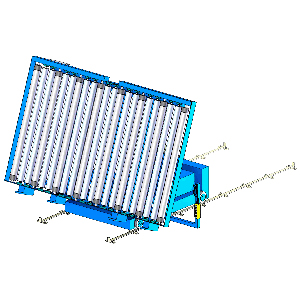

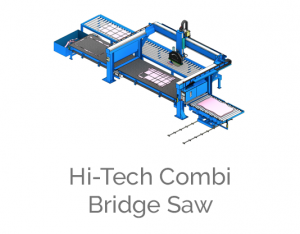

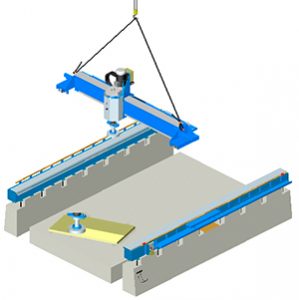

Multi-Head Polishing With Alimentation

About

MARBLE, LIMESTONE, SANDSTONE or GRANITE, BASALT SLAB POLISHING MACHINE

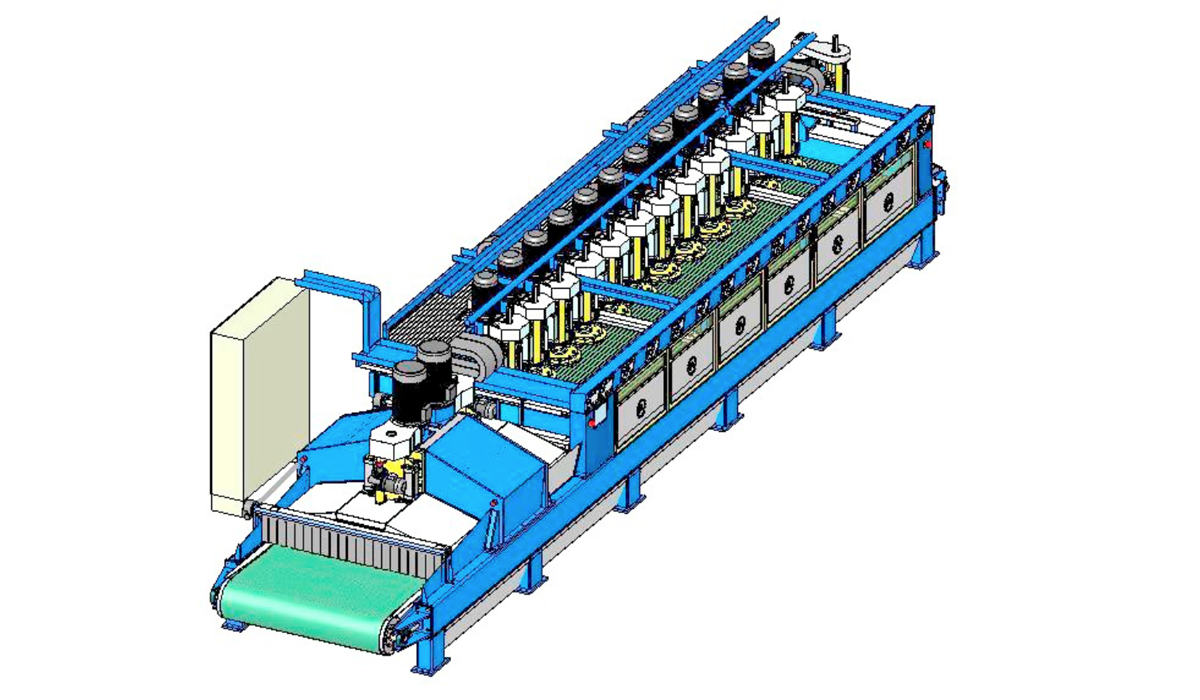

Can be fully disassembled for easy transportation in containers.

Fully rectified on the worktable and lateral sides.

The milling is done all at once in our ten meter long capacity machine.

We guarante full alignment.

Cnc machined.

The worktable is reinforced for a stable operation.

After the anti-corrosion treatment with zinc, all the elements receive a primary paint and a final layer of textured paint (paint with particles to improve protection).

All equipment elements are fully tested before the final assembly.

Weighs above 32,5 tons.

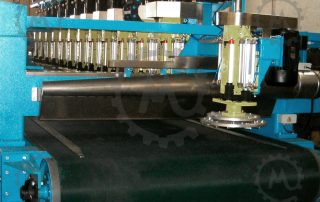

The work table has several grooves so that the conveyer belt can operate with the less possible friction.

The structure is steel blasted and the surface is hot-zinc coated.

Its oversized dimensions allows for an excellent polishing power with high-end quality.

Can be assembled according to the material you wish to work.

Technical Features

✓ To work Marble / Limestone

✓ Standard engine power / nr.of heads 10 Kw / 12+2+1

✓ Primary diamond plate diameter: until 1,100 mm. (37 Kw diamond plate x2)

✓ Polishing plate / head diameter: 490 millim. (6 pads each)

✓ To work Granite / Basalt:

✓ Standard engine power / nr.of heads 15 Kw / 12+4

✓ Primary diamond plate diameter: 450 millim. (3 grindstone each)

✓ Polishing plate / head diameter: 510 millim. (6 pads each)

✓ Tikness capacity (standard / optional) 100 millim. (until 140 millim.)

✓ Protection doors in alluminium and tempered glass

✓ Total installed power 240 Kw / 330 Hp / 450 Amp.

✓ Maximum width on 1 piece belt for operation 800 ; 1,100 ; 1,600 ; 2,100 millim.

✓ Standard type if admissible pads type Fickert

✓ Water consume (Lts/Min.) between 500 to 700 Liters (depending the type of heads)

✓ Necessary space to work (plus tables) 14 meters (plus 12 or 18 meters) aproximate

✓ Weight above (Kg.) since 28,400 to 32,600 Kilos without in and out tables

Main Feature & Related Equipment

Polishing Equipment

Can also be adapted to other machines & if you intent please see any follow machine

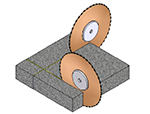

Works Machine

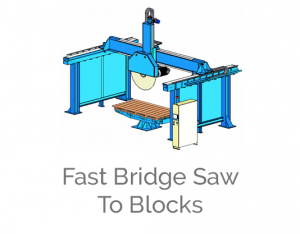

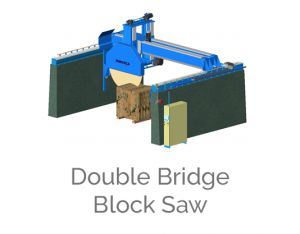

Execute 90 Degrees Cutting Angle

In automatic execution can program both cutting sides

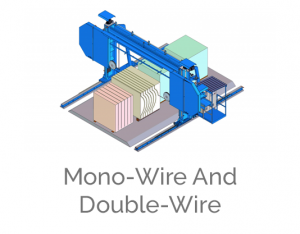

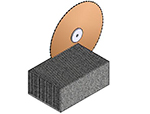

Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting

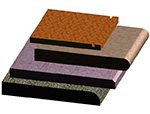

Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can polishing the edges and put it in several shapes