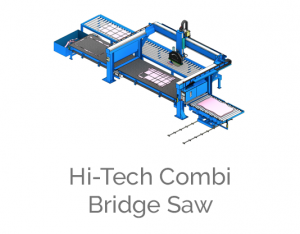

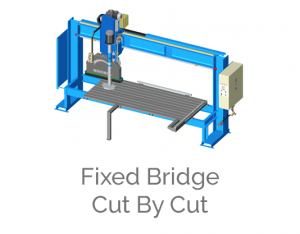

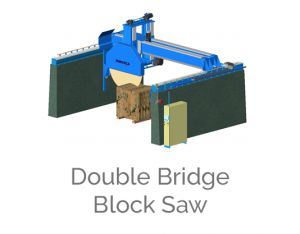

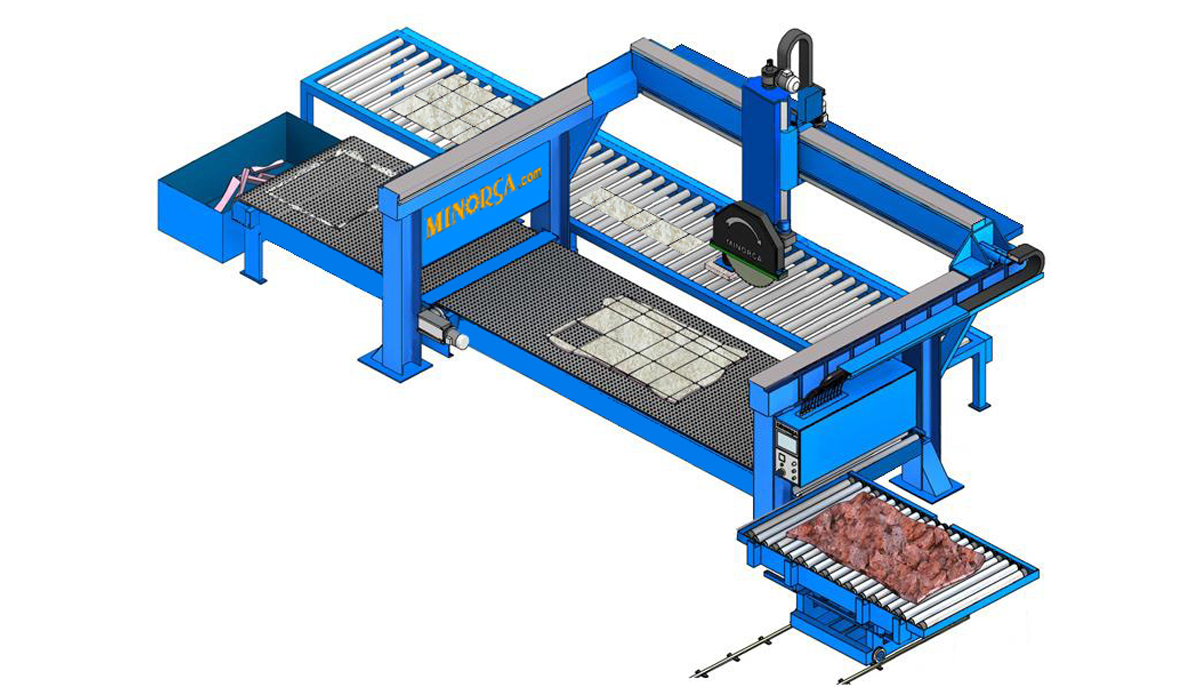

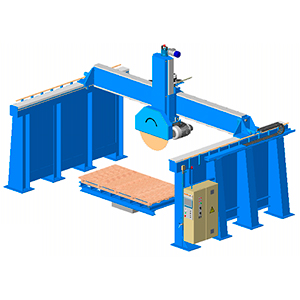

Hi-Tech Combi Bridge Saw

About

It can be assembled with several options, making it the most profitable and precise cutting equipment.

Technical Features

AN HI-TECH SAW, THE HERCULES SERIES GAMMA 300 & 500 ON BELT CONVEYOR ALLOW MORE EXPLORING CAPACITY AND POTENTIAL FOR TURNING, PROFILING, AUTOMATION LOADS WITH BELT CHARGING AND HI THICKNESS SLAB TRANSPORT SYSTEM. YOU CAN MOUNT ONE OR TWO INDEPENDENT CUTTING HEADS.

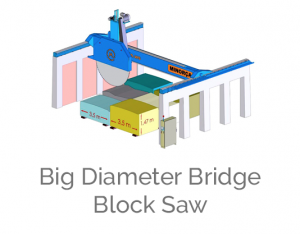

✓ Diameter of the disc permissible – 450mm to 900mm (1300mm)

✓ Maximum cutting height – 325mm (Falange 250mm) 510mm = 1300

✓ Vertical displacement minimum – Z= 667mm (p/+ optional)

✓ Cutting capacity – X= 2100mm; Y= 3700mm (p/+ optional)

✓ Power of main motor – 15kw (20hp) / 22Kw (30Hp)

✓ Maximum height required for operation – 3.7mt to 4,1mt

✓ Distance between inner headboards (p/+ optional)- 5,5mt

✓ Cutting displacement velocity’s – 20 or 37 mt/min.

✓ minimum peripheral speed for cutting – 28 or 35mt/sec

Main Feature & Related Equipment

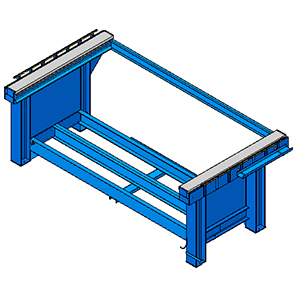

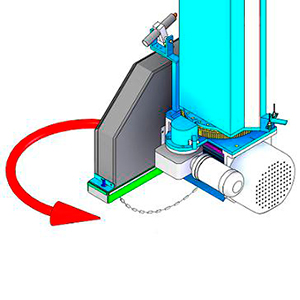

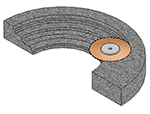

Rotary Bench

In automatic rotation allows every degree stop or continuous movement to profil, supports above 12tons; possibility to assemble manual indexation every 45 degree, in that mode will support above 6 tons.

Can also be adapted to other machines & if you intent please see any follow machine

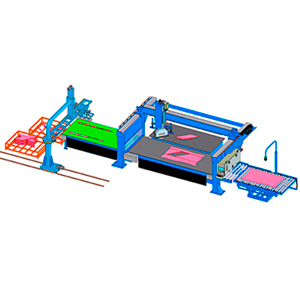

Particular Cad Draw Programing

With the internal use of cad system the machines can cut surfaces without outsides recurses

Can also be adapted to other machines & if you intent please see any follow machine

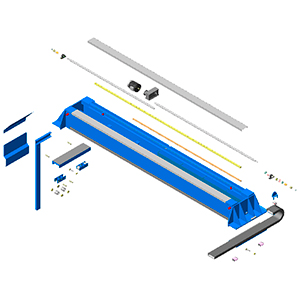

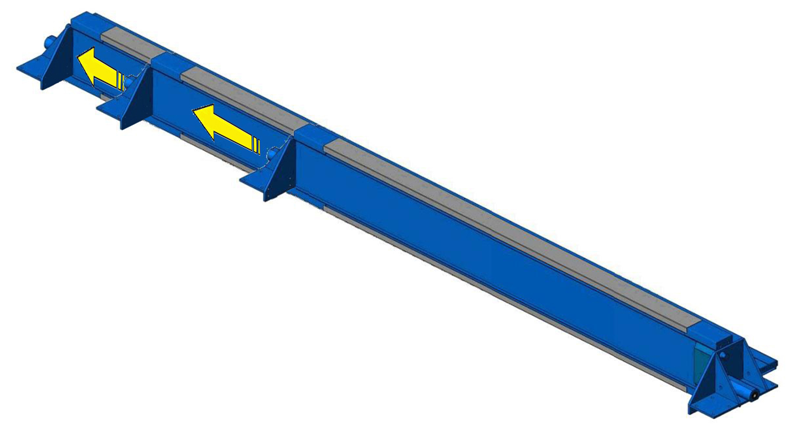

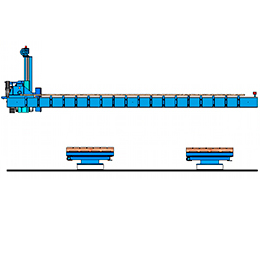

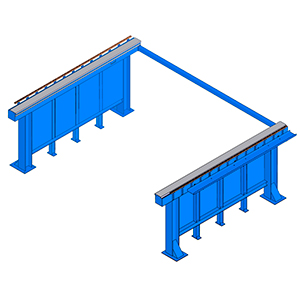

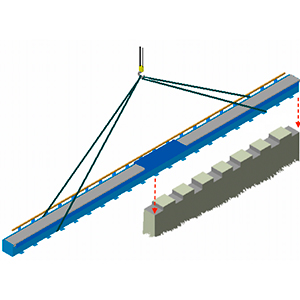

Several Length on Bridge

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

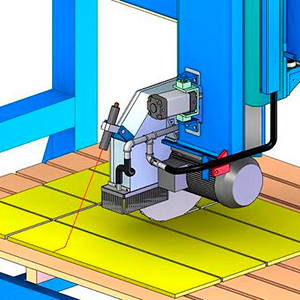

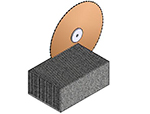

Rotating Cutting Saw

Can also be adapted to other machines & if you intent please see any follow machine

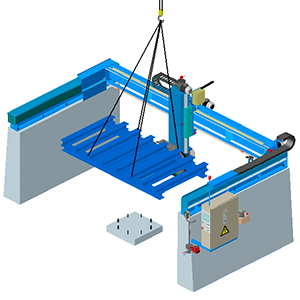

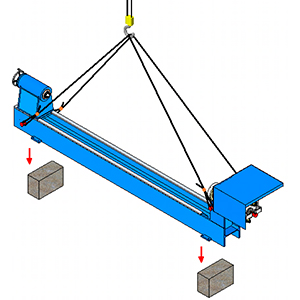

Monobloc Frame Transportation

Can also be adapted to other machines & if you intent please see any follow machine

Increase Potential

Can also be adapted to other machines & if you intent please see any follow machine

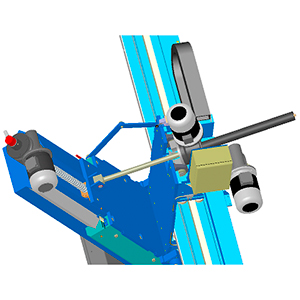

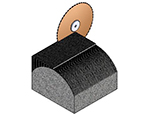

Inclination Head

Allows mitre joint cut since 1 until 45 degrees with several cutting cycles, no scar the stone

Can also be adapted to other machines & if you intent please see any follow machine

Lateral Pillars High Dimensioned

Can also be adapted to other machines & if you intent please see any follow machine

Metallic Pillars

Can also be adapted to other machines & if you intent please see any follow machine

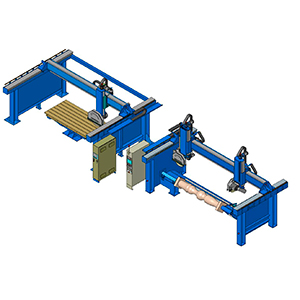

Lathe Body to Bridge Saw

Can also be adapted to other machines & if you intent please see any follow machine

Multi Accessories to Cut Rentability

Can also be adapted to other machines & if you intent please see any follow machine

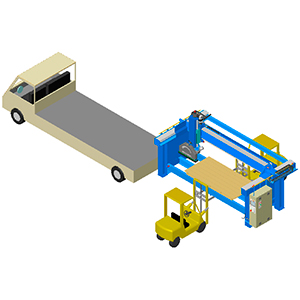

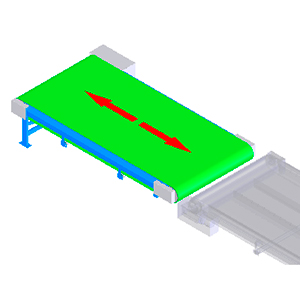

In and Out Belt Table

Can also be adapted to other machines & if you intent please see any follow machine

Laser Focus to Alignment

Can also be adapted to other machines & if you intent please see any follow machine

More Displacement on Lateral Pillars

Can also be adapted to other machines & if you intent please see any follow machine

Works Machine

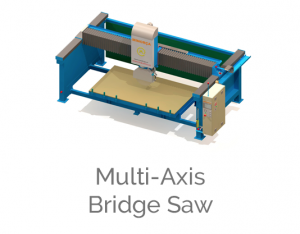

Multiple Axes Movement At Same Time

Can make profiles using several axes, depending of the control system it’s possible execute programs generated on cad cam system outside or in proper cad on control machine, the cutting parameters can be changed on machine, the final work quality it’s defined by quantity of cross cut

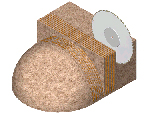

Saw Round Profile

By proper program can program the diameter, the rope quantity, the proper higher, the final work quality

Water Treatment System

Allows the factory work with clean water, works in closed circuit the mud can be separated with an small humidity, theres several models adopted to all sizes of factory’s

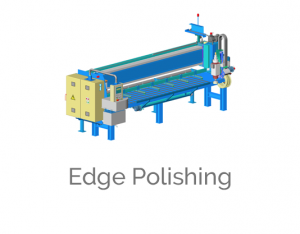

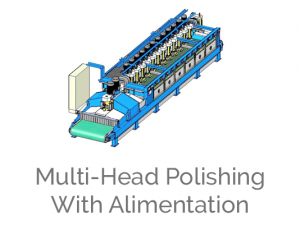

Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can polishing the edges and put it in several shapes

Balustrade And Columns In Round Shape

Can do with proper cad program worked stones in several materials and also forms, like final quality, that one can be perfect, ready to polish

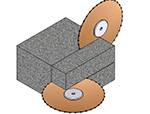

Profiling With Horizontal Saw

Can do that in several systems, the most fast and cheaper it’s coordinate the automatic rotation bench supporting above 12tons with the cutting head, can also work with the horizontal saw mixing several axes or milling the stone

Work Horizontal And Vertical

The saw can rotate and execute several cuttings on both angles

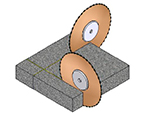

Execute 90 Degrees Cutting Angle

In automatic execution can program both cutting sides

Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting

Tilting Saw For Angles Cutting

Theres two systems for angle cutting, the tilt head it’s the most cheaper, rentable and gives perfect finishing, the dual movement of axes can do the process also with the saw inclination axe

Surface Profiling

With one axe movement each time can produce forms by draw in a proper program on the machine