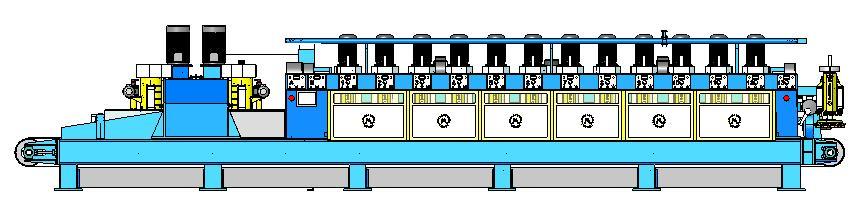

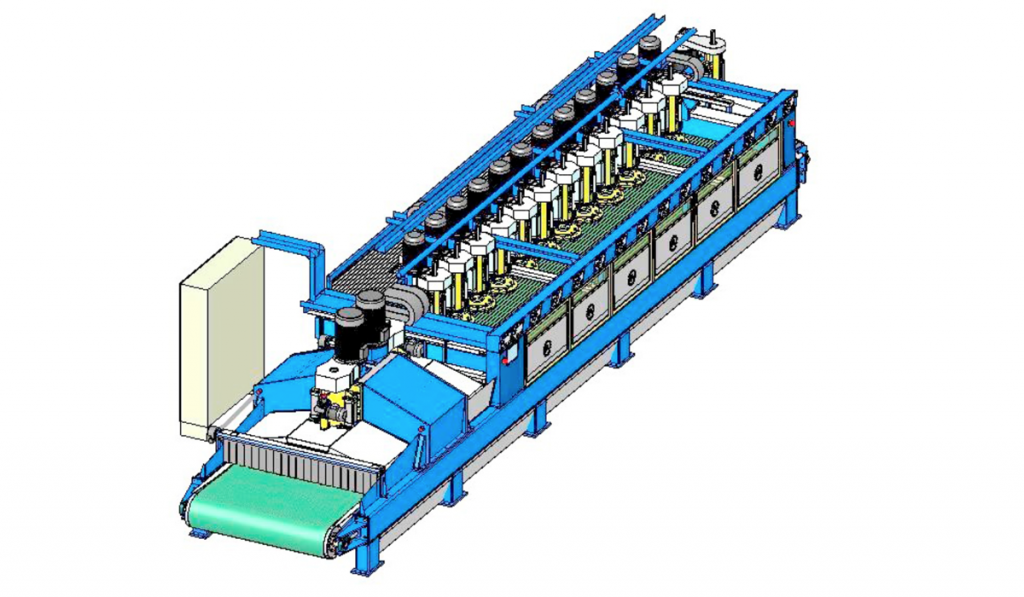

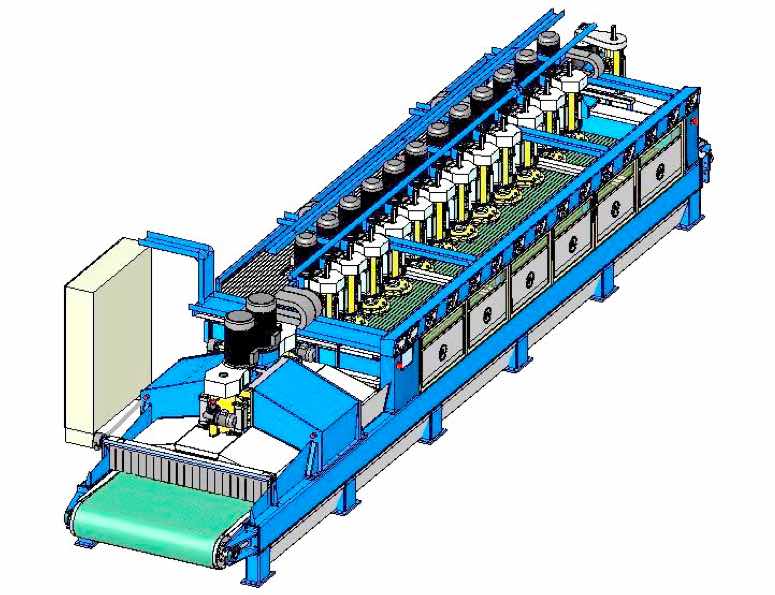

Multi-Head Polishing With Alimentation

About

MARBLE SLAB POLISHING MACHINE , Can be fully disassembled for easy transportation in containers ; Fully rectified on the worktable and lateral sides

The milling is done all at once in our ten meter long capacity machine ; We guarantee full alignment. ; above 32,5 tons

Technical Features

Marble & Limestone Granite Standard engine power / nr.of heads

10 Kw / 12+2+1 15 Kw / 12 + 4

Tikness capacity 100 mm 100 mm (optional until 140 mm)

Diameter diamond plate Ø 490 mm Ø 450 mm

Diameter polishing disk Ø 1.100 mm (37kw x2) none

Weight 32.600 Kg 28.400 Kg

Liters per minute (L/m) 500 700

Total installed power 240 Kw 240 Kw

MAIN FEATURE

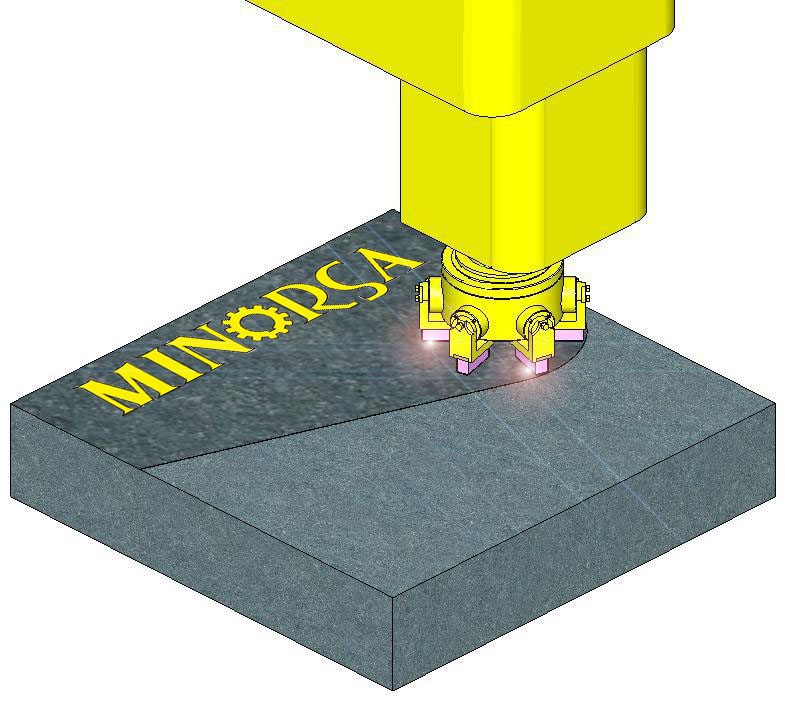

Cnc machined

The worktable is reinforced for a stable operation

After the anti-corrosion treatment with zinc, all the elements receive a primary paint and a final layer of textured paint (paint with particles to improve protection)

All equipment elements are fully tested before the final assembly

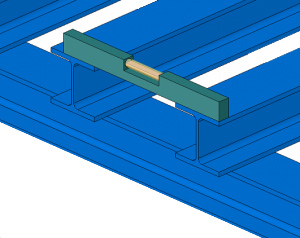

The work table has several grooves so that the conveyer belt can operate with the less possible friction.

The structure is steel blasted and the surface is hot-zinc coated

Its oversized dimensions allows for an excellent polishing power with high-end quality

Can be assembled according to the material you wish to work

HISTORY: THIS MODEL WITH BIG DIAMOND HEADS START IN 2012 AND WITH 2 PARTS TABLE ; WE DEVELEPMENT THE DISPLACEMENT BRIDGE ON LINEAR GIDES

SINCE 1993 AND POLISHING MACHINES SINCE 1999

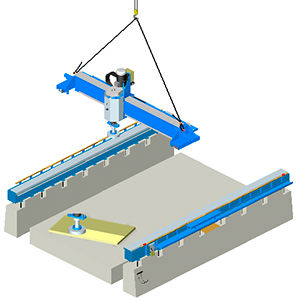

Calibrate and Polishing Over Mono Bridge

Decide maximum travel capacity

(all adopted features are common across all ranges)

Working Types

|

|

|

|---|---|---|

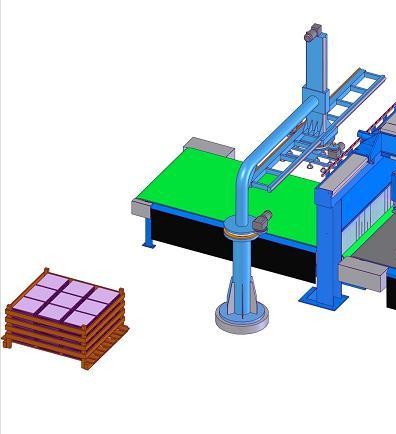

| Palletization Process With several bench and robots can improve the shipping process |

Primary Polishing Work

Starting the material operation with polishing the surface following the cutting process also it’s possible adopt on an proper finishing machine. |

Movement on Total Oil Bath Ability Improve the time on movement parts and dispense the lubrication check up |

|

||

|---|---|---|

| Rotative Bench Will provide easy alimentation also continuous machine work |

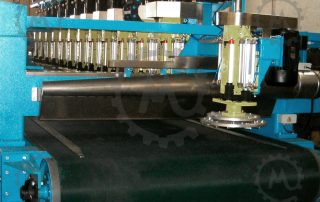

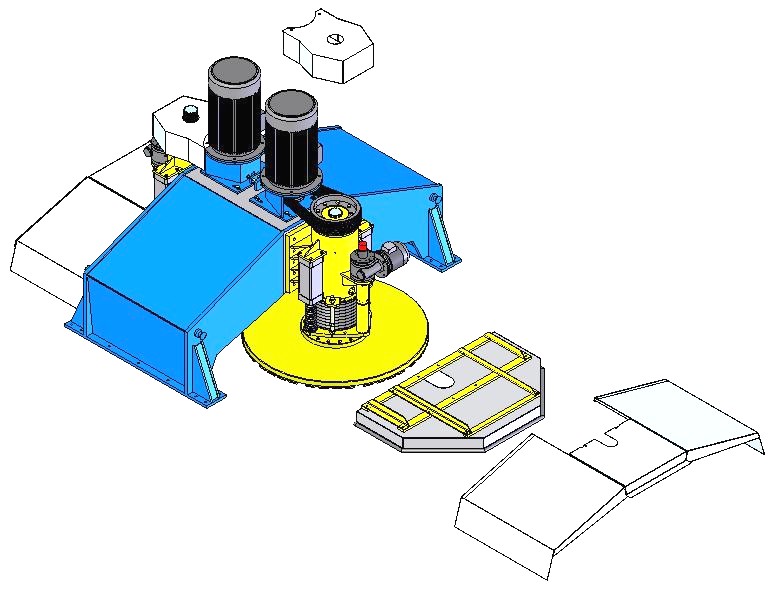

Improving Winning Surfaces With Entrance Calibrators

Maximum Potential of the Equipment Using Thinning and Polishing Heads

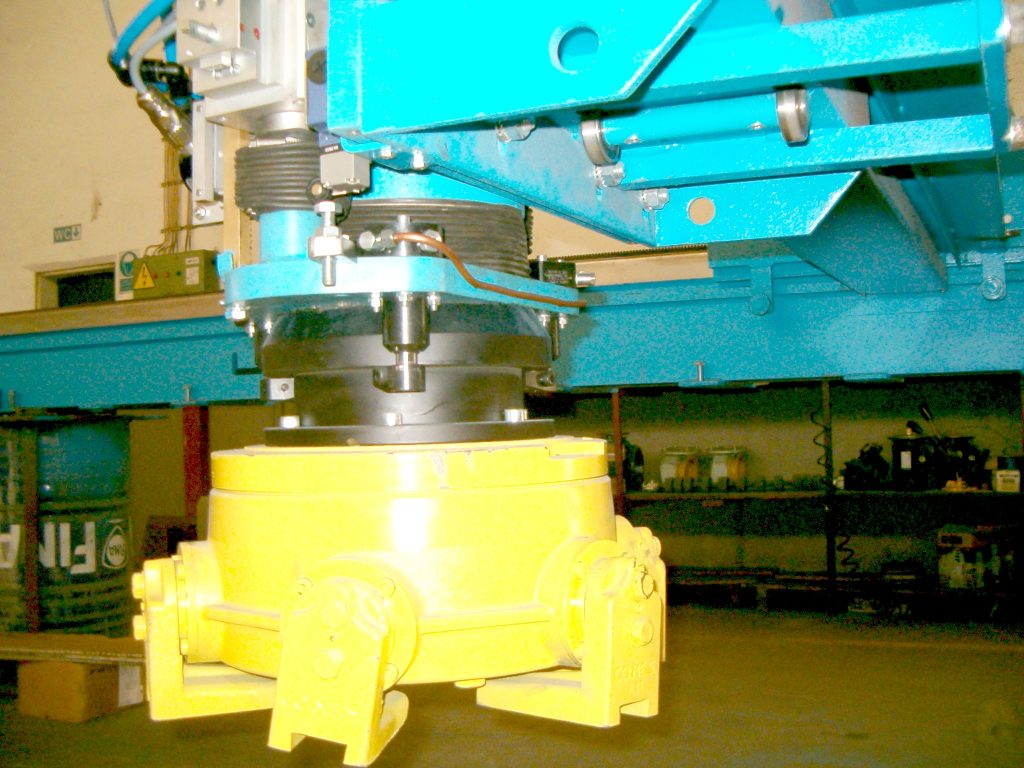

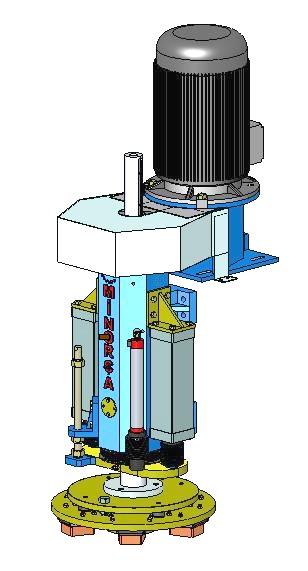

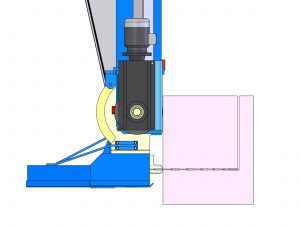

Tested working heads, with double pneumatic movement. Thinning diamond plates with high diameter

The decision to use multiple heads for multi-operations can be increased even after the equipment is installed. At beginning, it’s provided a ram with supports ready to receive all exchange program heads. With this mechanism it is intended that the equipment is constantly evolution and adjust to the market requested by customers.

Polishing head

DIAMETER OF TOTAL PLATE (INCH (in) / MILLIMETERS (mm)) 20 in / 510 mm

DIAMETER OF DIAMOND HEAD TO CALIBRATE 17.5/8 in / 450 mm

LESS PLATE DIAMETER AVAILABLE BY THE USE OF PLATE WITHOUT ATTACHMENT

MAIN MOTOR POWER ADMITTED 10,5 Kw / 15 Hp or 15 Kw / 20 Hp

WORKING ON WITH INVERTER CONTROL AT REGULAR 50Hz PRODUCES +100% OF POWER

PULIES ASSEMBLE MODE TO ALLOW MAXIMUM POWER ALL TIME on defined material

POLISHING HEAD WITH OSCILLATION receive 6 FIKERT attachment

PNEUMATIC CONTROLLED PRESSION double piston

A Solid Program with Capacity to Work Several Dimensions and Hardness

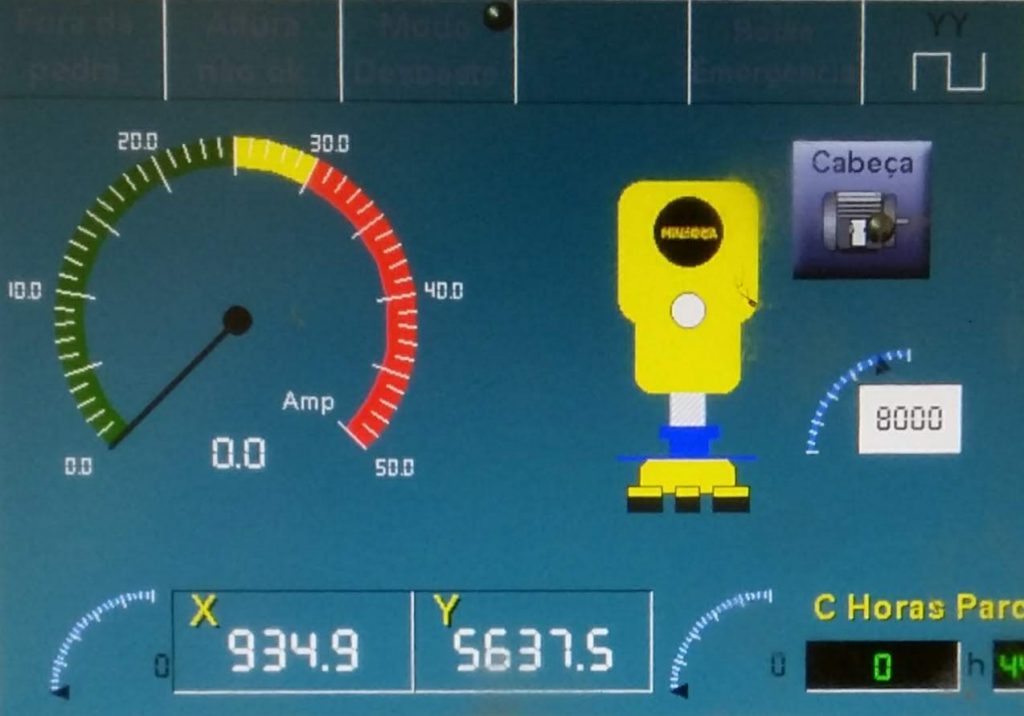

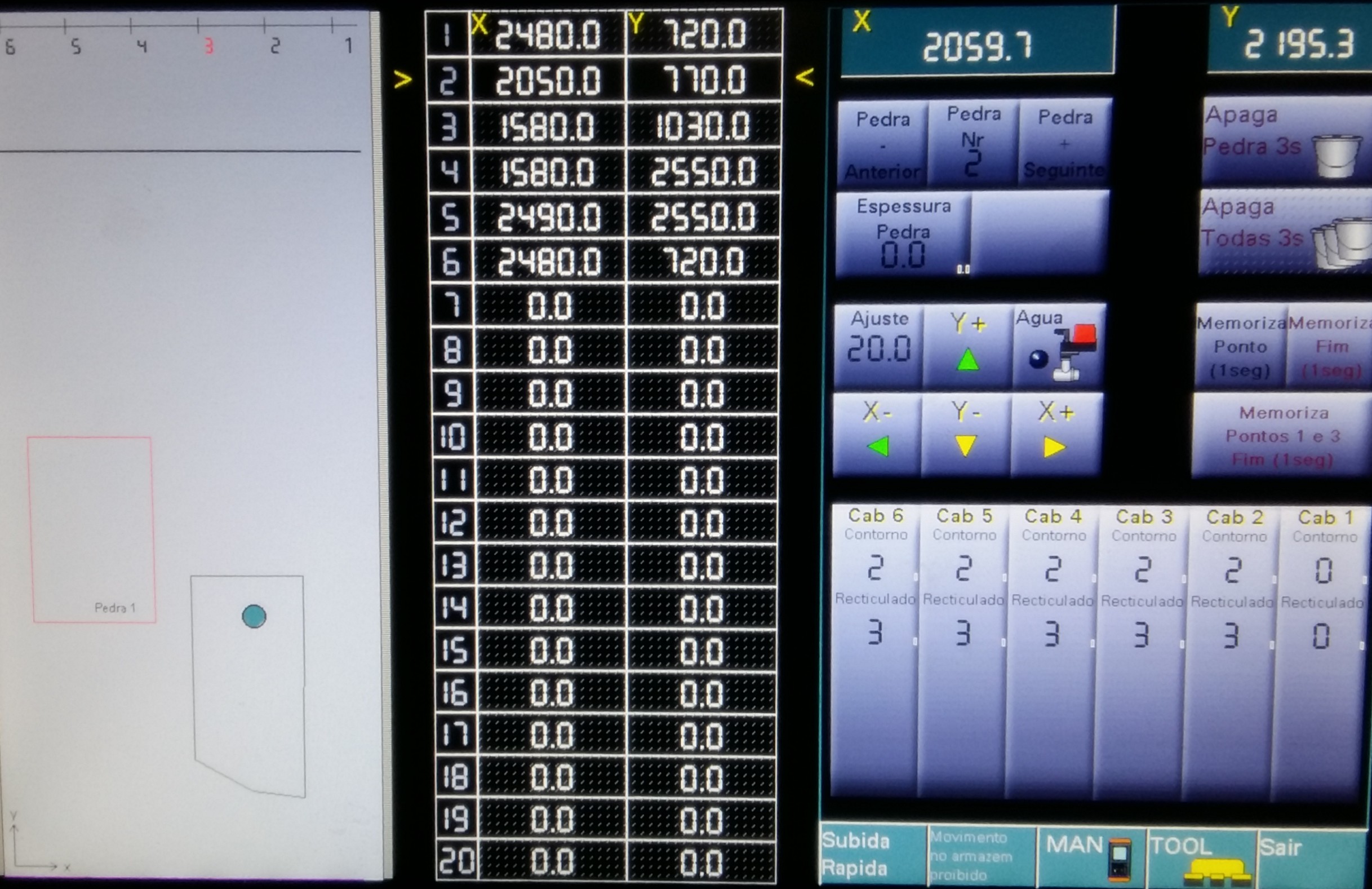

An design program to allow the easy use with all dates on specific screens, will increase the fast exchange of stones while the operator can supervising the priority dates.

Multiple slabs dimensions, also thickness can be edited

The menus show the head position as well the stones, that ones can be inserted in diverses shapes, also hardness or thickness, let introduce multiple pieces on the same space and program the order, the number of passages of each head or abrasive, in every instant can check basic parameters, change menus, pause the working cicles.

In every automation we have in mind, easy understand with maximum potential.

Bigger buttons with easy supervision inspections

As well tested program with the toughen Hercules Series, the equipment provides the polivalency with also the productivity.

Several menus, since the show of material position over the bench as well the measures of it. The speedo checks are easy to understand and provides the adjust of maximum potential.

Program designed to be operated with great simplicity and that ensures most of the works, leaving the user to parameterize several variables in order to ensure the final quality and increase productivity. It’s possible make fast cleaning as time optimizer or repeat several times the cicles to the desired quality and with the final polishing adjustment by use several ways on passages to the final product, ready to receive the mirror commentary.

The program claim is allowed operator without specific expertise on operate the equipment.

Several Potential Allowing Extreme Final Works

With the constant intention of equipment to make the most of it, its development has the polyvalence of can be adapted with the factory needs. To fit in with the constant evolution of the market we have developed several separate accessories that can adapted, anytime, in order to keep the equipment at its maximum performance. It is designed for a for full non-stop operation and maximum utilization of both installed capacity and working time. Therefore, whenever you are on hold you can do lengthy or for stock.

Exist a second table that will be material to be cut in several stages, because the equipment has the ability to pause this operation for direct operation and operator intervention. Through multi-heads you can consider multi-operations, the same surface polishing or production of coating pipes.

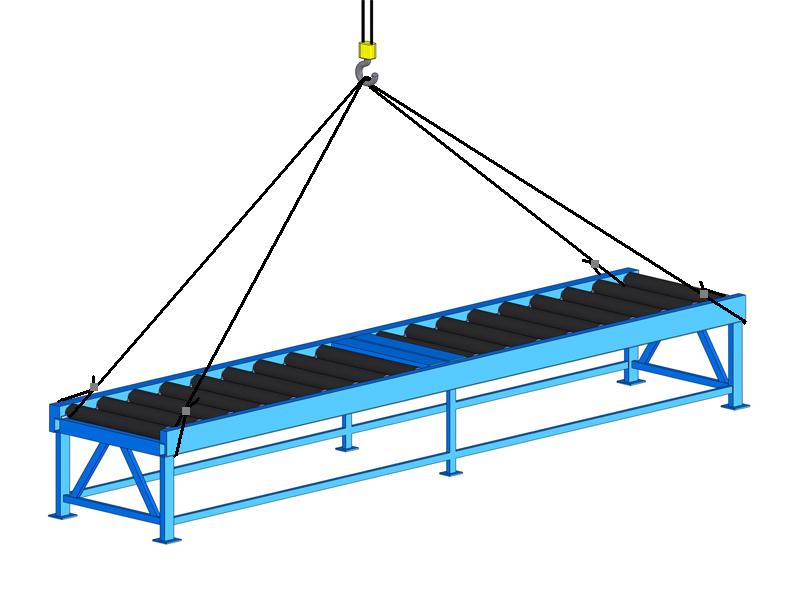

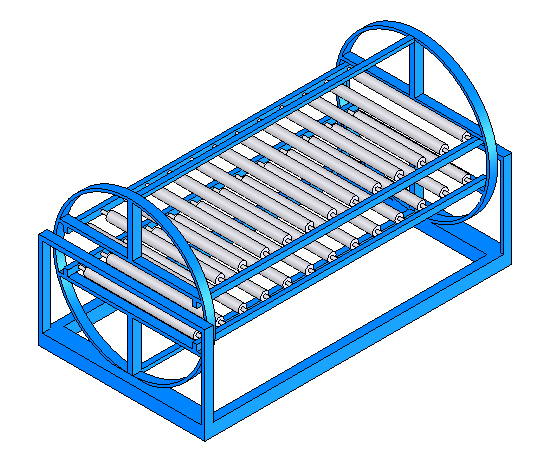

Roller system to movement stripes

Provides the output of cut stone or can increase production downtime by cutting feed strips. The dimensions and the rollers weight capacity can be defined as you intend. 31,1/2 in. / 80 cm ; 63 in. / 1,6 mt. ; 78,1/2 in. / 2mt. and 86,1/2 in. / 2,2 mt. For example, to polish strips, you can order a vacuum autoloader that is inserted above the rollers, and after the process is complete, remove it and insert another stone.

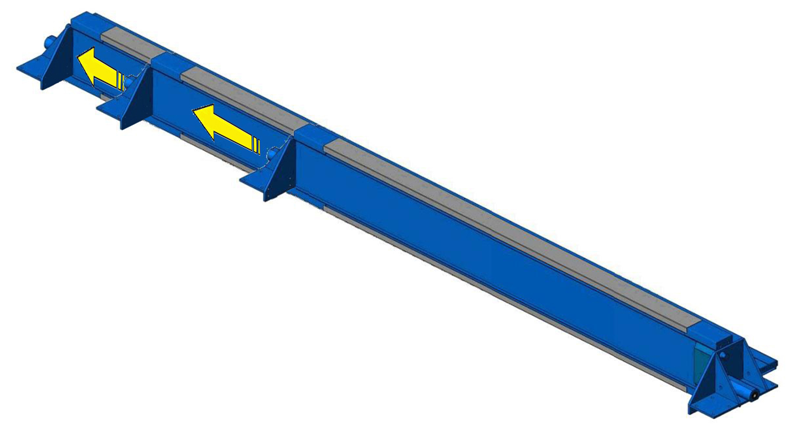

Can Set the Useful Displacement on Lateral’s Until 2×63 in / 2×1,6 mt

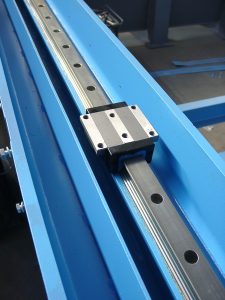

Linear Displacement Over Special Bearings

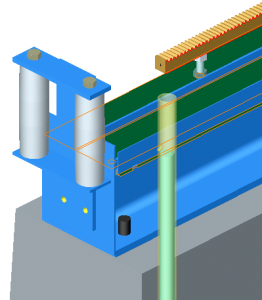

The bridge body works above the rails with weight distribution

The bridge is made of a single solid component and mounts directly to displacement carriages located on side supports and connected to precision rails, and an entire axle connects the double rails by the gear. We guarantee perfect parallelism in all bridge positions. On the side pillars there are several surfaces prepared to receive the rail fastening adjustment, independent of the motorization measuring system, linear bases to receive the precision bearings and also the contact surfaces to avoid high stress lifting.

The bridge body works above the rails with weight distribution

The weight of the rails is always the same regardless of bridge stress positioning, traction and alignment. With an oversized construction, we guarantee perfection on the side rails. All displacement racks are adjustable in positioning and fixed by iron bolts, that ones move from bottom to top of the gear, machining at once, ensuring perfect alignment of parts for a long time.

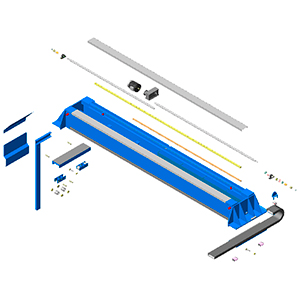

Stainless iron guards assemble

Can mount guards on stainless iron or bellows. We mount the bellows on small displacements, and the stainless 1/8 in. / 3 mm. in all others dimensions. On the top we screwed it and the displacement carriage has a bearing support to allow perfect movement on long distances.

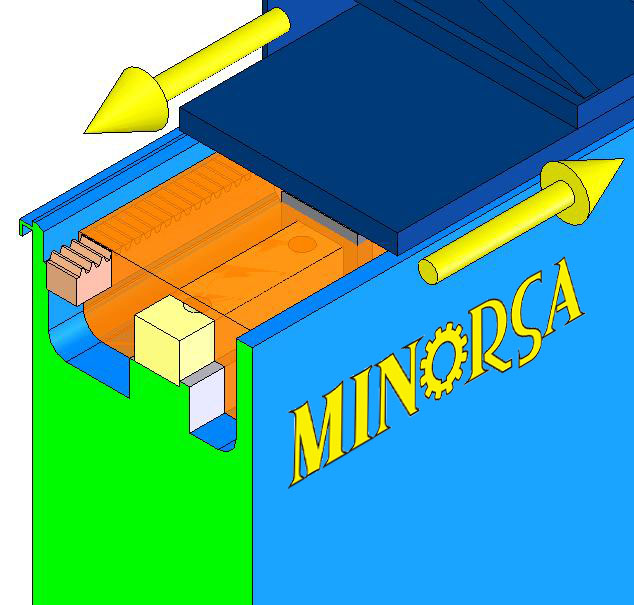

Both pictures show the both sides. The interior has separate boxes to avoid the mud, for oil bath work, the side box has different dimensions on each side, on the mud side there is a system for removing resonance and on the other side the linear bearing guide for providing constant parallelism.

The conception of displacement cars on the rails is removable on assemble

We started using linear displacement bearing guides in 1993. Displacement systems have been developed and refined to increase the power of the cutting saw. The production is and to keeping equipment and finish quality.

Experience and knowledge enable us to ensure that this mechanism is the best option for exploring the equipment in all configurations with cutting benefits.

All equipments are total assembled on factory and subject into an exhausting test control

Small parameters are adjusted in the assembly process, parts are deposited in a transport box, plastics to cover the motors.

Machined surfaces on every alignment parts and support

Working on oversized displacement linear bearing guide with two bearings allows the perfection in all positions and increases the displacement velocity. There are two separate boxes, one can work with oil bath and the other removes the projected mud.

Standard manufacture and procedures

Hercules Series pieces are designed in series to improve their quality as a product, part and component that will integrate the equipment and thus build reliably. If you think in profit and production 24/7 at full time, assemble by working process to ensure the well final product, and check every part after placing it on several components to send to final address.

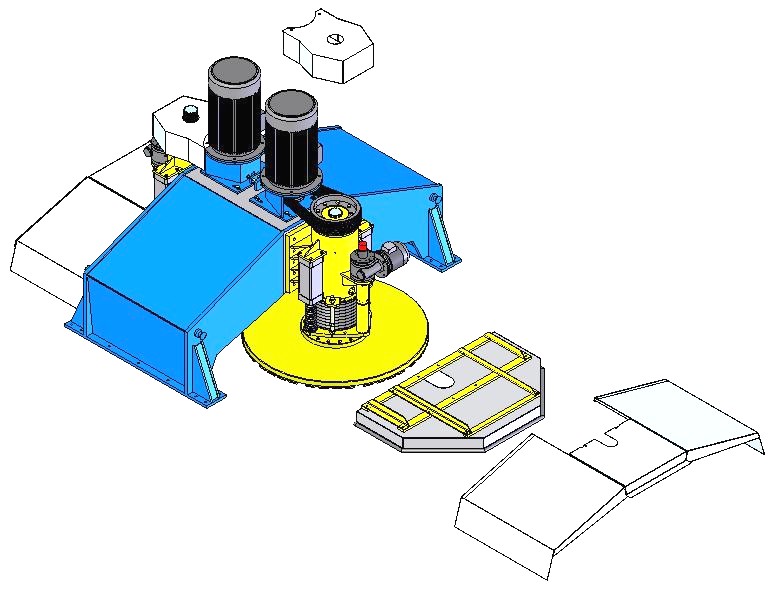

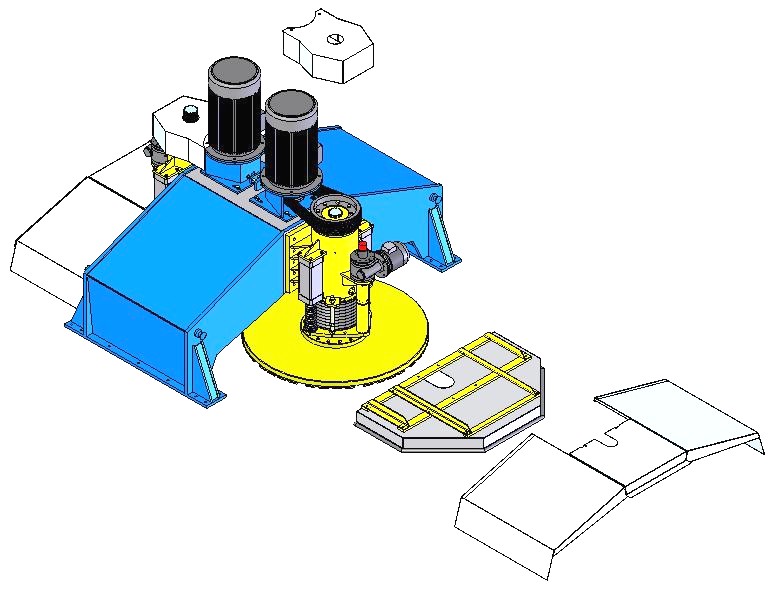

Primary thickness tune 43,1/4 in / 1,1 mt plates

About

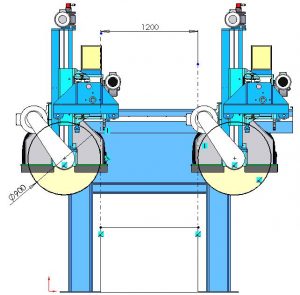

Twin Calibrators weighs above 13,000 lbs / 5,9 tons. (Only this proper body)

Technical Features

✓ To work Marble / Limestone

✓ Primary diamond plate diameter: until 1,100 mm. (37 Kw diamond plate x2)

✓ Tickness capacity (std) 4 in / 10,1 cm (until 5,5 in / 14 cm

✓ Maximum width on 1 piece belt for operation 31,1/2 in / 80 in ; 43,1/4 in 1,10 mt

With off center multi-heads 63 in / 1,60 mt ; 82,1/2 / 2,09 mt ; 126 in / 3,2 mt

Solutions to Provide More Working Freedom Around Polisher

For each type of work, we have a more suitable bench solution

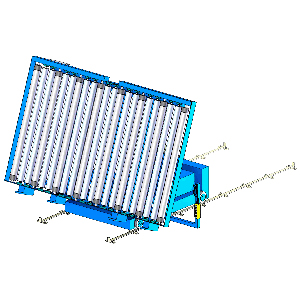

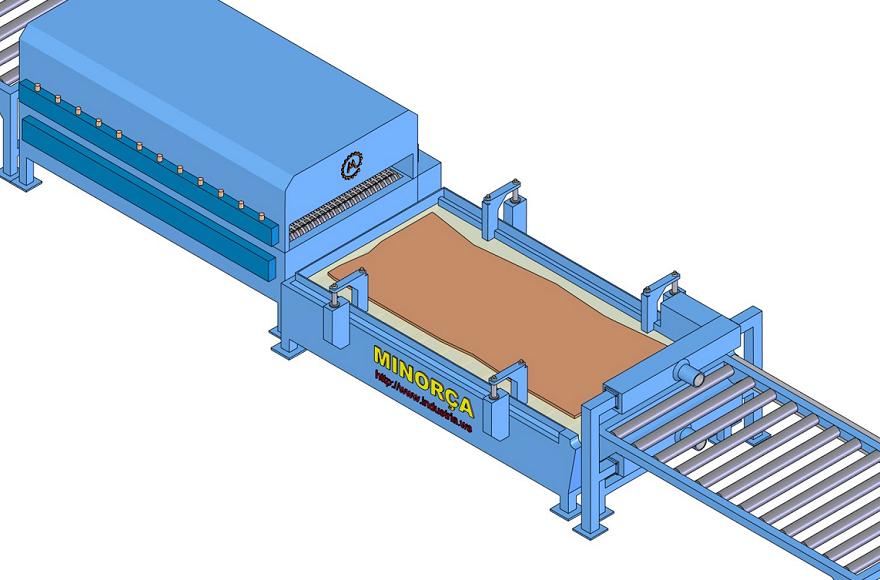

Tilt bench

Tilting bench to get the stone with vacuum system.

Will provide the continuous supply of slabs, the metallic rollers are motorized to move the material into the conveyor, with hydraulic tilt lift will allow hi thickness work, the movement of body is electric over rails.

Roller tables to provide more slabs

This workbench allows the equipment to work non-stop between major jobs, gaining moments of material change. It can be supported by a loading / unloading robot, can use a system to lift the material in the cutting process, and even has several pneumatic pistons to align the material with the saw. Usually it comes with engine rolls. The width starts on 31,1/2 in / 80cm and the standard length is 118 in / 3m plus on main body plus the exit rollers until pallets, those bodies can be made until 236in / 6m and assemble it together.

Rotating table to provide twin slabs

Line Systems to Add Resine

Easy imersion system with 4 side pistons to move up and down the bench with slab

With all our Ranges we are Able to Offer a Total Choice

Bridge with several lengths as the heads assemble

Special demand length up to 472.1 / 2in / 12m to allow multiple stones in the same cutting motion. Since 1993 we use this displacement system and in 2012 the oil bath capacity.

Serial production of well tested components used for several gamas

Surface treatment on metal components. Steel grit blasting grease removal, and thermally applied zinc coating. This protection is reinforced with an anti-deterioration / aging finish by means of an undercoat, a graphite rubber component layer and high gloss paint top. Hence, we guarantee maximum anti-corrosion protection against its common operating environments.

ALL EQUIPMENT STRUCTURE is designed in forged steel using MIG welding

Independent counting system on appropriate measuring rack. It is an equipment with protection guard and stainless-steel bellows, and that support bearings to keep maximum saw pressure on stone.

Fast and Easy

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Standard And Tested Components Offers Reliability

The Hercules series adopts the principle of using common parts by changing their sizes by gammas.

Standard Parts In:

Automatic lubrication on all displacement points: water on/off automatic valve

The auxiliary components are also selected for their good operation and easy maintenance, and the security systems are assembled for easy identification and protection from events.

Power failure recovery (position and status memory) to continue working automatically, saving time and materials to be cut;

Automatic cut-off stop protection, if material gets stuck, slow down or at the end of the program;

Automatic axle stop/protection in case of mechanical anomalies during operation;

Displacement stops cease working to avoid programming or operation errors;

The equipment stops when opening the electrical panel;

Low voltage manual control switch to protect operator;

Electric protection by using magneto thermal switches (without fuses);

Regulated power supply, protecting low voltage circuits against power surges;

The equipment stops after encoder pulse count failure or contactor obstruction;

Horizontal displacements in oil bath capacity.

Automatic lubrication system with times, which allows keep the equipment lubricated at all its constant movement points, without the need operator interventions with oil pressure switch in case of pressure loss in the circuit.

The displacements can be fully embedded in oil bath, eliminating supervision and increasing time between periodic maintenance. Thus, allow increasing its lifetime.

Water pressure system control/protection on cables by cover mesh/pressure water pipes

Special electric cables with mesh sheathed, moved through the cable supporting rails. Measure Encoder component with braided wire mesh cables (counting system) to protect against power surges. The base installation also has inner lined water cables consisting of a mesh reinforced rubber hose inside. Shields and rails for collecting the oil coming from lubrication of material used for cutting. Water pressure switch to control cooling and washing of the saw. (Placed on top of pillar for greater accuracy).

Electric board disconnected of equipment

A pit dimensioned with spaced components and embedded screen. The plate is separated from the machine to avoid vibrations and has easy access, because it will be installed close to the floor. This electrical panel is built in our facilities in compliance with all CE regulations.

Electrical panel ventilation system with temperature control. Software under development to facilitate data entry and reading, based on operator feedback and questions. Mains fault detection system.

Standard components of well reputed brands

Using reputable brand components and applying operating concepts ensures full operation in the future.

Multiple benefits and aid capabilities:

Managing several pieces of equipment from a main computer in the office through ethernet (sending production orders);

Ability to receive and operate complex draws or cutting cycles programs;

Production / cost control through a total hour counter or by works, and a total area counter, by works or saw;

GSM or WEB text messaging system that lets you know that the job is done or if there are any errors in the cutting phase;

Signal emission to check the condition of equipment at a distance.

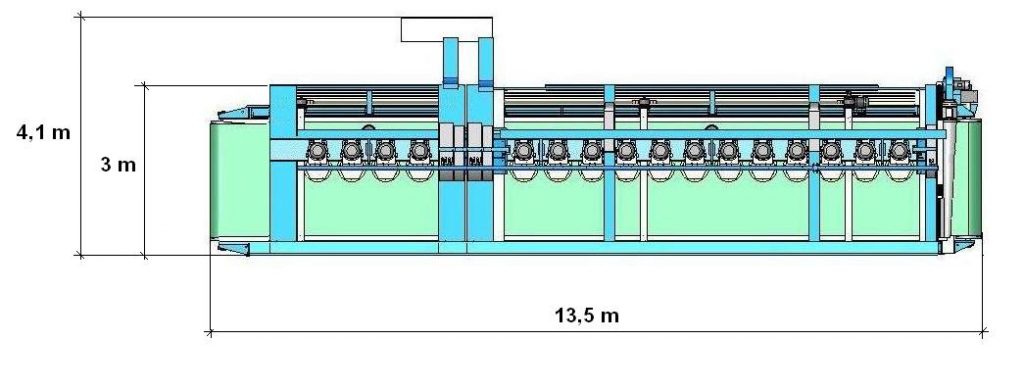

Machine Dimensions Overall Occupied Space

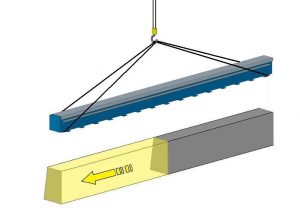

Accommodate Slipping

We provide an important solution to overseas market, allowing the polisher transport on container, we have the ability to manufacture the table body on 2 pieces, that will ALLOW PLACE THE PARTS ON THE INSIDE CONTAINER, prevent the salt over structure, those pieces are entire milling with the laterals made over same machining, that process will guarantee an perfect alignment of all components, is more expensive but allow quality overseas transport. On place machine assemble it will the both bench parts bolted and assembled an special top bench frame over 2 sides.