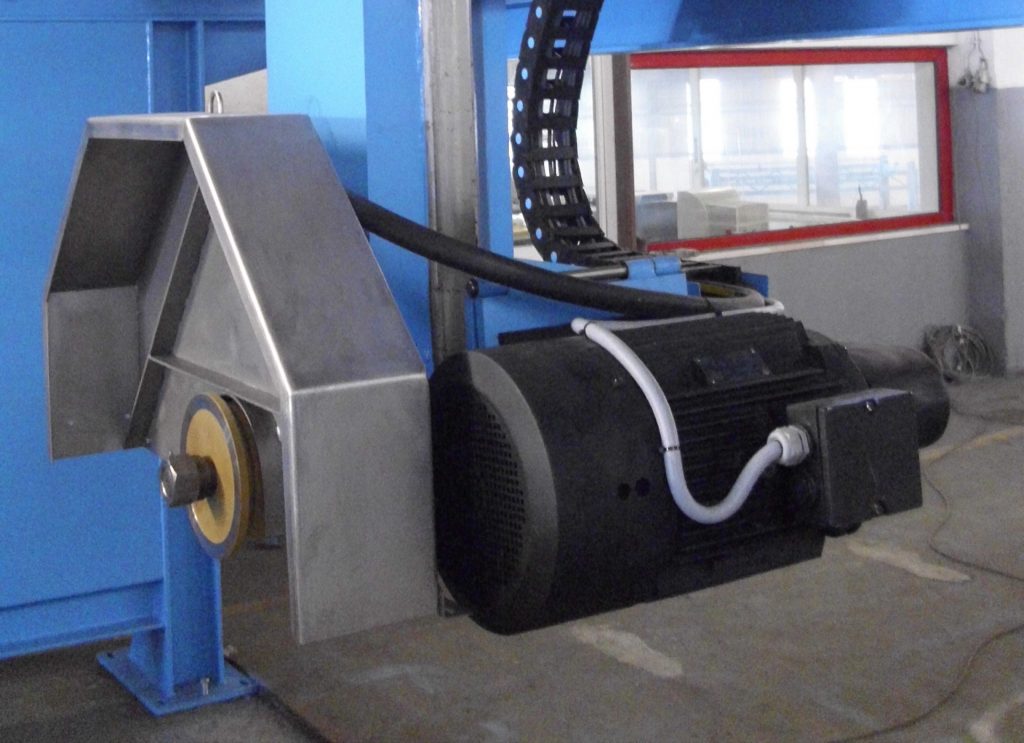

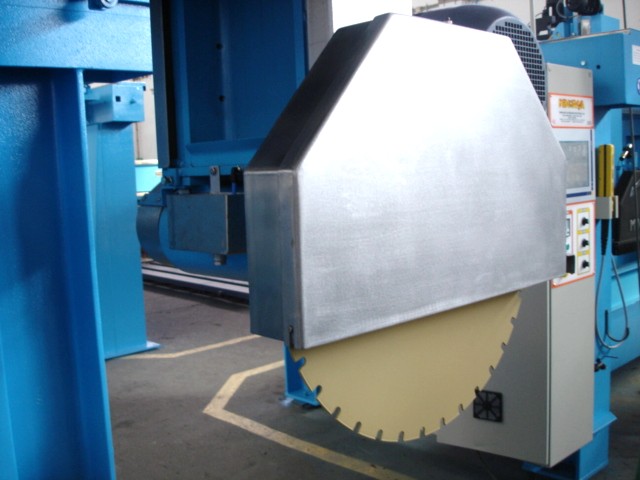

Direct power on cutting saw

This cutting power solution provides maximum saw power. Limited to diameters until 29,1/2 in / 72,5 cm, we assure the best optimization of cutting process. The head can be supplied with various options as rotation, fixed or adopting two heads on same beam. The mixing of parts depends of enfort as well power.

We will understand yours needs and present an solution based on examples here presented and on our experience in the cuppling the pasts.

Cutting engine directly connected to the disc, so that all available speed and torque can be used without loss of power, thus improving the cutting power.

For low speed cutting, we mounted an inverter with one reduction levels of pulleys to increase torque.

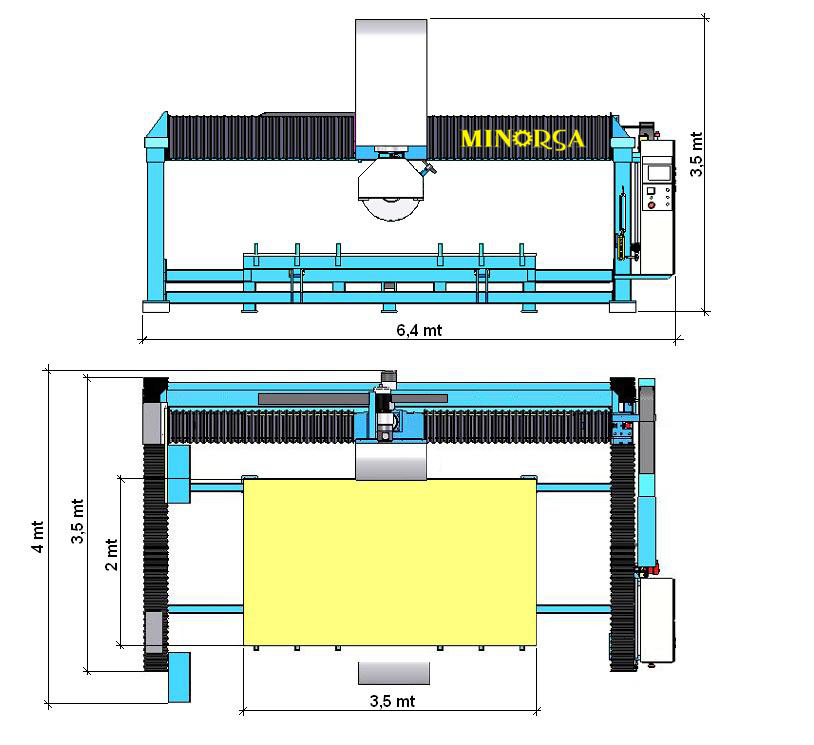

Pulley transmission to allow the best power on saw

-We mount the engine on the left or right side depending on the water projection. With the correct pulley size, power is supplied to the saw at most. With the V-system in vertical displacement, the ram is more adherent, allowing perfect alignment. The ram system is always used on discs over 35.1 / 2in / 900mm.

Several displacements on vertical ram

Displacement System Ideal

16 in / 400 mm V one passage cutting with high power

27,1/2 in / 700 mm V or Linear multiple heads , inclination head

35,1/2 in / 900 mm V or Linear diameter range of motion , inclination head

Fast and Easy

100% monoframe

Level, make the wire connection, water on, take final tests and work specific training, and it’s ready to work 24/7.

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Common Parts

The FIX SERIES adopts the principle of using common parts by changing their components on same metods an structures, what we have here is the same support displacement car used in different ways to provide an low cust solution.

Standard Parts In:

Working tables

The intention is to indicate that the parts and components produced starting in a project were subjected to intensive tests. In the FIX SERIES they are used according to a manufacturing plan, from individual design of the pieces to their join assembly.

With an accessory or component that will be combined with other to get a reliable and cost-effective equipment, easy to operate and maintain, and usable to its full capacity either in production or in its profit.

Cutting heads

All the components are designed to be interchangeable between the FIX SERIES.

Is this the concept that we intend to present: developed, tested, interchangeable, capable of receiving various upgrades, potential for expansion either in power, and that allowing the accessory exchange.

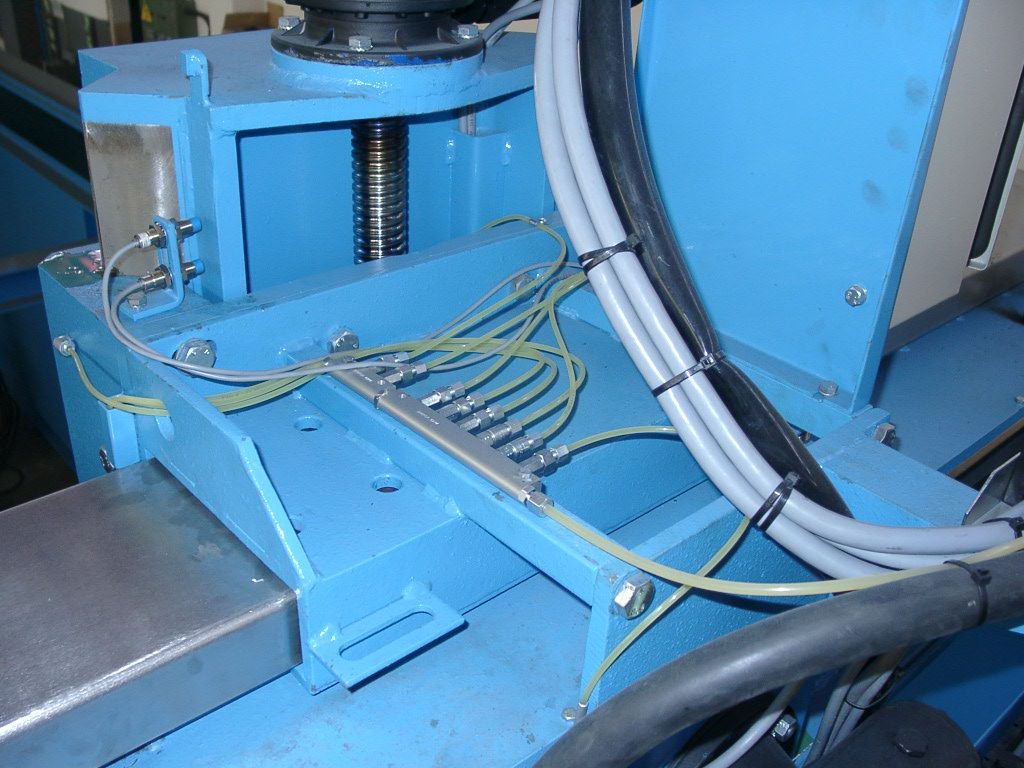

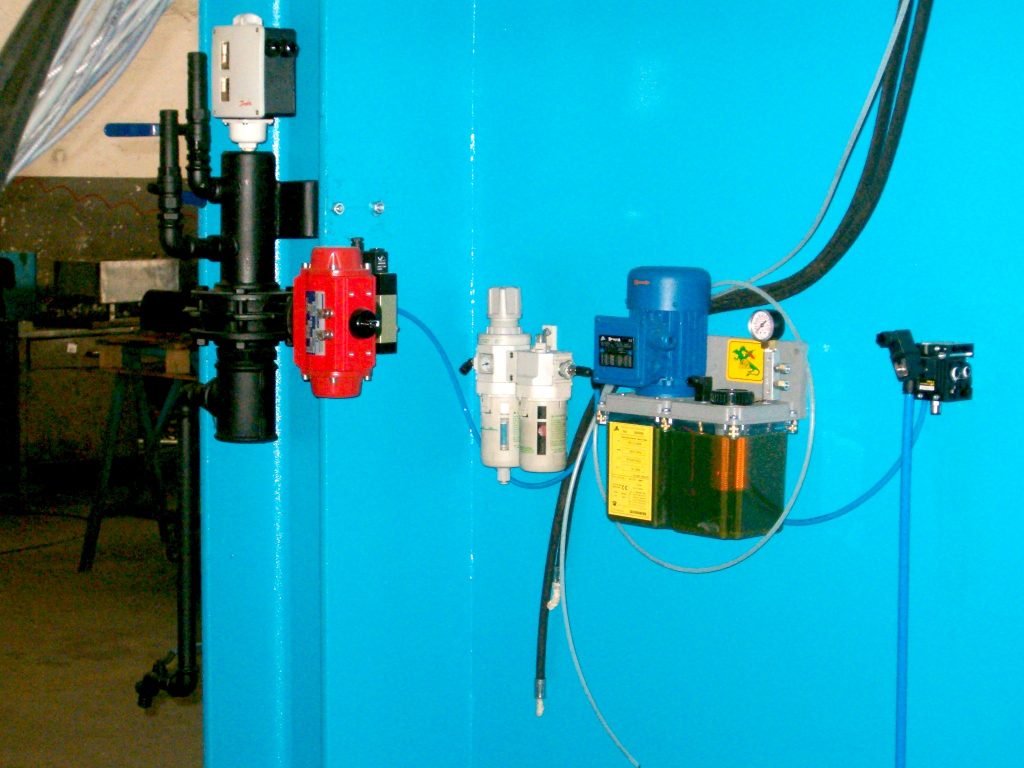

Automatic lubrication on all displacement points: water on/off automatic valve

The auxiliary components are also selected for their good operation and easy maintenance, and the security systems are assembled for easy identification and protection from events.

Power failure recovery (position and status memory) to continue working automatically, saving time and materials to be cut;

Automatic cut-off stop protection, if material gets stuck, slow down or at the end of the program;

Automatic axle stop/protection in case of mechanical anomalies during operation;

Displacement stops cease working to avoid programming or operation errors;

The equipment stops when opening the electrical panel;

Low voltage manual control switch to protect operator;

Electric protection by using magneto thermal switches (without fuses);

Regulated power supply, protecting low voltage circuits against power surges;

The equipment stops after encoder pulse count failure or contactor obstruction;

Automatic lubrication system with times, which allows keep the equipment lubricated at all its constant movement points, without the need operator interventions with oil pressure switch in case of pressure loss in the circuit.

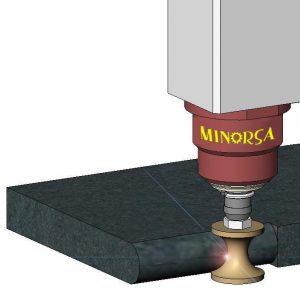

Laser with continuous focus

Accessories with laser focus, allows the use of laser for better alignment of the initial positioning on the pieces to be cut. One of its features is the individual variable speed transmission, which allows for more precise adjustment of speed and position. This also has water shut-off valves fitted as standard unless otherwise requested.

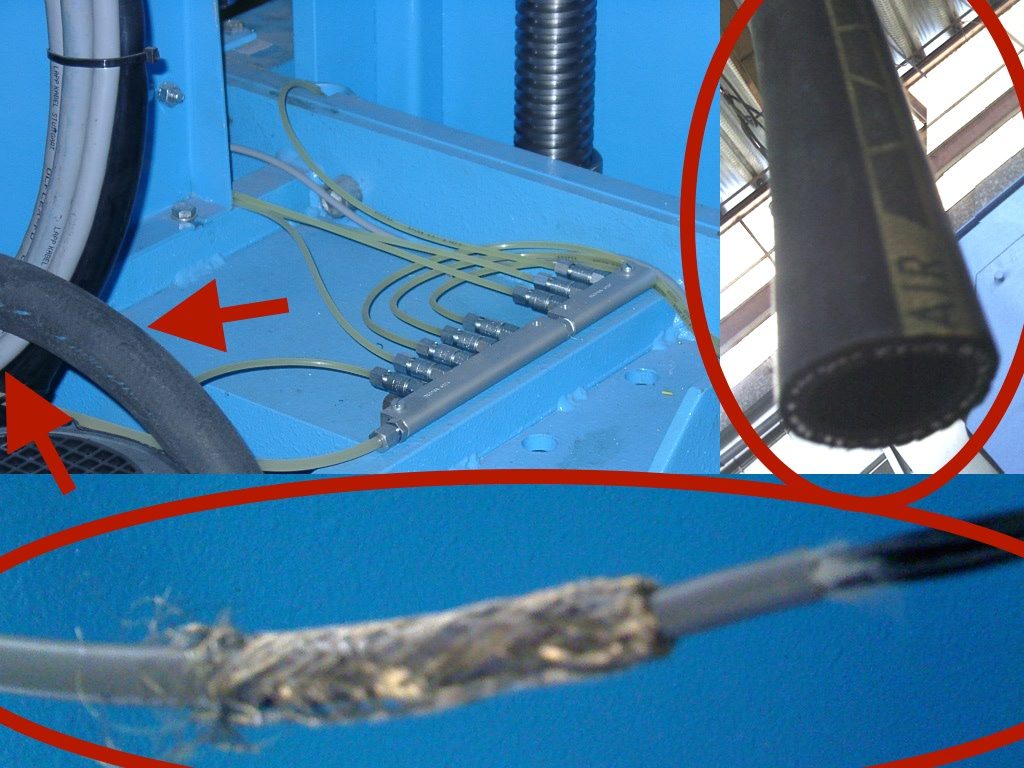

Water pressure system control/protection on cables by cover mesh/pressure water pipes

Special electric cables with mesh sheathed, moved through the cable supporting rails. Measure Encoder component with braided wire mesh cables (counting system) to protect against power surges. The base installation also has inner lined water cables consisting of a mesh reinforced rubber hose inside. Shields and rails for collecting the oil coming from lubrication of material used for cutting. Water pressure switch to control cooling and washing of the saw. (Placed on top of pillar for greater accuracy).

Electric board projected with CE rools

Electrical panel ventilation system with temperature control. Software under development to facilitate data entry and reading, based on operator feedback and questions. Mains fault detection system.

Standard components of well reputed brands

Using reputable brand components and applying operating concepts ensures full operation in the future.

Multiple benefits and aid capabilities:

Sets cutting at middle

Can order several accessories to acoplate or bult-in as Frame support to inclinate with proper angle cutting piece by piece

Special order accessories, system in U shape to receive multi small stones.

Foot Print

Equipment Ready to Work Over an Integral Chassis

The Standard Production Allows Increase Several Components in All Gammas

Radio control gives the operator more freedom of movement.

The flange is made to ensure that the pulleys system doesn’t reach the material.

The main screw is stainless steel.

An water projection fork in zinc treated iron is made to be removable

Allowing an easy change of the disc

Surface treatment is always done with a hot zinc projection base.

Metal side pillars are made in one piece.

An extension can be mounted to get close to the bench and provide smaller diameter discs.

This makes the equipment in the assembly taller to support larger diameters.

Water shields upon displacement of the rails may be provided to prevent the projection to the other side.

A support can be made to position the laser line above the cutting disc.

Centralized lubrication provided on plastic pipes with central connection elements.

Mesh reinforced rubber water hose, steel wire braided cables.

Water pressure switch to control cooling; Oil pressure switch in lubrication system, and air filters.

Junction box for axis cables and quick water connection.

Flexible cables moved by the cable support rails.

Flag crane for working with suction cups or tweezers.

You can set the time on arm, capacity, electric or manual movement.

Pine wood bench to work with forklift or allow the small diameters work.

Size: 5,1/2in / 14cm high and 118in / 3m by 70,3/4in / 1,8m

Special order accessories, system in U shape to receive multi small stones.

Metallic frame with pine wood over to work by forklift and crane.

Piping Drilling Equipment

About

This head can be used to core drill / Hollow drill on high diameters

– The vertical length is defined as intend

– The power can be defined as the intend

– can work with diamond pads or with granet method

– To can make a great drilling it’s needed to have low rotation with a lot of power. This specific head makes its hole cycles on automatic mode, being able to work after hours, changing the hole, and controlling the effort on the tool. It is the suitable to make big diameters holes, because its extreme dimension support underpinned on positioning bridge

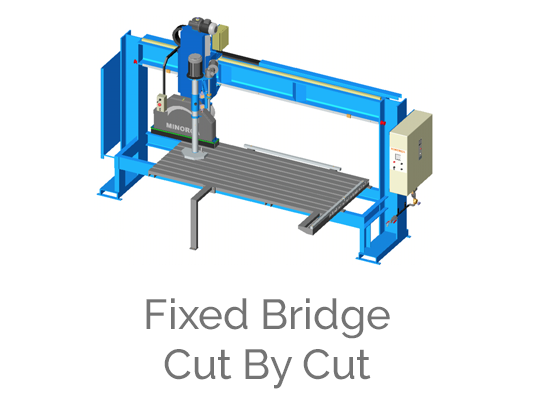

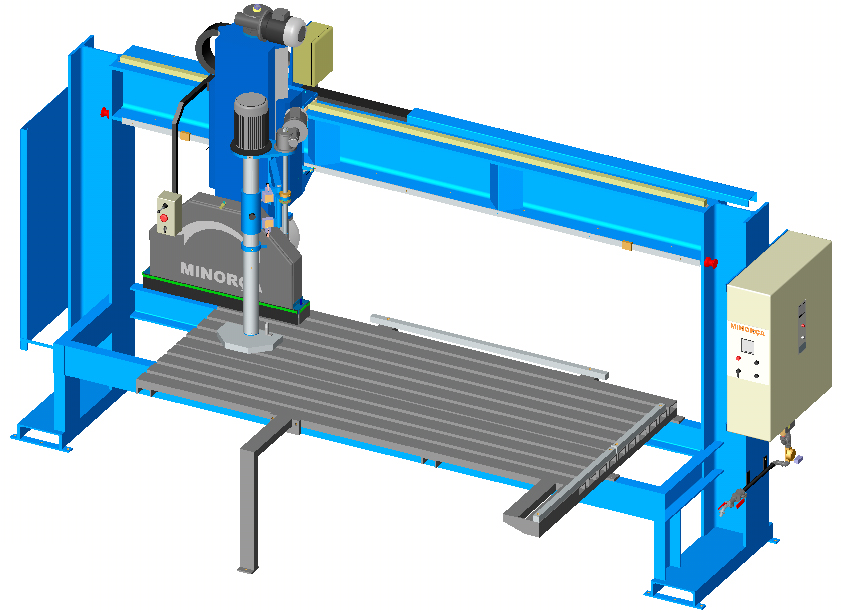

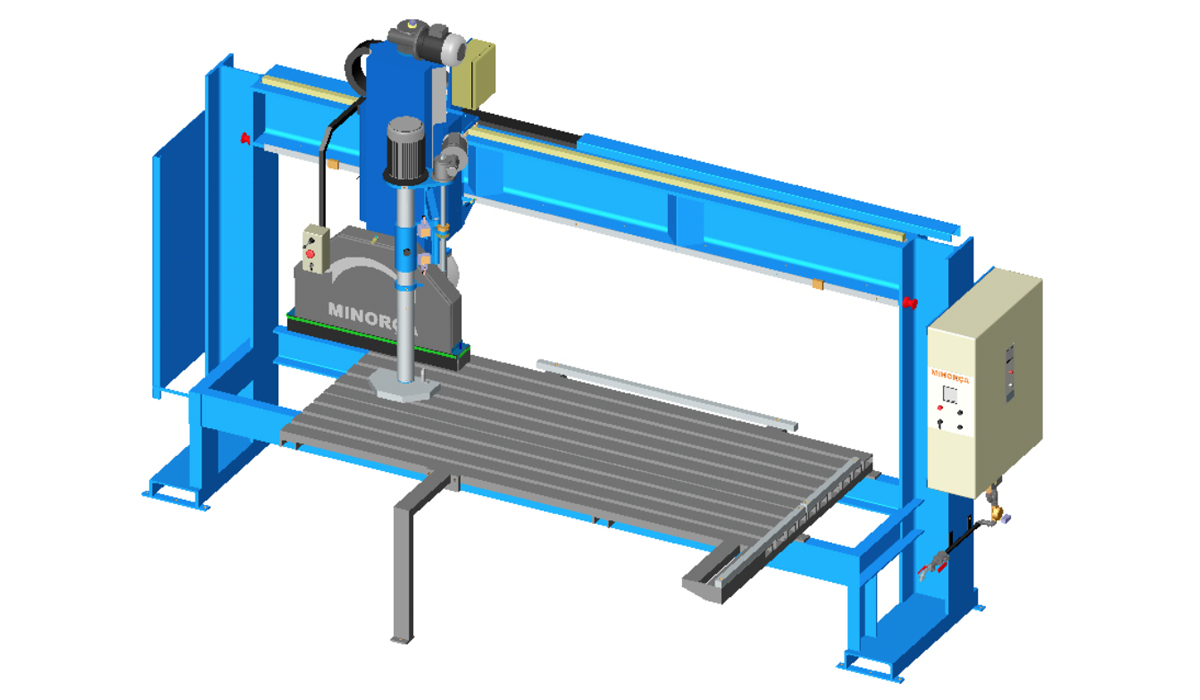

Fixed Bridge Cut By Cut

About

For sawing without any measures and to carry out specific tasks. Use of a worktable according to the work needed, automatic in the single cut cycle.

Technical Features

✓ Diameter of the disc permissible – 450 mm to 1,000 mm

✓ Maximum cutting height – 375 mm (Falange 250 mm)

✓ Vertical displacement minimum – Z= 470mm (for more optional)

✓ Cutting capacity – X= 3,500mm on 600mm diameter (for more optional)

✓ Power of main motor – 15kw (20hp) / 30Amp. ; 22Kw (30Hp)

✓ Approximate minimum weight – 1,800Kg

✓ Maximum height required for operation – 2,6 meters x 5,5 meters

✓ Cutting displacement velocity’s – 16 mt/min.

✓ Maximum speed delocamento cut –

✓ minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

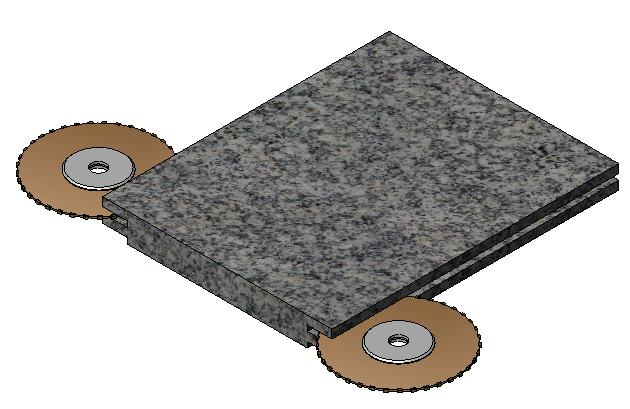

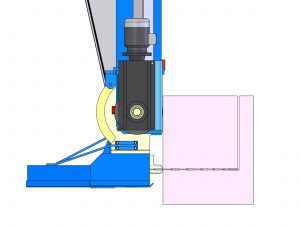

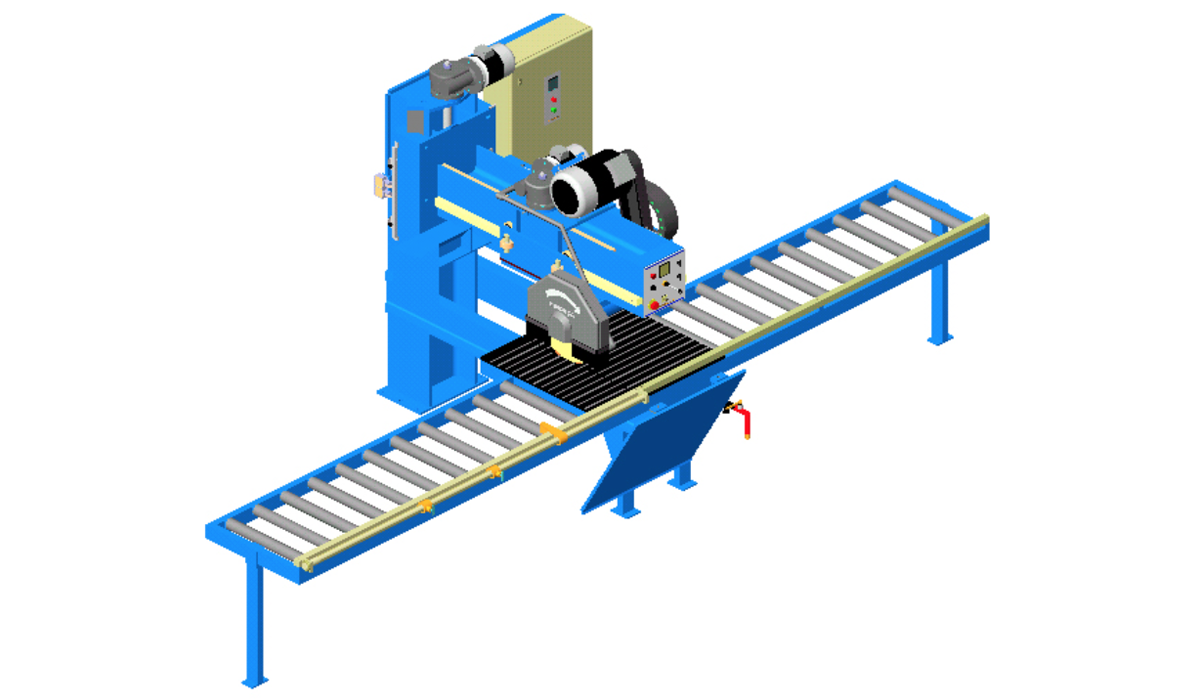

Cutting Corner Saw

About

Frequently used to support automatic cutting equipment, freeing it from time-consuming tasks.

Timing control with speed adjustment, deceleration ramps at the end of the cut, and disc return button to finish a cut without it reaching the travel stop.

Successive z-axis cuts to use with hard materials, and vertical position setting to start or end the cut.

The cutting table is removable, which helps during transportation and it can be made with a custom roller width.

The motor can be operated by an inverter in order to optimize cut capability by changing the peripheral speed.

Technical Features

✓ Diameter of the disc permissible – 350mm to 450mm (725mm)

✓ Maximum cutting height – 155mm (Falange 140mm)

✓ Vertical displacement minimum – Z= 250mm (for more optional)

✓ Cutting capacity – Y= 800mm (for more optional)

✓ Power of main motor – 7,5kw (10hp) / 15,5Amp. ; 22Kw (30Hp)

✓ Approximate minimum weight – 800Kg

✓ Maximum height required for operation – 1.7 meters x 4 meters large

✓ Cutting displacement velocity’s – 16 mt/min.

✓ minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

Lateral Double Side Cutting