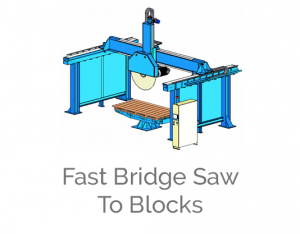

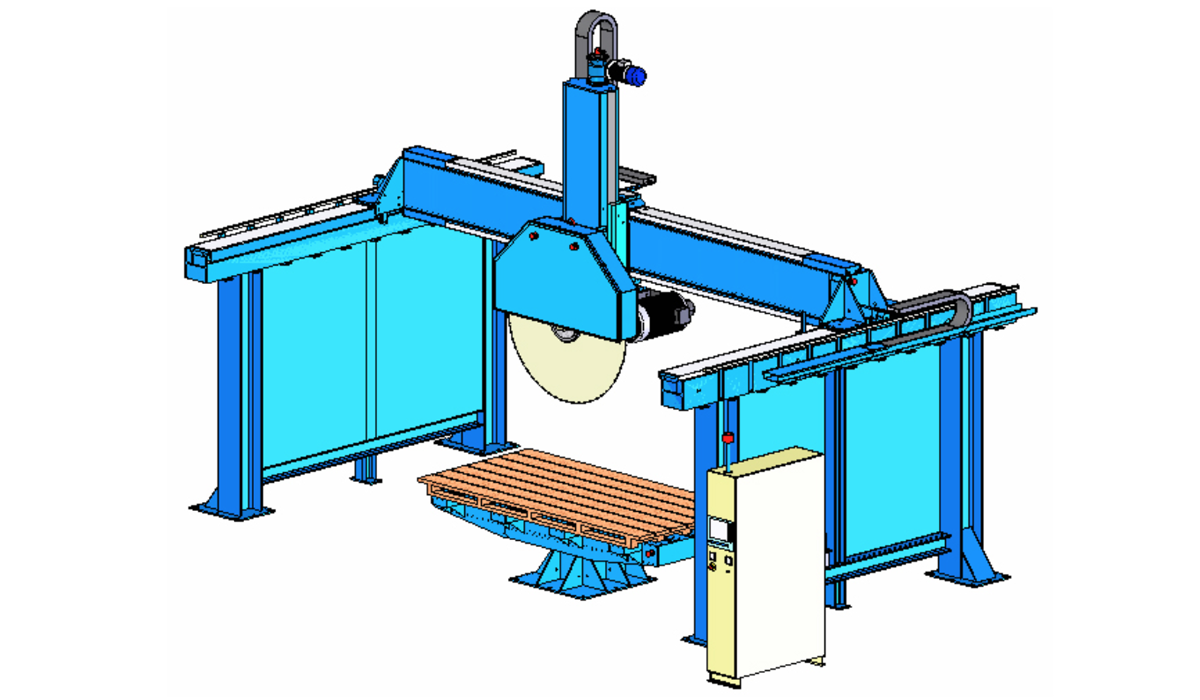

Fast Bridge Saw To Blocks

About

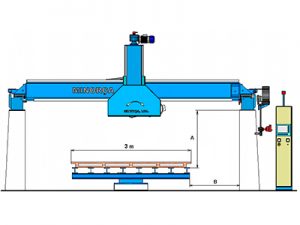

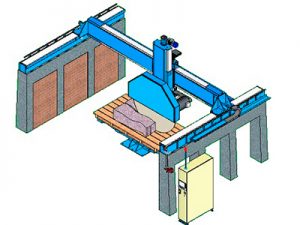

Equipment to cut granite in semi-blocks.

This model, due to its high performance, lack of loading tables, fully tested to start operating immediately, has a very affordable price and technical specifications that make all the difference.

Dimensions in millimeters.

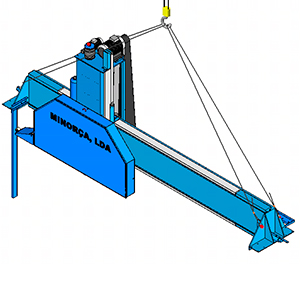

It needs a 40 foot container

It can be ordered in bigger dimensions:

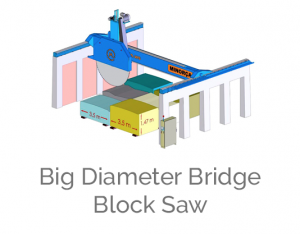

Bridge Machine for a 2,100mm saw

Model MP 12A

Base equipment characteristics

Model designed and developed in 1989, constantly tried and tested, with more than 60,000 working hours.

Materials and components

-Automatic lubrication system

Programmed to work at the same time as the equipment. Supplies oil to all the moving parts, giving more freedom to the operator, who just has to check the level and give signal when it reaches the minimum.

– Structure

Octogonal cutting machine, fully steel-built, mig welded and ready to put all the necessary components for a precise operation.

– Security and operating components

Cooling water solenoid valve.

Water pressure switch.

Movement electromagnetic sensors.

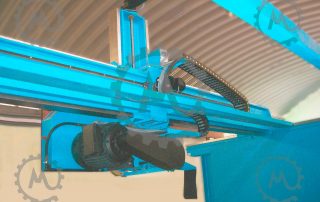

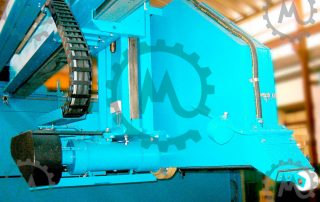

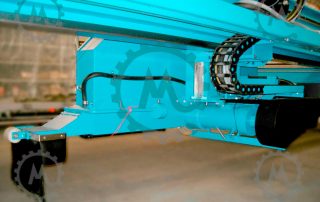

Articulated cable trays

V Belt transmission

Mesh reinforced saw cooling hose

Ultra-flexible electric cables wrapped in steel mesh and rubber.

Stainless steel displacements / bed protective plates.

Displacements control with constant analysis through encoders and precision gears

Oil collection through tap.

– Main Electric Panel

In sheet metal, IP55 standard. Separated from the machine to avoid any vibrations.

Equipped with:

Internal temperature control thermostat

Forced ventilation.

Electronical variable speed drives for individual displacements control.

Technical Features

MUCH PROFITABILITY IN SPEED AND PROGRAMMING

✓ Maximum cut height : 850 millimetres (p/+optional)

✓ Cutting saw support bracket : 400mm

✓ Cutting head Z-axis: 1,000mm (p/+optional)

✓ Cutting saw descent control through a speed regulator / (inverter / frequency converter), counting system by means of an encoder and stop control using a 2,2Kw engine.

✓ Cut travel : above 3,600mm (p/+optional)

✓ Travel / displacement cut regulation by programming, with counting by encoder and electrical engine 1,5Kw

✓ Displacement travel and block placing capacity: 3,700mm with 5,500mm supports (p/+optional, only on concrete pillars with 6, 8,5 or 10m.)

✓ Mounted over concrete or metal pillars with 5,500mm long supports.

✓ Cutting bridge displacement by using an electrical engine with 1,5Kw and speed control. This allows for maximum displacement speed and great precision when positioning cutting measures.

✓ Cutting engine power at 50hz = 37 Kw / 50 Cv (72 amps maximum)

✓ Use of pulleys and V-belts for the saw support spindle

✓ Equipment weight: approximately 7,000 kg

✓ Maximum operating height: 5,100mm

✓ Internal distance between supports: 6,600mm (p/+optional 7,1m)

✓ Maximum cutting speed: 20 METRES / MINUTE

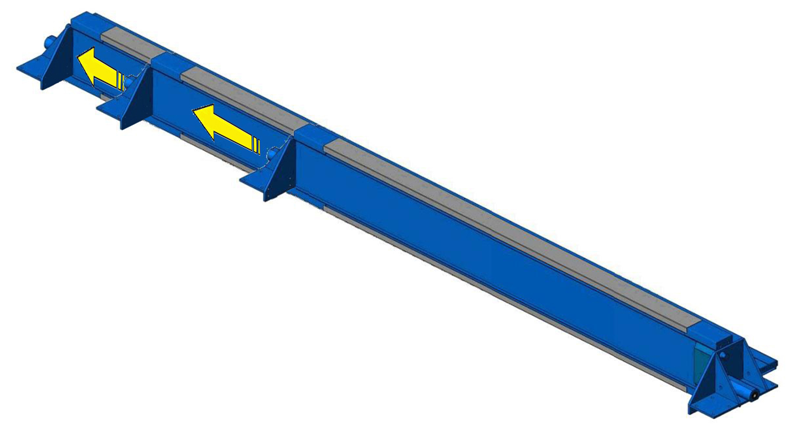

✓ displacement system using linear guides allowing hardly any friction and increased cutting power.

✓ Cutting saw minimum peripheral speed: 26 metres /second

✓ All of the control and speed changes are made by means of a variable drive.

Main Feature & Related Equipment

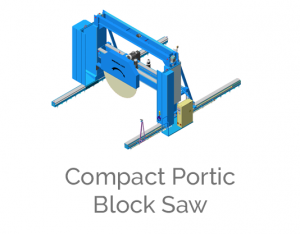

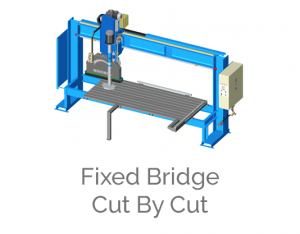

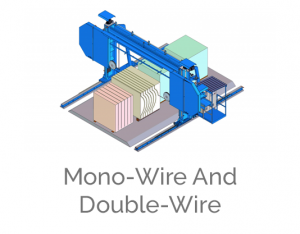

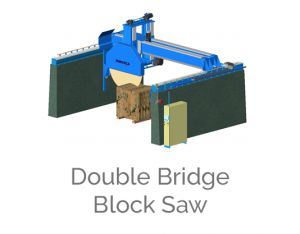

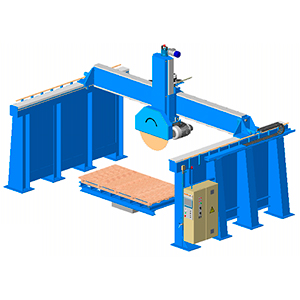

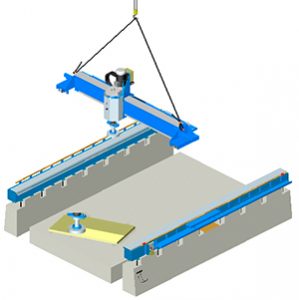

Block Cutter Saw on Mono Bridge Concept

That Models are able to cut blocks until 58 inch / 147cm with an low production cost.

Can also be adapted to other machines & if you intent please see any follow machine

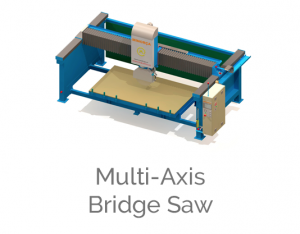

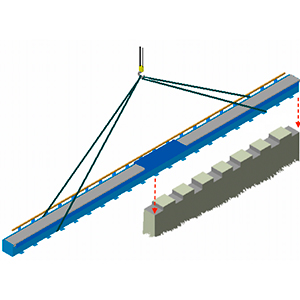

Several Length on Bridge

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

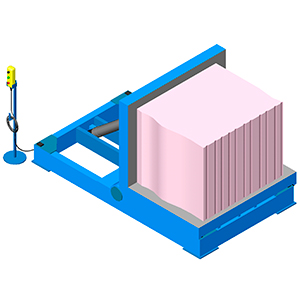

Horizontal Tilt

Horizontal cut position, allow automatic cycles and several disk diameter, with an rotating bench can make an fountain.

Can also be adapted to other machines & if you intent please see any follow machine

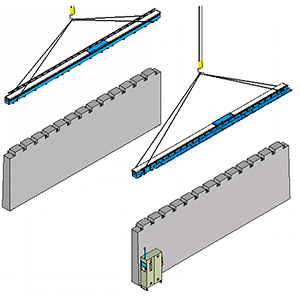

Concrete Pillars

We have available an selection of bridge length and also head length, gives the possibility to increase the diameter and also the cutting travel.

Can also be adapted to other machines & if you intent please see any follow machine

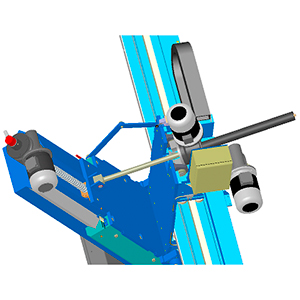

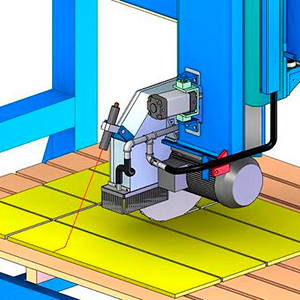

Inclination Head

Allows mitre joint cut since 1 until 45 degrees with several cutting cycles, no scar the stone

Can also be adapted to other machines & if you intent please see any follow machine

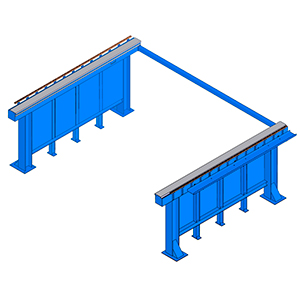

Lateral Pillars High Dimensioned

Can also be adapted to other machines & if you intent please see any follow machine

Metallic Pillars

Can also be adapted to other machines & if you intent please see any follow machine

Block Tilt Bench

Can also be adapted to other machines & if you intent please see any follow machine

Polishing Equipment

Can also be adapted to other machines & if you intent please see any follow machine

Laser Focus to Alignment

Can also be adapted to other machines & if you intent please see any follow machine

More Displacement on Lateral Pillars

Can also be adapted to other machines & if you intent please see any follow machine

Video

Video

Works Machine

Water Treatment System

Allows the factory work with clean water, works in closed circuit the mud can be separated with an small humidity, theres several models adopted to all sizes of factory’s

Allows The Use Of Several Tools

Receiving and machining file generated by cad cam system, the equipment produces the final product using several tools, also the displacement axes can be adopted to the type of work using our several bridge and cutting head models