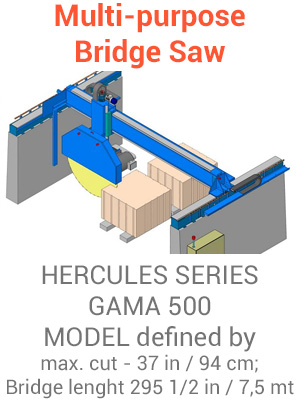

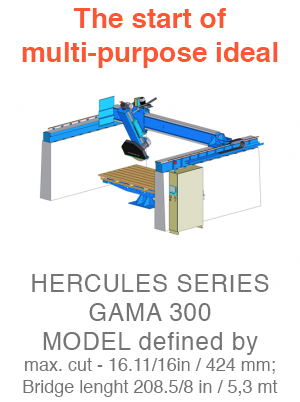

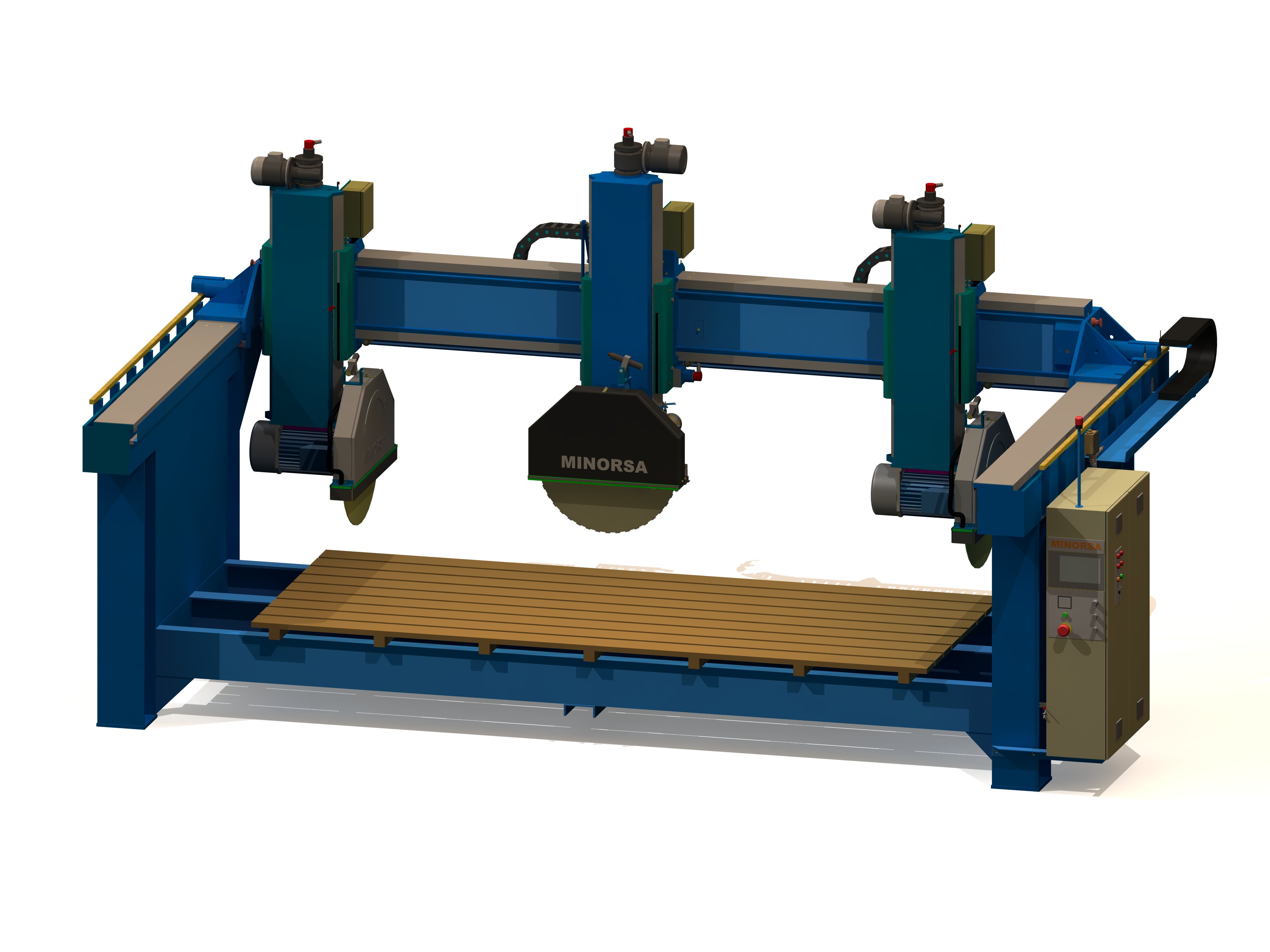

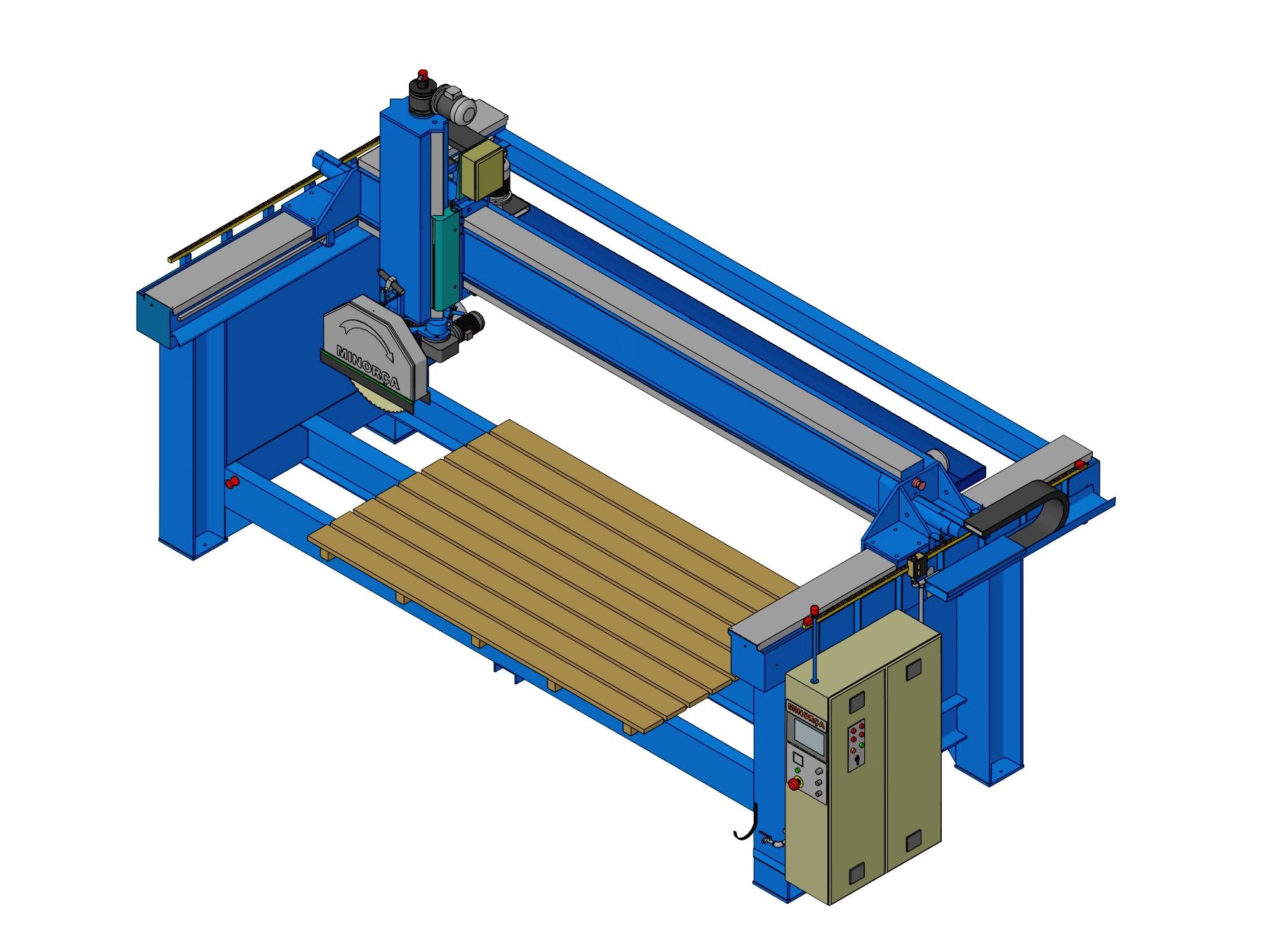

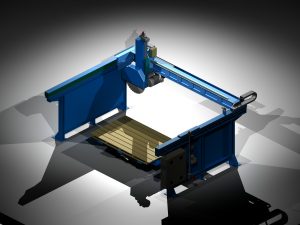

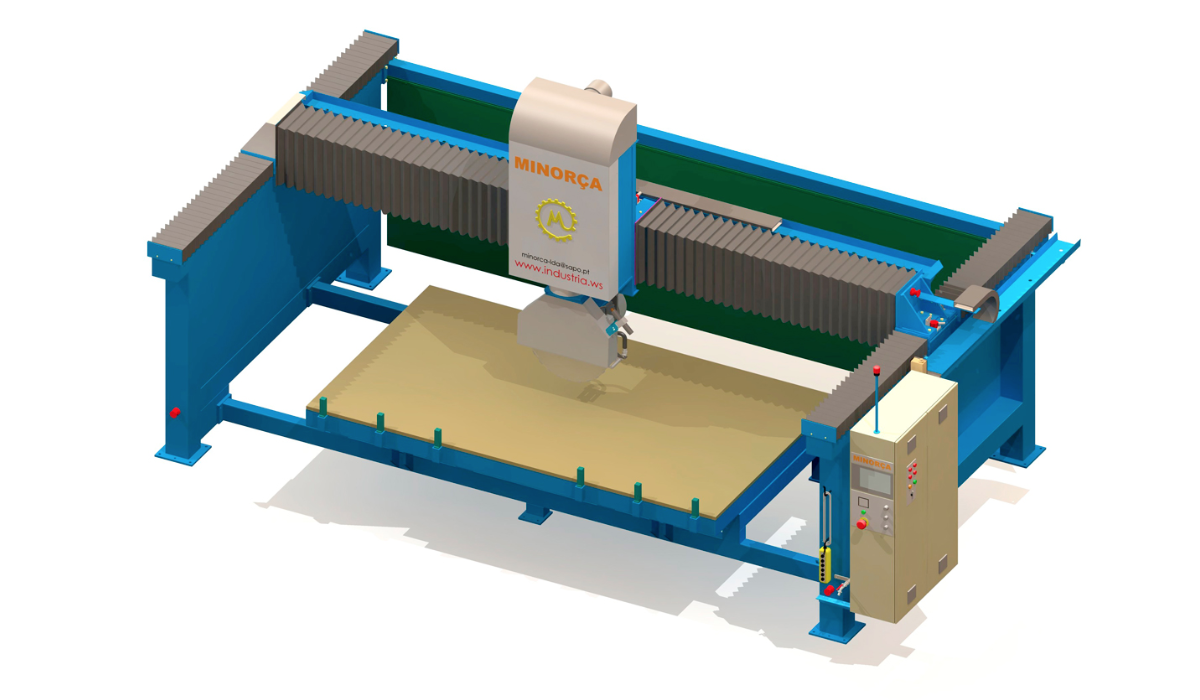

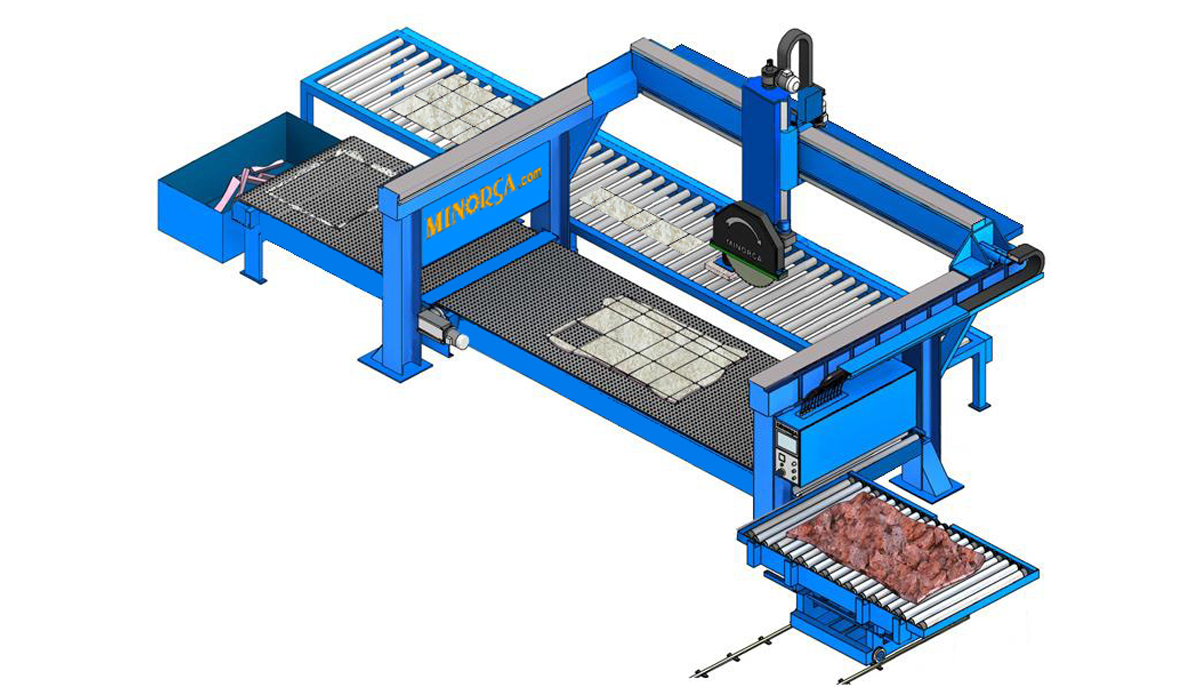

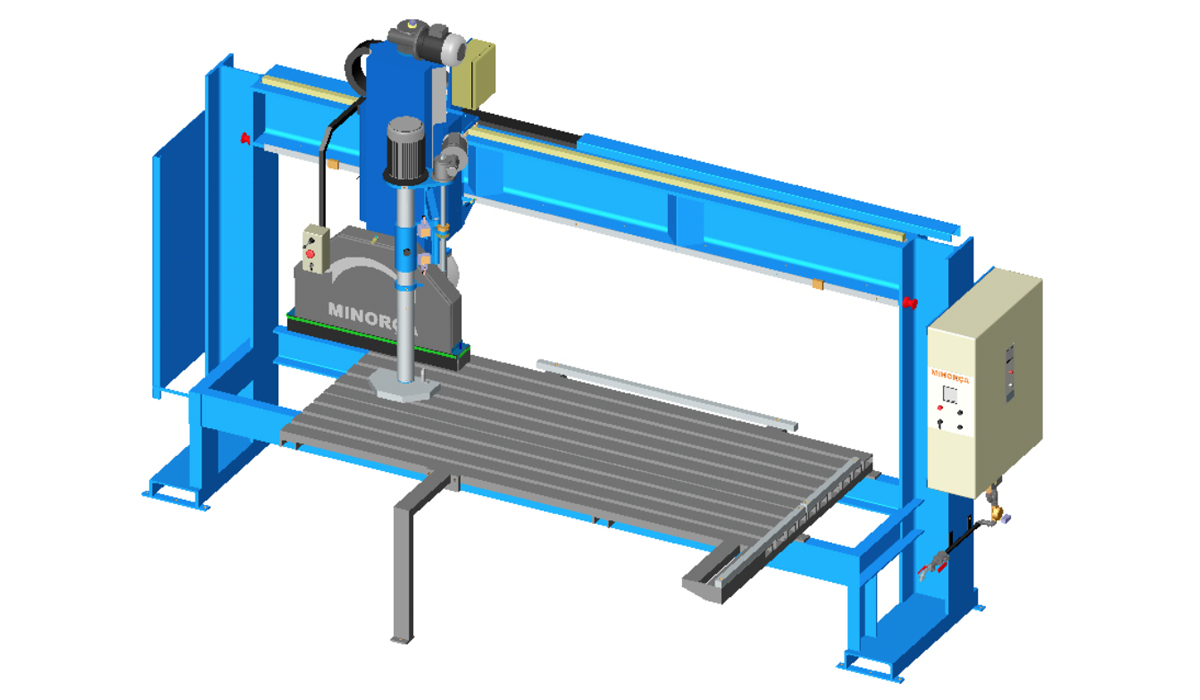

Monoframe Bridge Saw

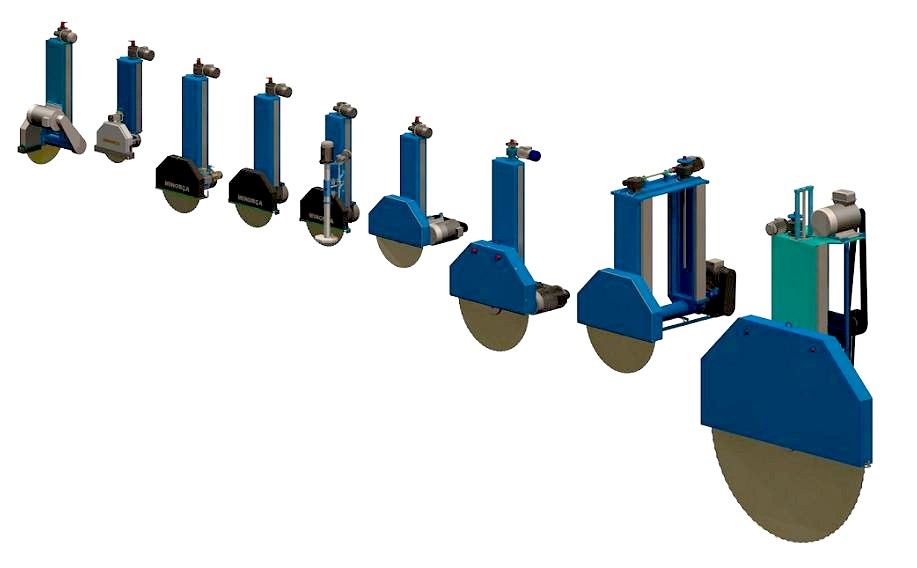

About

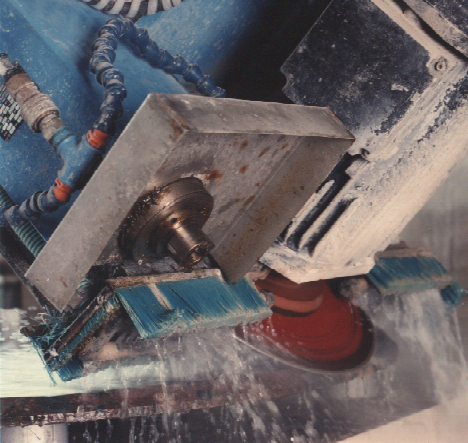

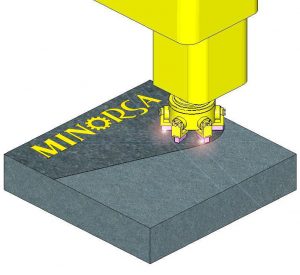

Currently, matching the Hercules Series in its Gamma 300 & 500, presents a concept of application in monobloc structure, that have been implemented by Minorsa, in 1985 with the joint presentation of the use of the rotary head.

It allows the use of a compact structure, where technology is applied for quick movement, and the use of the most advanced software to maximize cutting processes, with precise and solid cutting capacity. Carrying the constant development of the Hercules Series to this integral structure concept.

With capacity to operate the standard material of the market, presents as quick installation solution and potential to be quickly repositioned in order to increase the power of factory layout.

This equipment has several capacities in this concept, from linear cutting to circular cutting.

Technical Features

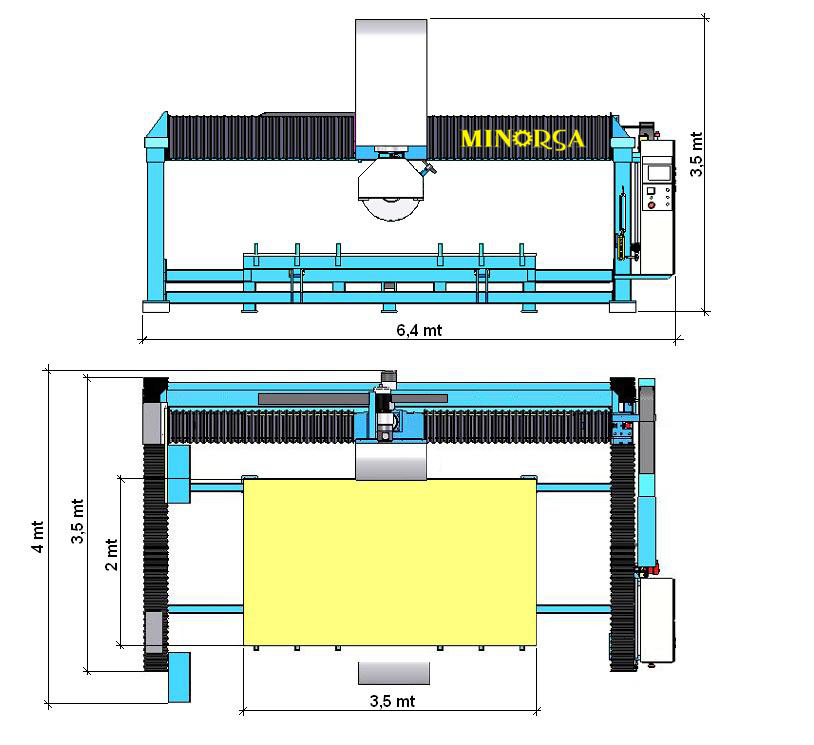

HERCULES SERIES DEVELOPMENT ON 100% MONOBLOC CONCEPT

✓ Diameter of Disc Admitted on Multi-work – 28,1/2 inch ( in ) / 72,5 centimeters ( cm )

✓ Diameter only with Vertical Ability – 43 inch ( in ) / 1,1 meters ( mt )

Multi-work dates:

✓ Maximum Cutting Height – 16,1/2 inch / 42 cm ( Minimum flange support 9,3/4 in / 250 mm )

✓ Regular Vertical Effective Travel – Z axis = 18,5 in / 47 cm ( Maximum 27,1/2 in / 70 cm )

✓ Regular Cutting Capacity on bridge Horizontal Axis = 133,3/4 in / 3,4 mt ( max. 161,1/2 in / 4,1 mt )

✓ Power Admitted on Cutting Motor 15 Kw ( 20 Hp ) / 22 Kw ( 30 Hp )

✓ Approximate Weight – Starting on 13,200 lbs / 6,000 kilos ( kg )

✓ Height Required with rotative head saw – Starting on 141,3/4 / 3,6 mt

✓ Inside distance between lateral rails – from 157,1/2 in / 4 mt (regular: 208,1/2 inch / 5,3 meters) to 236 inch / 6 meters ( using gamma 500 ) 230 inch / 5,84 mt (special size into 20 feet conteiner)

✓ Maximum cutting speed shift – 78,1/2 in / 20 mt by minute or 157,1/2 in / 40 mt by minute

✓ Admitted peripheral speed of the cutting – 20 to 50 mt/sec

✓ Headwaters admitted – regular 118 in / 3 mt , other measure availiable changing the monobloc concept.

✓ Regular monoframes – SAW with head rotation , LATHE with head rotation or round shape , EDGE shape polishing , SINGLE cut saw , dedicated FINISHING work machines

Bridge Saw over Mono Bloc Frame

Two gammas allowing full cutting capacities until 16,1/2 in / 42 cm with top performance over high thickness.

Decide maximum cutting capacity

(all adopted features are common across all ranges)

Direct Flange

8,1/4 in / 22 cm disc 28,1/2 in / 72,5 cm

Pulleys Flange

9 in / 23 cm disc 23,1/2 in / 60 cm

9,5/16 in / 23,7 cm disc 28.1/2 in / 72,5 cm

16,5/8 in / 42 cm disc 43 in / 1,1 mt

Falange on angular box

6,1/4 in / 16 cm disc 23,1/2 in / 60 cm

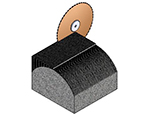

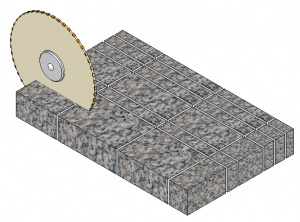

Working Types

|

|

|

|---|---|---|

| Multiple Axes Movement At Same Time

Can make profiles using several axes, depending of the control system it’s possible execute programs generated on cad cam system outside or in proper cad on control machine, the cutting parameters can be changed on machine, the final work quality it’s defined by quantity of cross cut spacement |

Profiling With Horizontal Saw

Can do that in several systems, the most fast and cheaper it’s coordinate the automatic rotation bench supporting above 12tons with the cutting head, can also work with the horizontal saw mixing several axes or milling the stone |

Cutting Execution by Lateral Development

This process can be executed in vertical as well in tilt position, to be a fast cutting can order only one axis cutting movement, much used on primary cleaning or in continued parts |

|

|

|

|---|---|---|

| Vertical and Tilt Cut Until 46 Grades On the ram can execute inclination since vertical at 0° until 46°, allowing the cutting process in several passages without step marks on the stone |

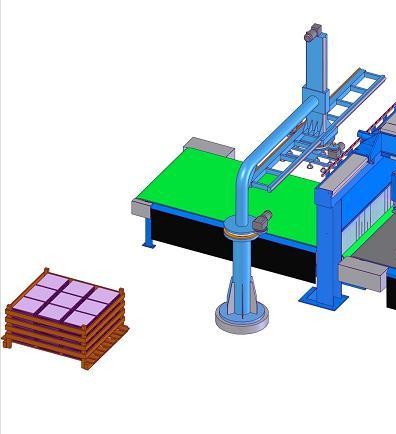

Palletization Process With several bench and robots can improve the shipping process |

Execute 90 Degrees Cutting Angle

In automatic execution can program both cutting sides |

|

|

|

|---|---|---|

| Surface Profiling

With one axe movement each time can produce forms by draw in a proper program on the machine |

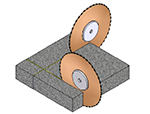

Tilting Saw For Angles Cutting

Theres two systems for angle cutting, the tilt head it’s the most cheaper, rentable and gives perfect finishing, the dual movement of axes can do the process also with the saw inclination axe |

Balustrade And Columns In Round Shape

Can do with proper cad program worked stones in several materials and also forms, like final quality, that one can be perfect, ready to polish |

|

|

|

|---|---|---|

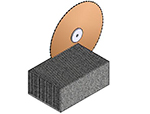

| Vertical Cutting For Slabs Production

Development of proper program to maximum rentability stone cutting |

Work Horizontal And Vertical

The saw can rotate and execute several cuttings on both angles |

Multi-Axis Work Can profile in as the draw |

|

|

|

|---|---|---|

| Saw Round Profile

By proper program can program the diameter, the rope quantity, the proper higher, the final work quality |

Cutting And Cleaning Profiling

After the cutting process the system allows an stone cleaning process with the slow displacement of saw by several movements leaving an final work without stairs |

Automatic Cutting Process in Several Steps also Directions With an proper menu can program the saw work |

|

|

|

|---|---|---|

| Ability to Exchange the Saw Tools By the use of Iso tolls or head change can improve the process to input more cutting cycles |

Movement on Total Oil Bath Ability Improve the time on movement parts and dispense the lubrication check up |

Additional Bench to Be Used On Times Between Main Execution

Improve production with an bench to be used as regular saw work, can be installed on rear or on side of the machine |

|

|

|

|---|---|---|

| Final Polishing Work

After the cutting process it’s possible put the stone in an finishing machine witch can polishing the edges and put it in several shapes |

Primary Polishing Work Starting the material operation with polishing the surface following the cutting process also it’s possible adopt on an proper finishing machine. |

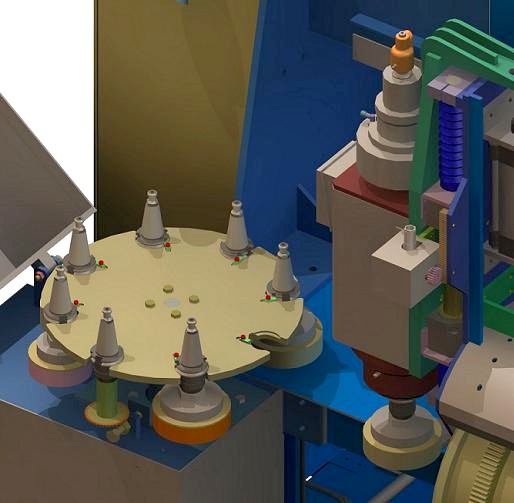

Carrossel Tool Change Provide the work with multi-tools, best to use on spindle |

|

|

|

|---|---|---|

| Head Change Ability Can set several heads on the same RAM allow multiple work on same equipment |

The Hercules Series Over Mono-Bock Frame

Best Optimize on Working Table

For each type of work, we have a more suitable bench solution

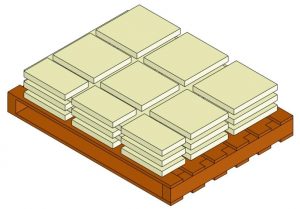

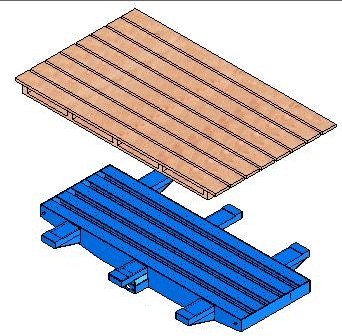

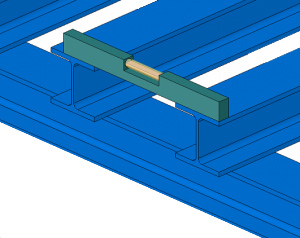

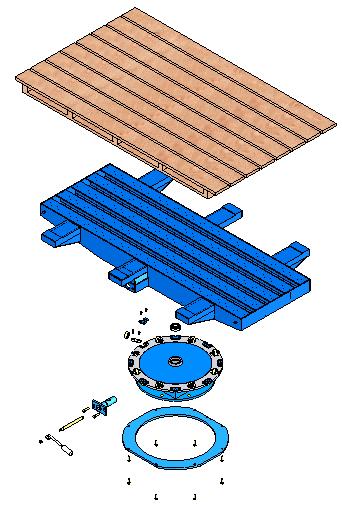

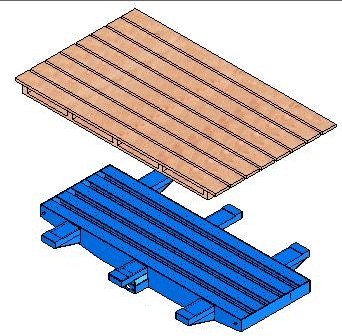

Pine Wood Bench

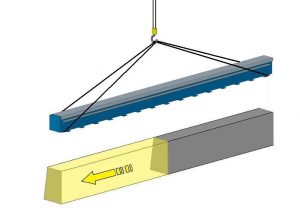

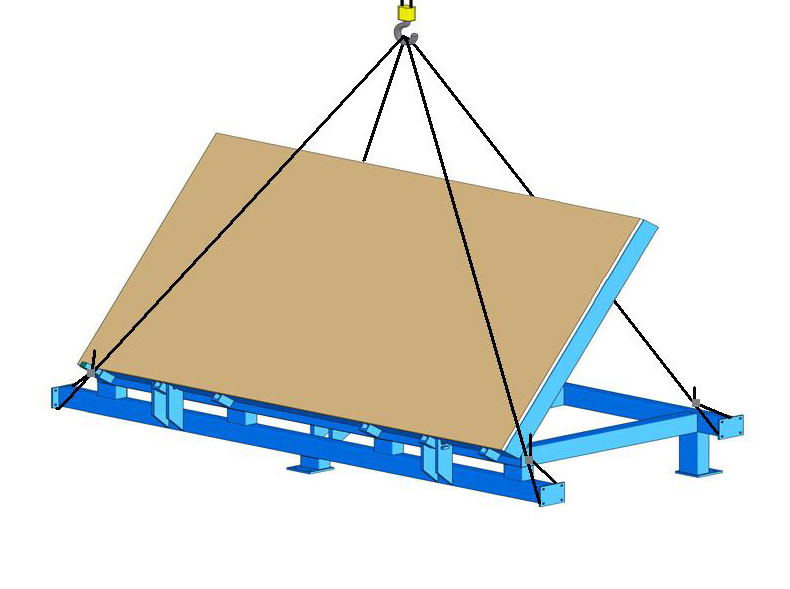

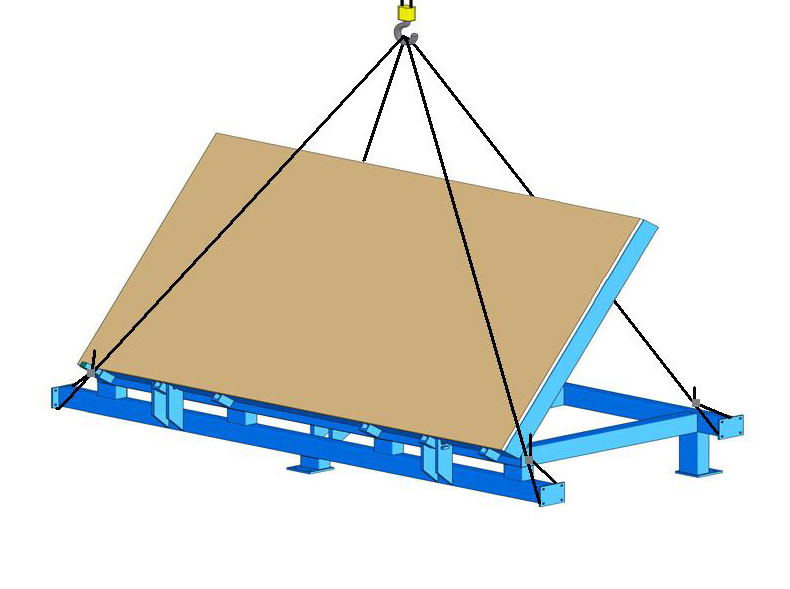

Each Bridge Saw over Mono Bloc Frame will be supplied with an Pine Wood Bench to allow the fast change of working loads, can be moved by an forklift and supports 8,1/4 in / 22 cm of complete slabs, more high must adopt the Exchangeable table with metallic frame.

Size 5,1/2 in 14 cm high and 118 in / 3mt by 70,3/4 in / 1,8 mt

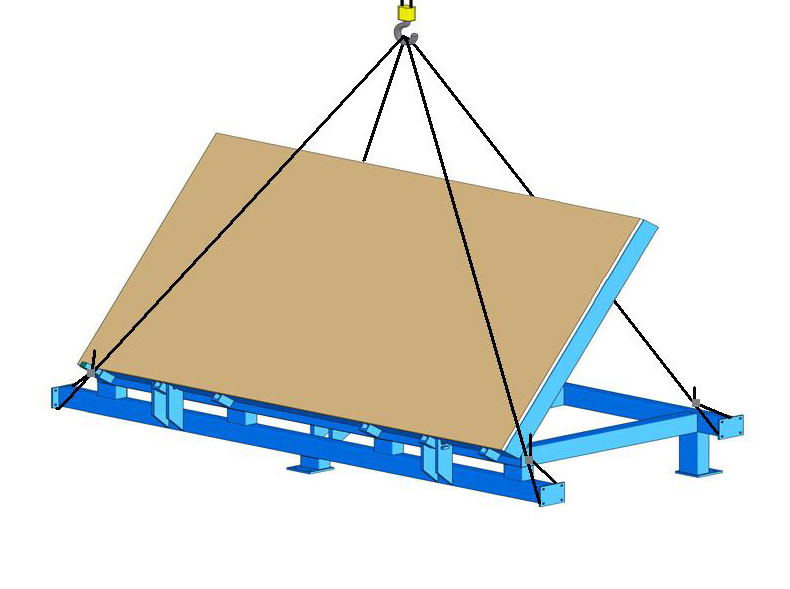

Tilt table for an easy load of slabs

Ideal for bridge crane loading and slab work up to 5cm, it is coated with marine wood, with hydraulic system, and can support weight without twisting. It is also possible to adopt the pneumatic inclination only to receive the slabs. It has an integral frame to allow the exchange for another workbench to work in the same space. The top base dimension starts on 118in / 3m and can be made until 157,1/2in / 4m or more with the hydraulic tilt if necessary.

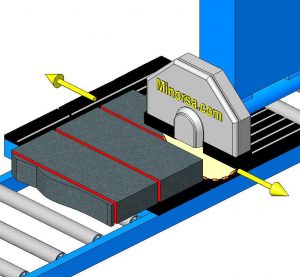

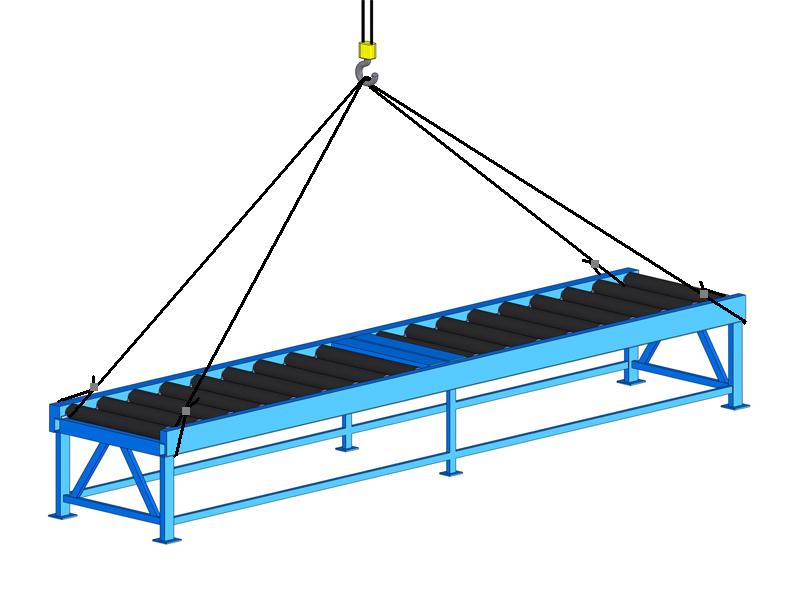

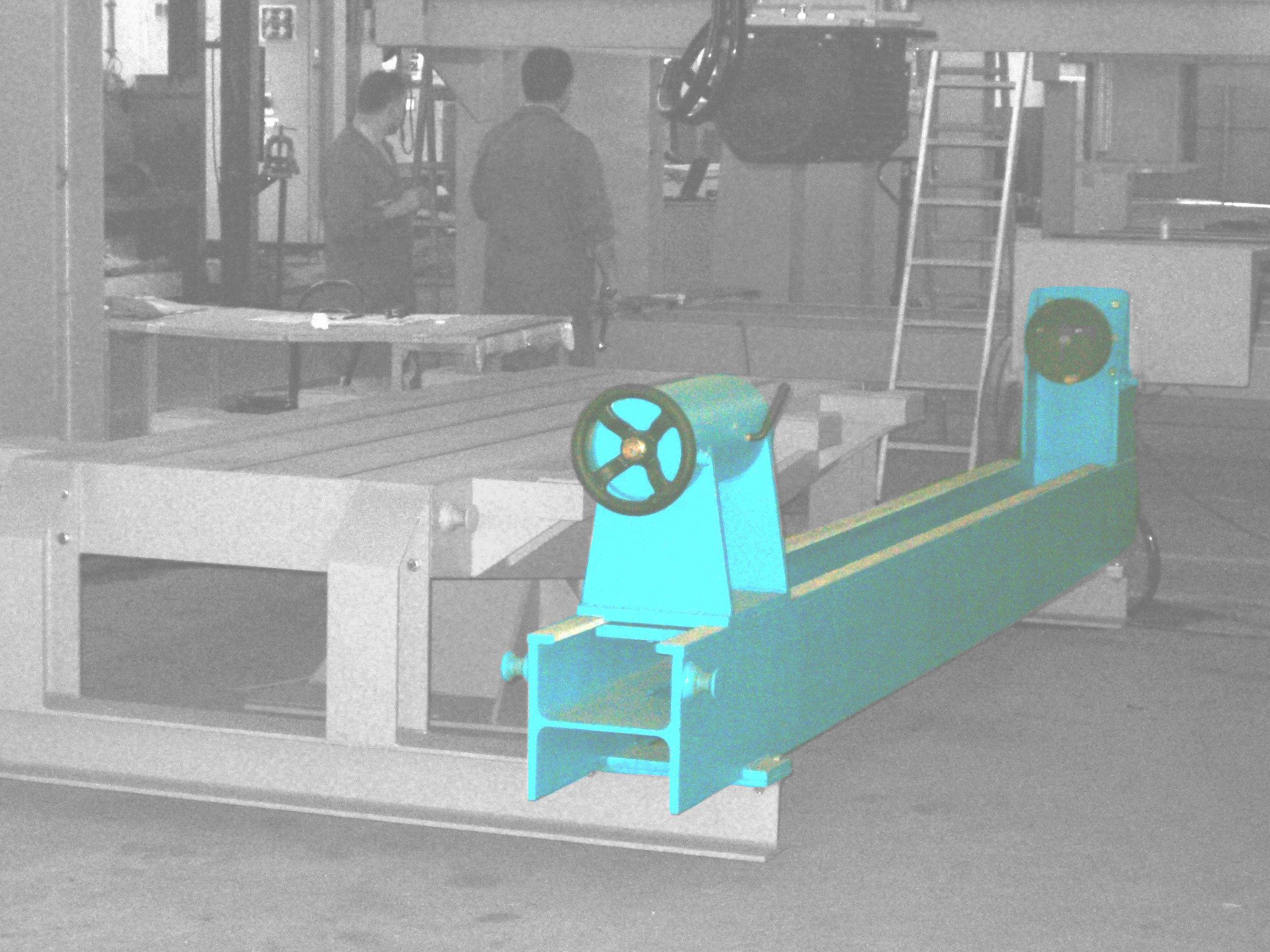

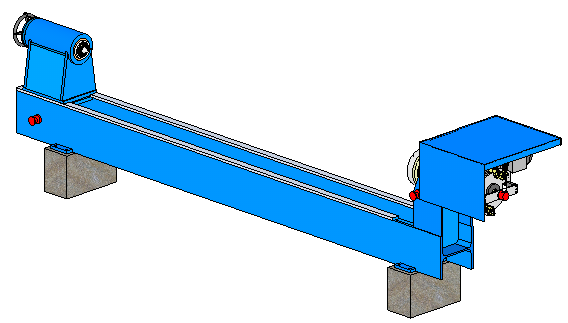

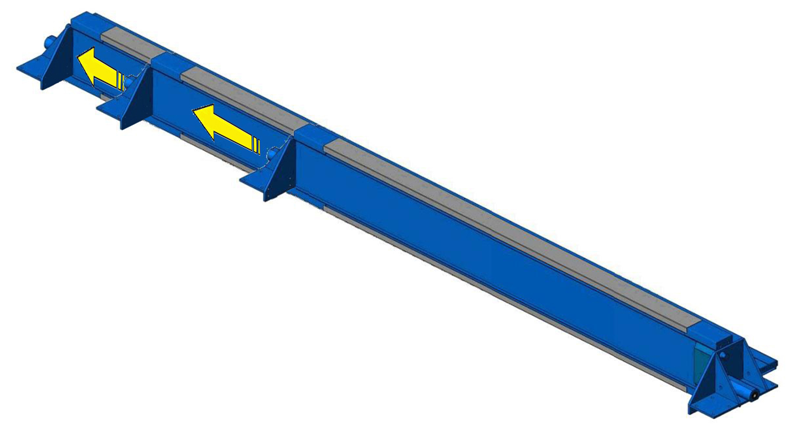

Rollers table for rear unload or cutting on the dead times

This workbench allows the equipment to work non-stop between major jobs, gaining moments of material change. It can be supported by a loading / unloading robot, can use a system to lift the material in the cutting process, and even has several pneumatic pistons to align the material with the saw. Usually it comes with engine rolls. The width starts on 31,1/2 in / 80cm and the standard length is 118 in / 3m plus on main body plus the exit rollers until pallets, those bodies can be made until 236in / 6m and assemble it together.

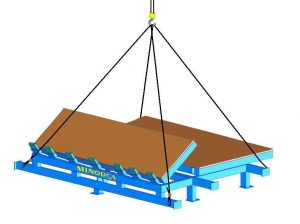

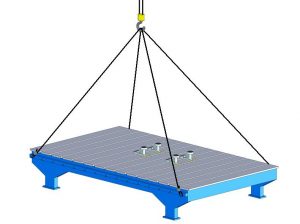

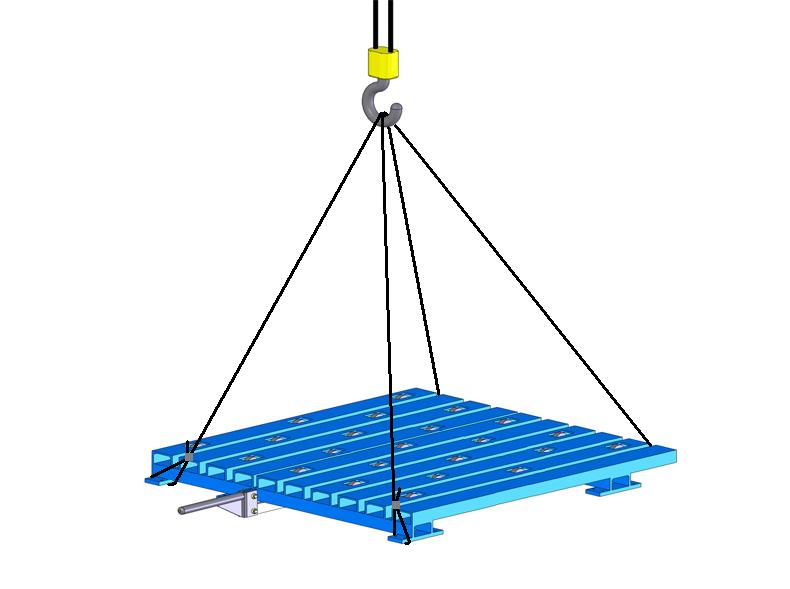

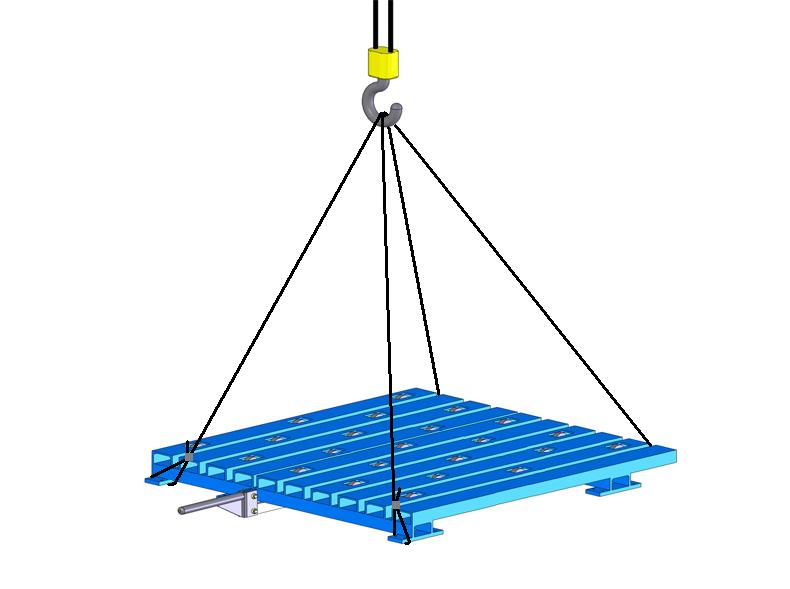

Exchangeable table with metallic frame

This mechanism allows to load several slabs at the same time in the forklift. Its metal frame allows for safe transport, and also with side supports to allow movement by a crane. With this system can increase machine work, have various types of stone or work in process. the top is lined with pine wood, and the regular dimensions are 149,1/2in / 3,8m by 78,1/2in / 2m.

Fixed table for rear cut or stand by materials

A table for working with rare loading/unloading robots that can be assembled with the roller bench carriage. In the case of small parts, the vacuum device will move the slabs, the length will be defined by the bridge, and the upper surface may be with metal frame, with rubber, wood and spinning balls.

Rotate bench to mirror faces

tarts with 51 in / 1,3 mt slab passage to admit the block saw work, can rotate if intend the slab to provide the face to face cutting, electric movement with full inversion of material

1/3 tilt table for high thickness

With this system, load with crane and leave room for more material at work, also the thick slabs will be received by a small table, but with strong elevation.

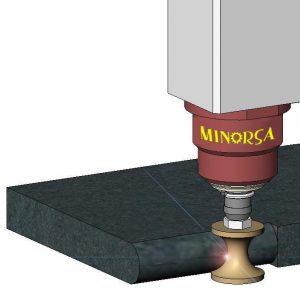

Table with vacuum cups

Made of aluminum or stainless-steel upper surface, depending on whether they will only work with the vacuum cups or receive materials directly on it, the dimensions will be adjusted to the bridge offset.

Fixed table for using with gyratory heads

Great for working with heavy materials, allowing easy forklift loading, and receiving a wooden or metal workbench for processing large materials with less weight or brittleness. The table is fixed and does not rotate and can take the incline system between beams.

Slab movement system with gyratory balls

We have made several accessories to increase the potential of a specific job, such as a simple step-splitting stick or a U-frame for receiving multiple cubes or rustic bands, your idea will work.

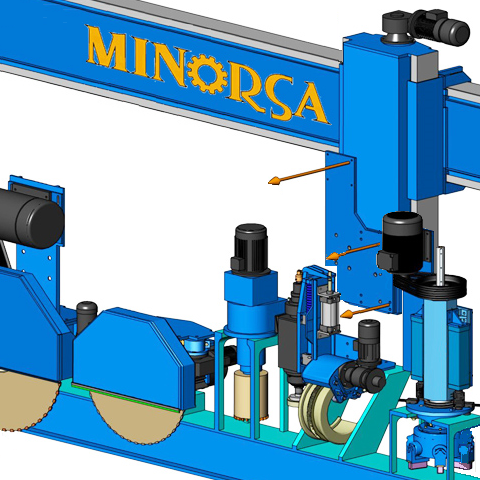

Multi-Purpose Saw Over Monoframe

Suitable for ALL heads IN ONE ram , can cut , polish , drill , edge faces and all more.

Limited into the available space to place the heads, also depending of the vertical travel.

The decision to use multiple heads for multi-operations can be increased even after the equipment is installed. At beginning, it’s provided a RAM with supports ready to receive all exchange program heads. With this mechanism it is intended that the equipment is constantly evolution and adjust to the market requested by customers.

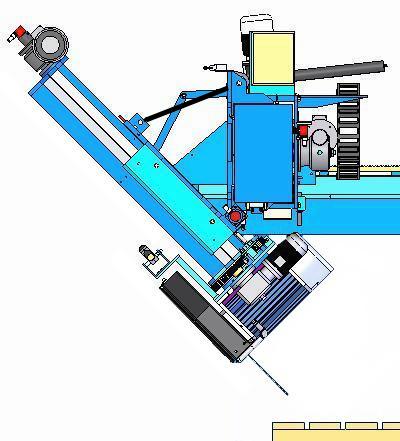

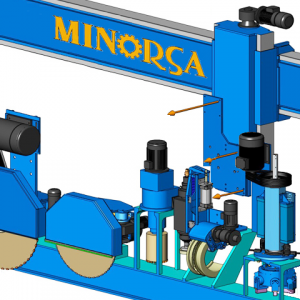

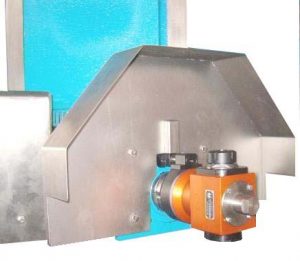

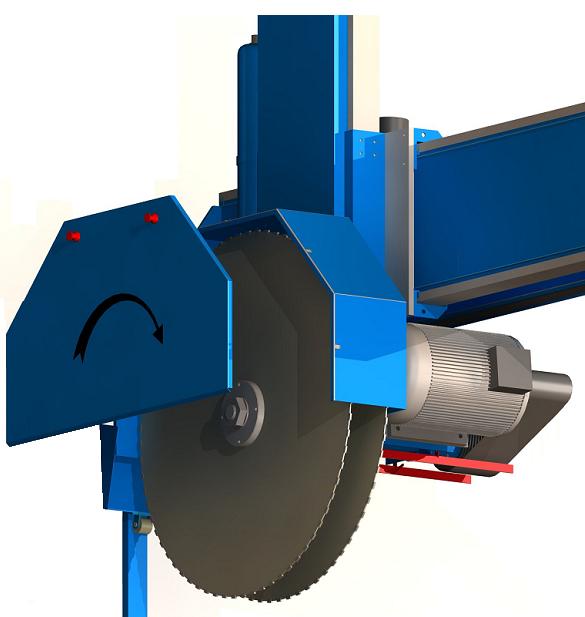

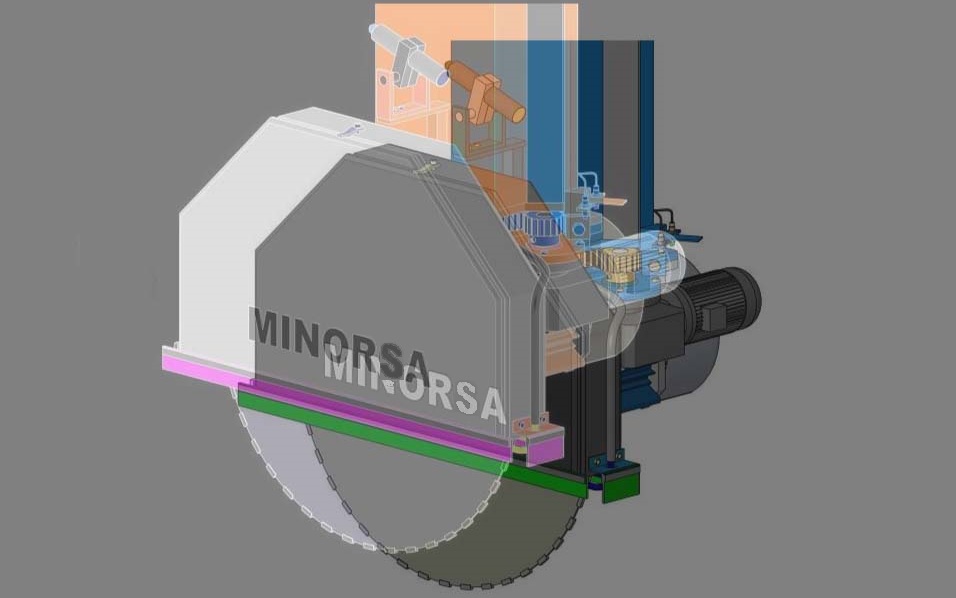

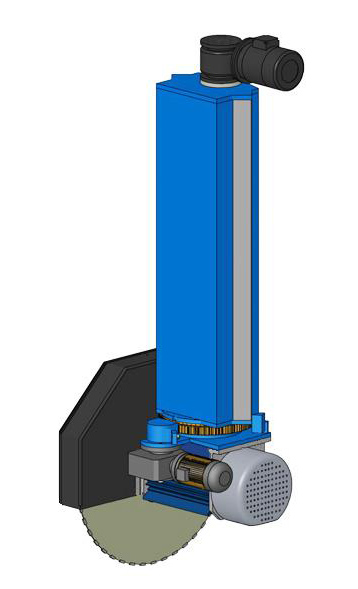

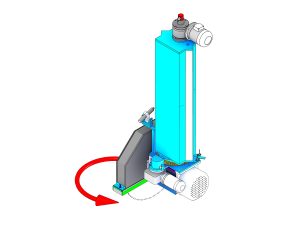

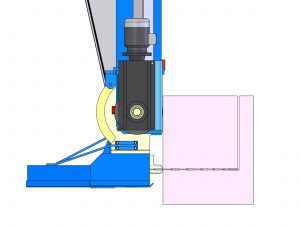

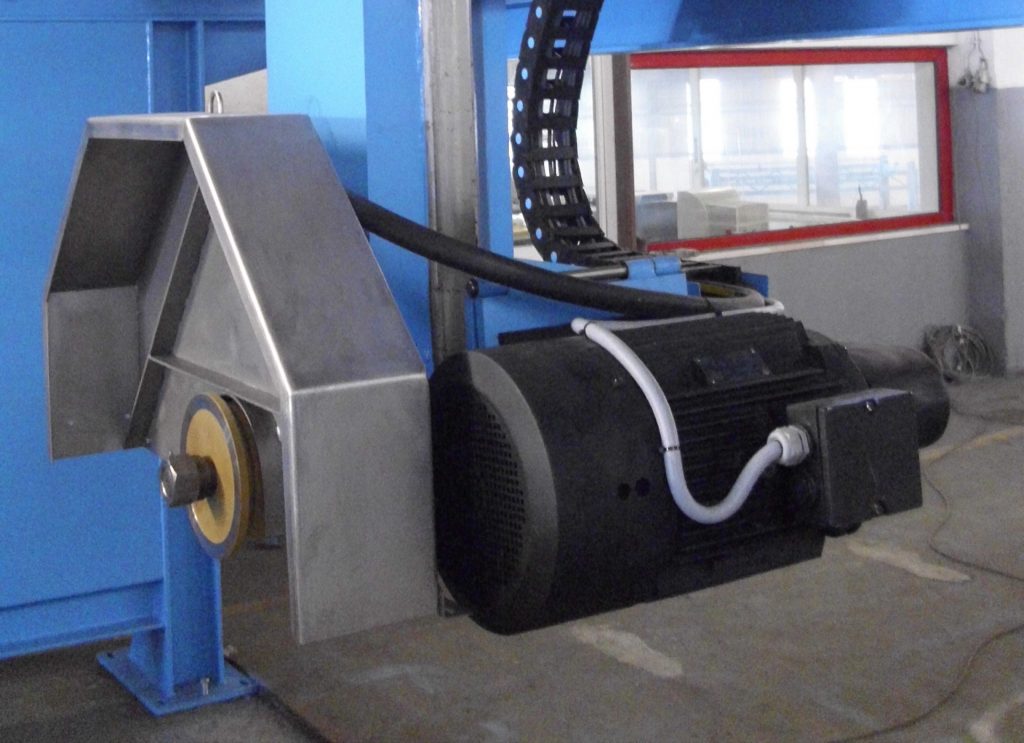

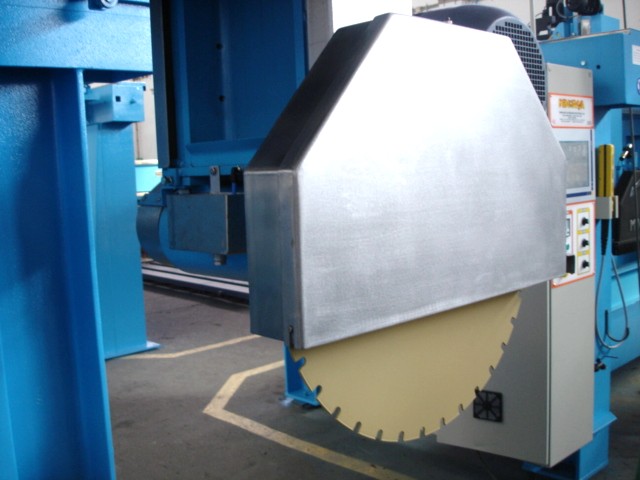

Tilt head until 90º

The maximum disc diameter is 23,1/2 in / 60 cm and is defined by cutting car vertical displacement compensation. The main engine power admitted 15Kw/20Hp or maximum of 33Kw/30Hp. Working on with inverter control at regular 50Hz produces +100% of Power.

The minimum flange support is of 11 in /280 mm and the maximum cutting capacity on vertical saw is of 6,1/4 / 16 cm. The cutting process in maximum disc diameter is by incremental spacing and the blocking of the head position can be selected one of those systems.

By an independent braking system with the angle measure stop each three degrees, and by mechanical stoppers in case of maximum cutting strain required 0/90º.

The tilt head until 90º allows change the total cutting head on cutting head on cutting car and inclination working system on cutting car.

This head solution will be assembled over the gamma 500 bridge

Electric movement; breaking system

This cutting head can be considered as a major assembling the ram. On side supports, on V system or on linear bearings, the choice of mounting is decided by the type of work to realize: for cutting robustness the V-offset system, which allows for a greater constant bearing surface in any position; or for quick and constant repositioning, the linear bearing system. Here the cutting passages will be lower but compensate for rapid positioning or constant movement, in this last case a weight compensator can be applied to aid in the quick reversal of movements. The ease of application and use by the angular cutting system allows the operator to program various cutting cycles on the material without having to move it. With the rotation it can easily dig and with the rotation you can go digging very easily and make roughing cycles in the material that would only be get by repositioning. The robustness of the system lets use large diameter tools, together with the huge power available by a transmission with pulleys where the saw peripheral speed is adjusted, aiming at a maximum cut at 50hz. The mechanical rotation locks allow the user to adjust the maximum cutting power to the tool instead of the accessories. It is designed to perform thick cutting with maximum profitability through the robustness and power available.

It can be used as primary roughing head or for linear cutting on any rock. The intended use of this horizontal ram is able to be multipurpose and have the maximum of robustness. Strokes over the range 500 have an the conditioned diameter, for more diameters see the gamma 500 or 800 on Hercules Series, where the head is larger, as well as the horizontal displacement bridge.

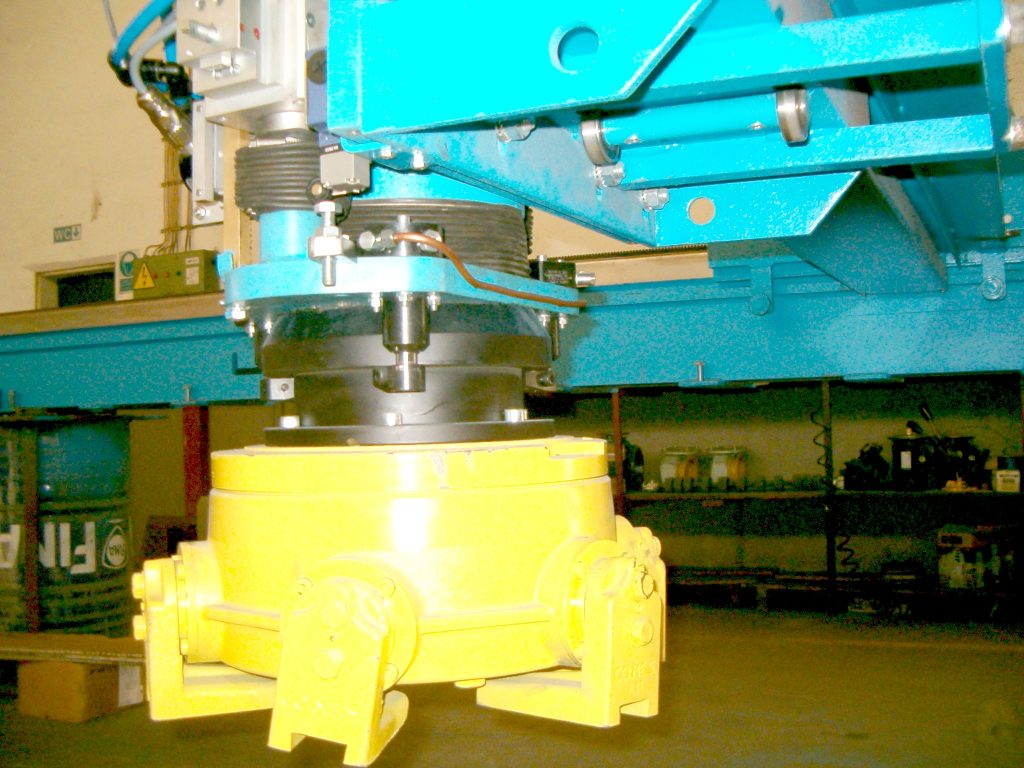

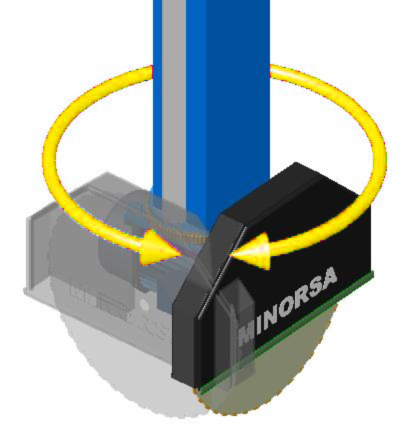

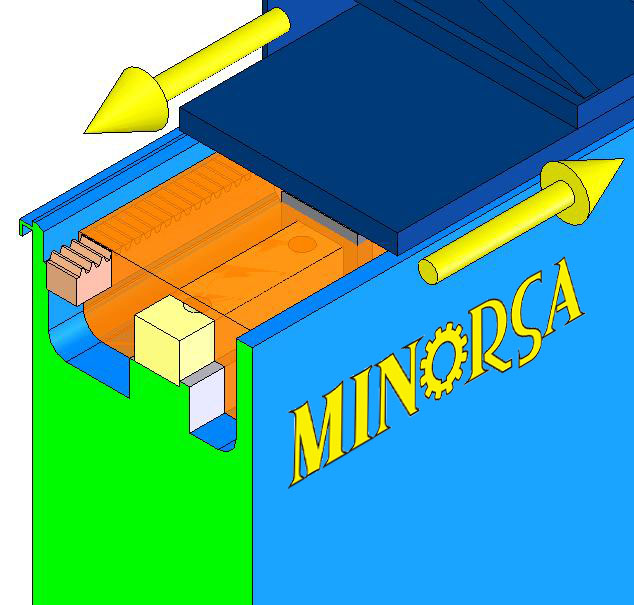

Rotation head 90º with blocking system or 360º with breaking system

Working on with inverter control at regular 50Hz Produces +100% of power

The minimum flange support is 11 in / 280 mm and the maximum cutting capacity on vertical saw is 8,1/3 in/ 22 cm

With this tool you can change the total cutting head on travel RAM, adapt the milling system head on lateral of main engine to drill, also to polishing, multi-head system can work on suplementary bench or in cutting line’s applications, rotatory head and front inclination can be assemble entirety on cutting car.

All used on monoframes, twin rams and all Hercules Series gammas.

Blocking of head position can be selected one of those systems: by an independent breaking system with angle measure stop each 3 degrees or by a mechanical stoppers in case of maximum cutting strain required 0/90º

With this tool you can change the total cutting head on cutting car, adapt the milling system head on lateral of main engine to drill, fixed head working with rotatory bench’s or in cutting line’s applications, rotatory head and inclination working system on cutting car

All used on frames, twin rams and all gama’s.

Certainly, the cutting head with higher forward power. With your engine by direct connection to the saw, that remove torque losses, and the coupled swing system between the ram and the engine, made by a bearing of dimensions exceeding the engine width, we can we can explore the advancement of the saw, limited by diameter to mount and engine revs depending of the material. We have available other heads to be mounted with pulleys, keeping the same principle of rotating crown bearing and the maximum capacity utilization over the saw and not over the equipment, because it is always presented with oversized.

This ram model was designed in 1985 and has always been improved to its yield be as much as possible. It can assemble a mechanical jam system where makes a 0 or 9 degrees positioning. Here, you can load the maximum height with the material and cut with precision and speed (other cutting angles are available using the angularly positioned cutting table). It’s possible select an angled lock swivel system, wherewith get the possibility of cutting in various directions through interpolated movement of axes, limiting cutting feed power to lockout effort. In thick cutting there is an adjustment cycle in the interpolation to smooth out the drag marks made by the disc.

The search of maximum rentability is always on the thick cut objective. With the indication of cutting material, rotations elected to disc mark and characteristics, you can see a productivity historic and indicators that makes the operator get the most out of the head intuitively.

Two axes head with blocking system. Independent of motorization

The maximum disc diameter is of 43.1/4in / 1.100mm and the minimum disc diameter is defined by cutting car vertical displacement compensation. Main engine power admitted 15Kw / 20Hp or Max. 22Kw / 30Hp. If you work on with inverter control at regular 50Hz you can produces +100% of power

Pulleys assemble the mode to allow maximum of power all time on maximum diameter. Assembled with iso attachmentsupports 60% time working (saw flange + iso)

The minimum flange support is 11in / 280 mm with the pulleys system and 10in / 255mm on engine with the flange and iso attachment operate until 6,000 rpm

The maximum cutting capacity on the vertical saw is 12.1/8in / 41cm and cutting process on maximum disc diameter is by incremental spacing.

On this system the blocking of head position is by independent breaking system. With angle measure stop each 3 degrees and mechanical stoppers for rotation in 2/4 rotation plus indexing of 2nd axis by other breaking system (90º)

This tool will allow change the total cutting head on cutting car, increase the head rotation on each angle stop or continuous rotation and increase the head rotation on each angle stop or continuous rotation, by decreasing the working diameter or tool effort

Maximum vertical displacement on tecnical use the gamma 500 bridge , for more until 79 in / 2 mt use gamma 800

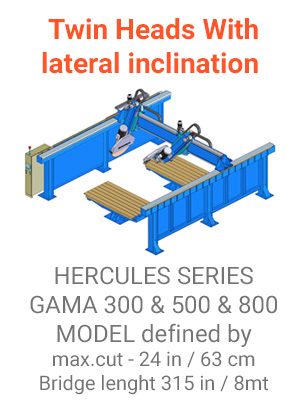

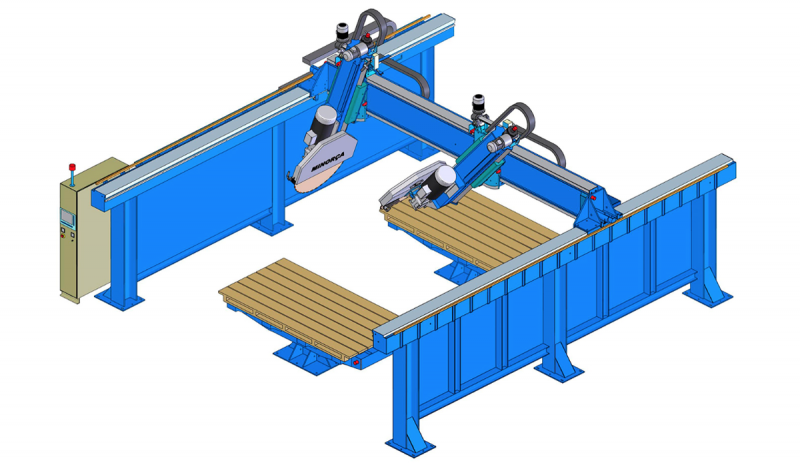

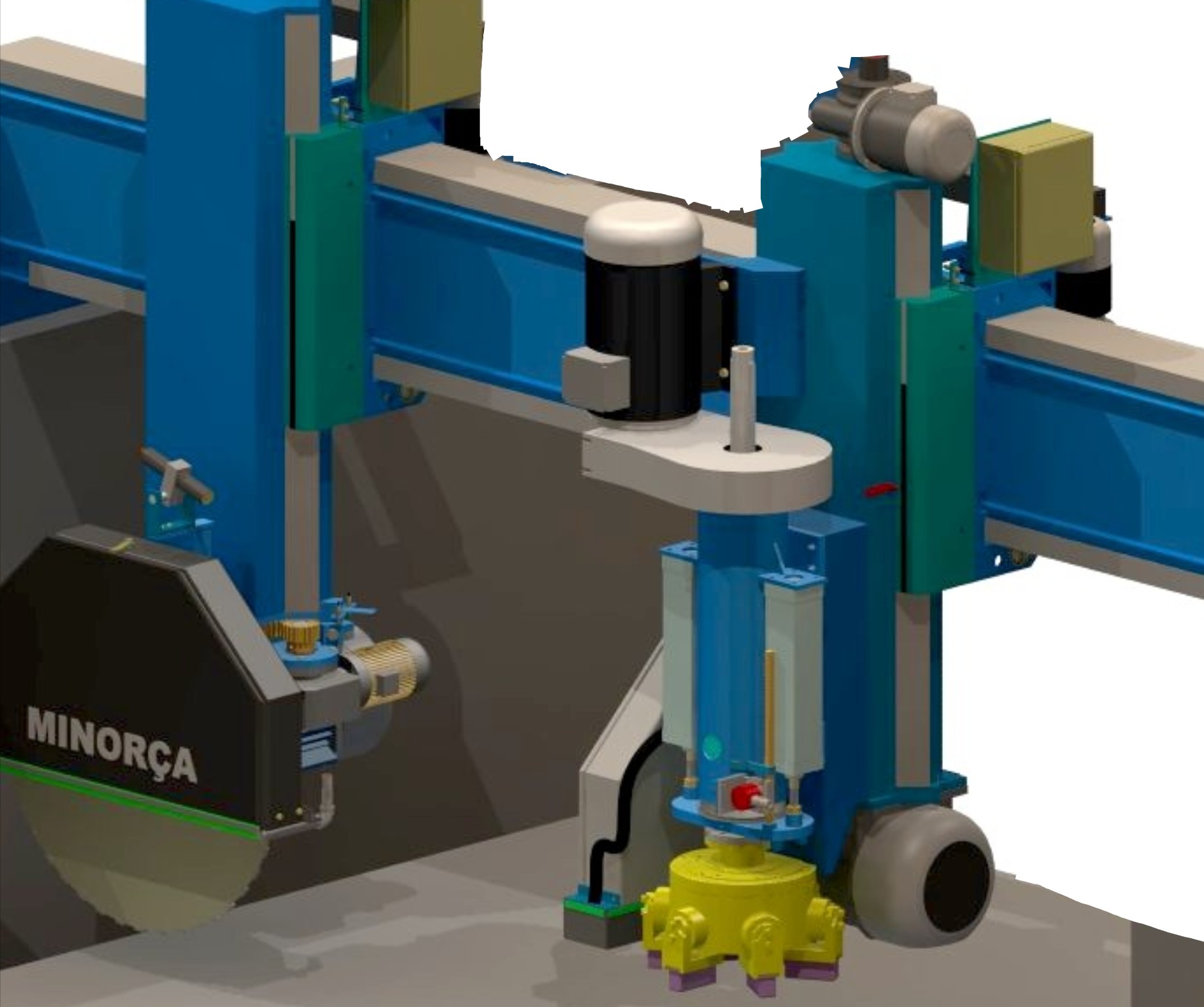

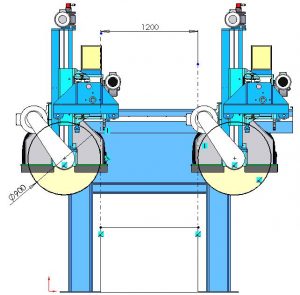

TWIN RAM WORKING SOLUTION WITH MIRROR WORK

For multipurpose use, this cutting head has two positioning axes to can have a huge flexibility. The position lock is mechanical, for use in the thick stone cutting and allow the use of large diameter, being be disable using a motor to control the positioning.

You can mount more than one type of motorization and, also, allows tool change for standard iso system.

The rotation of the shafts is performed on spherical ring bearing system for high load capacity.

Milling system with independent or on multiple head

Tool admissible set by weight depending of the iso attach size. Present a minimum tool length defined by cutting car vertical displacement compensation and the engine power admitted at 8,000 rpm 5.5Kw /7.5Hp until Max. 22Kw / 30Hp. Working on with inverter control at regular 50Hz produces +100% of power and 6,000 rpm with continuous service.

The cutting process on tool working is by incremental spacing or by power and the tool can be change by linear cabinet or in carrousel for small tools

With this is possible adjust the tool above the flange with vertical movement and have nclination working system on cutting car

More vertical displacement and power on gamma 800 until 79 in / 2 mt

An independent working vertical motorization that can be applied in together with other principal engine on same cutting head. With this solution you didn’t need much power, because this male the cutting function with smaller tolls. The operation is conjugate between engines. After disc cutting process, the after disc cutting process engine down and is positioned to complement the scheduled. Also, can be mounted as main, to perform multi-service operations using the automatic tool change.

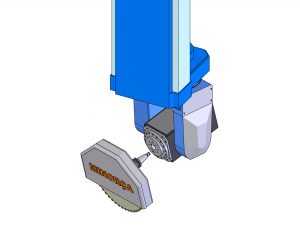

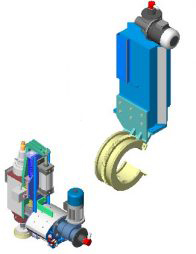

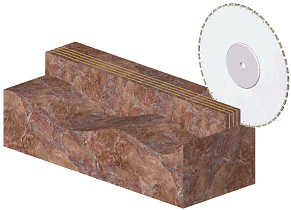

90º angle box for front / rear cutting

Whit a maximum disc diameter 51in /1.300mm and a minimum disc diameter defined by cutting car vertical displacement compensation, this main engine power admitted 15K2 /20Hp, 22Kw / 30Hp or 30Kw/40Hp. This will provide you the best work on granite 22Kw / 30Hp or 30Kw / 40Hp on hard material and the best work on marble and limestone 30Kw / 40Hp above 38m linear. You can also work on inverter control at regular 59Hz produces +100% power

The minimum flange support is of 11in / 280mm and the maximum cutting capacity on a vertical saw is 20in / 51cm. The cutting process on granites is by incremental spacing, and the cutting process in marble, limestone and sandstone is by high incremental spacing

The change the total cutting head on cutting car, lateral inclination until 44º (can be used also with polishing head), use more displacement to cut, using all available space to put more stones, and the possibility to 24/7 saw with the use of multiple heads, are the advantages of this tool.

Also used on gamma 800 with more diameter or displacement, and on twin rams

This ram is the solution for the best optimization of the manufacturing space. With this process will get reduce the return times of the head. Advised to use the largest possible space, enables the constant cutting of complete stone loads. Can be provided a double head, for more rentability. Don’t dismiss the use of other head for most multipurpose functions or be provided with rotating. In this option the diameter is reduced to be placed under the bridge for the displacement of the head.

For mounted the diameter is provided the ‘gama 800’ where the head also has greater robustness.

Carousel tool change / linear head change

This system support 8 tools and are available for iso cone size 40 or 50. The distance between tools more than 6in / 15cm. It is indicated for fast tool change (like polishing and drilling operation). The process of changing cutting head allows monetize the maximum or the equipment. With the suitable choice of the head by type of work, you can use it on maximum power and efficiency. Embrace specifics solutions by works without forcing an engine to multipurpose use. Through tool change, you also can make all the needs for work on the rocks.

Head polishing system

Can execute top face polishing in high trickiness, and a diameter of the plates permissible – 120mm, with maximum thickness height of 120mm. Designed for thick polishing, it was removed from the top polishing equipment in order to monetize the equipment, making it multipurpose and with potential to perform the works with the required power and structure, for a perfect granite finish. The equipment has specific programming screens to configure the polishing cycles.

Piping drilling

– This head can be used to core drill / Hollow drill on high diameters

– The vertical length will be conditioned with the head displacement

– The power can be defined as the intend

– To can make a great drilling it’s needed to have low rotation with a lot of power. This specific head makes its hole cycles on automatic mode, being able to work after hours, changing the hole, and controlling the effort on the tool. It is the suitable to make big diameters holes, because its extreme dimension support underpinned on positioning bridge.

Multi-system with cut and polishing

Check the details bellow on Polishing Head

Polishing head with an oscillation receives 5 Fickert attachment, pneumatic controlled pression and internal specific programming with proper polishing cycles. It allows assemble with a gyratory cutting head on the same ram.

More vertical displacement on gamma 800

Mounts a surface polishing head together with a cutting group, allows for the optimization of material placement, making the surface finishing and then the cutting process.

You can mount with the spinning disk option or operating on turntable.

It has suitable screens to optimize the polishing process in conjunction with cutting screens.

In this solution it is not possible to change the heads, but the head can be lowered to interpolate the service.

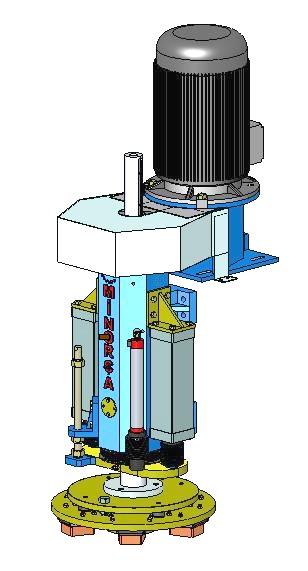

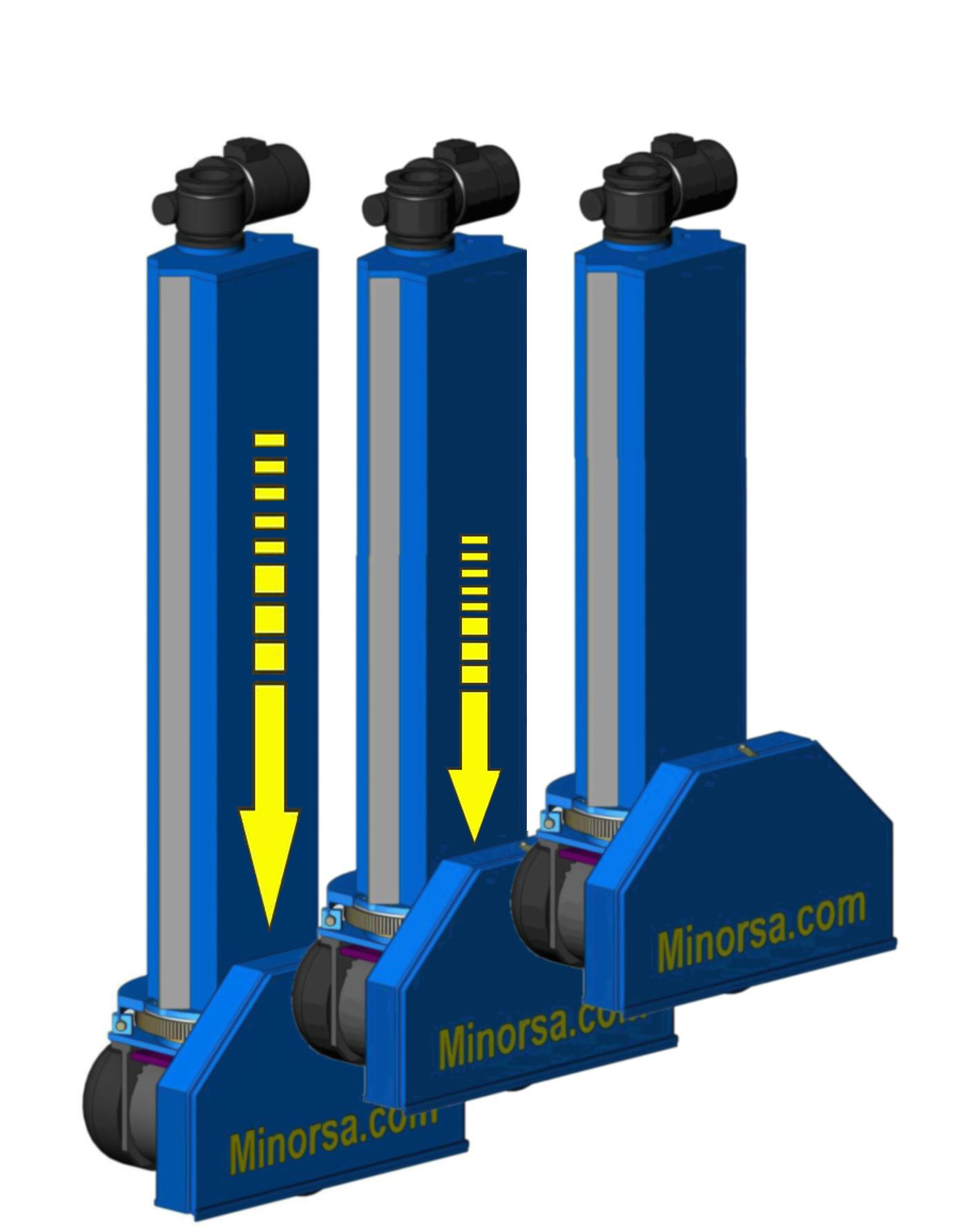

Gyratory with independent motorization

With a maximum disc diameter of 43 in / 1,1 mt and a minimum disc diameter defined by cutting car vertical displacement compensation this tool has a main engine that admitted 15 Kw ( 20 Hp ) or 22 Kw ( 30 Hp ) of power.

You can get the best work on granite by 22 Kw motor with pulies system on hard material, and also the best work on marble and limestone by 30 Kw / 40 Hp on special assemble & config. Working on with inverter control at regular 50Hz it allows produce +100% of power.

The minimum flange support is of 9.3/4in / 250mm or 11in / 280mm and the maximum cutting capacity on vertical saw is of 16,1/2 in / 42 cm

Change the total cutting head on travel RAM, front inclination until 46º (not be used on multi head assemble like saw & polishing), allow a 24/7 saw with the use of multiple heads and cut in 90º with stoppers or with the breaking system can stop in each degree, are everything you can get with this tool.

Also used on gamma 800 with more diameter or displacement and on twin rams

This cutting head solution lets operate with large diameters, getting adjust the rotations and keep the binary to the cut. The ram is designed for automatic use and allows switching with another for full-featured equipment functionality. The rotation system is oversized and can be assembled with mechanical lock or stop at various degrees. For highest performance and maximum power, use mechanical lock. When you need to index at a specific angle, use axis interpolation.

Iso system for tool adapting or accessories

Central cutting saw for an easy positioning by cnc system

Technical Features

✓ Diameter of the disc permissible – 450 mm to 725 mm (900 mm)

✓ Maximum cutting height – 220 mm (Falange 280 mm)

✓ Power of main motor – 15kw (20hp) / 30Amp. ( 22Kw (30Hp)

✓ Minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

Horizontal disk

The horizontal disc can have an vertical positioning by electric motor

By the use of stop switch with an proper command move between them.

The start cutting deep is 5 in / 13 cm with disc 15,1/2 in / 40 cm

Can cut with saw until 43.1/4 in / 1.1 mt using the polished system

Or an high revolution engine power at 8,000 rpm 5.5 Kw / 7.5 Hp

until Max. 22 Kw / 30 Hp (in this case will allow more working tasks)

Polishing head

DIAMETER OF TOTAL PLATE (INCH (in) / MILLIMETERS (mm)) 20 in / 510 mm

DIAMETER OF DIAMOND HEAD TO CALIBRATE 17.5/8 in / 450 mm

LESS PLATE DIAMETER AVALIABLE BY THE USE OF PLATE WITHOUT ATTACHMENT

MAIN MOTOR POWER ADMITTED 15 Kw / 20 Hp or MAX. 22 Kw / 30 Hp

WORKING ON WITH INVERTER CONTROL AT REGULAR 50 Hz PRODUCES +100% OF POWER

PULIES ASSEMBLE MODE TO ALLOW MAXIMUM POWER ALL TIME on defined material

POLISHING HEAD WITH OSCILATION recive 6 FIKERT attachment

PNEUMATIC CONTROLLED PRESSION

INTERNAL SPECIFIC PROGRAMATION WITH PROPER POLISHING CYCLES

ALLOW:

CHANGE THE TOTAL POLISHING HEAD ON CUTTING CAR

LATERAL INCLINATION TO POLISHING PIPES (same used on 90° angle box)

TWIN RAMS WITH POLISHING HEADS (making mirror work)

MORE VERTICAL DISPLACEMENT ON GAMA 800

TWIN RAM WORKING SOLUTION WITH MIRROR WORK

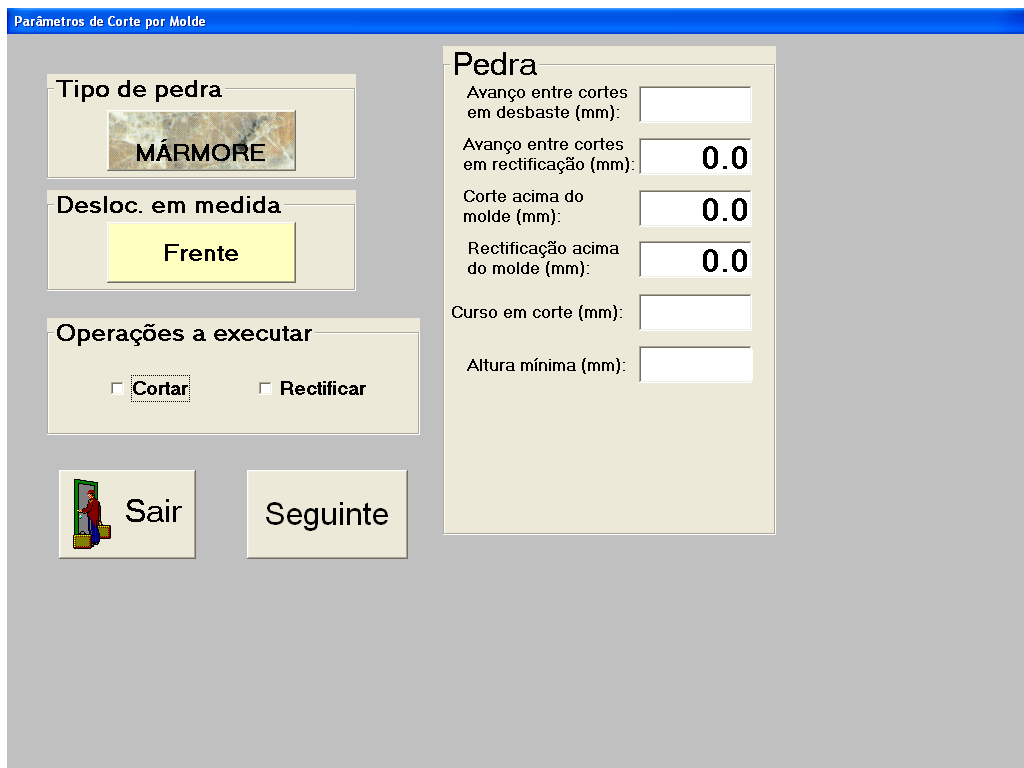

A Solid Program with Single-Service and Pre-Forms Concept

With the internal use of cad system, machines can cut surfaces without external resources.

Defined the spacing between cuts

The distance limits, as the distance of the vertical cut in a protrusion (avoiding premature material removal) and the distance between cuts (as a way to speed up the process or improve the preparation for the final cleaning), are defined on the base drawing. This is something that can only be obtained in specific programs for the execution of stonework.

Can draw lines and arcs also ellipses

It’s possible make parameter adjustments, copy parts to add, delete zones, modify only a area, mirror, and work on a square grid.

Set all auto mode

Several functions are available to define how you want to do the job, as the cut distance above the knee or the cleaning distance above the drawing. It’s possible select cuts in double way, adjusting the performance to the material hardness. You can return a work that has been interrupted by a power failure.

Pre-view of cutting operation

With this view where a faster roughing operation can be performed, it’s possible make the cut simulation, and check where it will concern on the final, and can change the cut location to leave no defect in the finishing zone. It makes zoom, view the work in full view and shows the final finishing line.

3D view and extreme precision on final work

There is a simulator to view the work final aspect, and is very useful to show the final product to the client. The execution of the drawing can be performed in any position, with the simple the simple definition of the cutoff point and the operation can be multiplied. Also, the linear offset of cut is defined. All in order to maximize the available cutting area.

Final Work of granite cornice

An internal drawing program designed to be operated with great simplicity and that ensures most of the works, leaving the user to parameterize several variables in order to ensure the final quality and increase productivity. It’s possible make fast thinning as time optimizer followed by thinning to the desired height and with the final cleaning cut adjustment by close passages to the final product, ready to receive the surface finish.

The program claim is allowed operator without specific expertise on cad cam operate the equipment, leaving the option of more elaborate programs to be received by wi-fi or pen drive and operated by cycles in automatic execution.

Dual Tilt System Allow an Unlimited Work

On Both Tilt’s Can execute From Deep to the Top. Horizontal cut position, allow automatic cycles and several disk diameter, with an rotating bench can make an fountain.

Head tilt until 90º

The cutting head with tilt option, can execute the cutting process in several degrees. Locking system is mechanical to allow high saw diameters. You can also adopt a breaker system to work with more angle options. In this case, the increase in power in the saw will decrease with the effort.

Total ram inclination until 45º

Automatic spindle tilting system, programmable for angles from 0 to 46º, allowing cuts in granite with excellent finish (only available for equipment with saws up 28,1/2 in / 72,5 cm , more on gamma 500 up to 43 in / 1,1 mt diameter, more diameter chose gamma 800.

Allows mitre joint cut since vertical until 46 degrees with several cutting cycles, no scar the stone.

Several Potential Allowing Extreme Final Works

With the constant intention of equipment to make the most of it, its development has the polyvalence of can be adapted with the factory needs. To fit in with the constant evolution of the market we have developed several separate accessories that can adapted, (depending of the frame base) in order to keep the equipment at its maximum performance. It is designed for a for full non-stop operation and maximum utilization of both installed capacity and working time. Therefore, whenever you are on hold you can do lengthy or for stock.

Exist the option of add more length on lateral travel rails, that will allow an rear bench, roller table, lathe assemble to support material to be cut in several stages, because the equipment has the ability to pause this operation for direct operation and operator intervention will be possible use the time between main work. Through multi-heads you can consider multi-operations, the same surface polishing, rear bench use to edge polishing or production of colunes.

Must consider the Hi-Tech Combi Bridge Saw with continuous rubber rug model.

Roller system to cutting stripes

Provides the output of cut stone or can increase production downtime by cutting feed strips. The dimensions and the rollers weight capacity can be defined as you intend. 31,1/2 in. / 80 cm ; 63 in. / 1,6 mt. ; 78,1/2 in. / 2mt. and 86,1/2 in. / 2,2 mt. For example, to polish strips, you can order a vacuum autoloader that is inserted above the rollers, and after the process is complete, remove it and insert another stone.

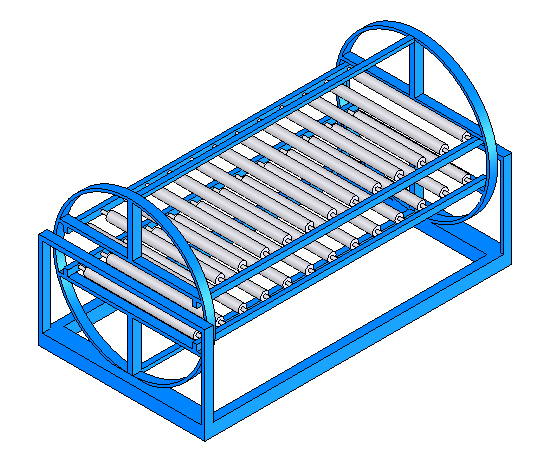

Rotating axis (lathe work with blocking system)

Can produce rounds, squares and other shapes. The regular dimensions are 118 in / 3 mt long with ability to work 19,1/2 in / 50 cm from a square shape (aprox.70 cm between corners), the best is use all capacity on travel RAM assemble an rear optimization or divide the rear space by an bench plus the lathe. We have available the lathe body until 394 in / 10 mt between supports on granite columns with two cutting heads, since 1982. To use on gamma 800 Hercules Series.

In complex jobs, you can apply a double branch to duplicate the process. The finishing work is completely clean and ready for surface treatment.

With a breaker system and an angle measuring system that can block all possibilities of allowing the saw to work, the entire body of the mechanism is removable and can be mounted on a concrete base or on a suitable worktable. The saw can work this way on many sides.

The switchboard can be mounted under the mechanism and can be autonomously transformed to perform other tasks manually or to insert it into multiple machines.

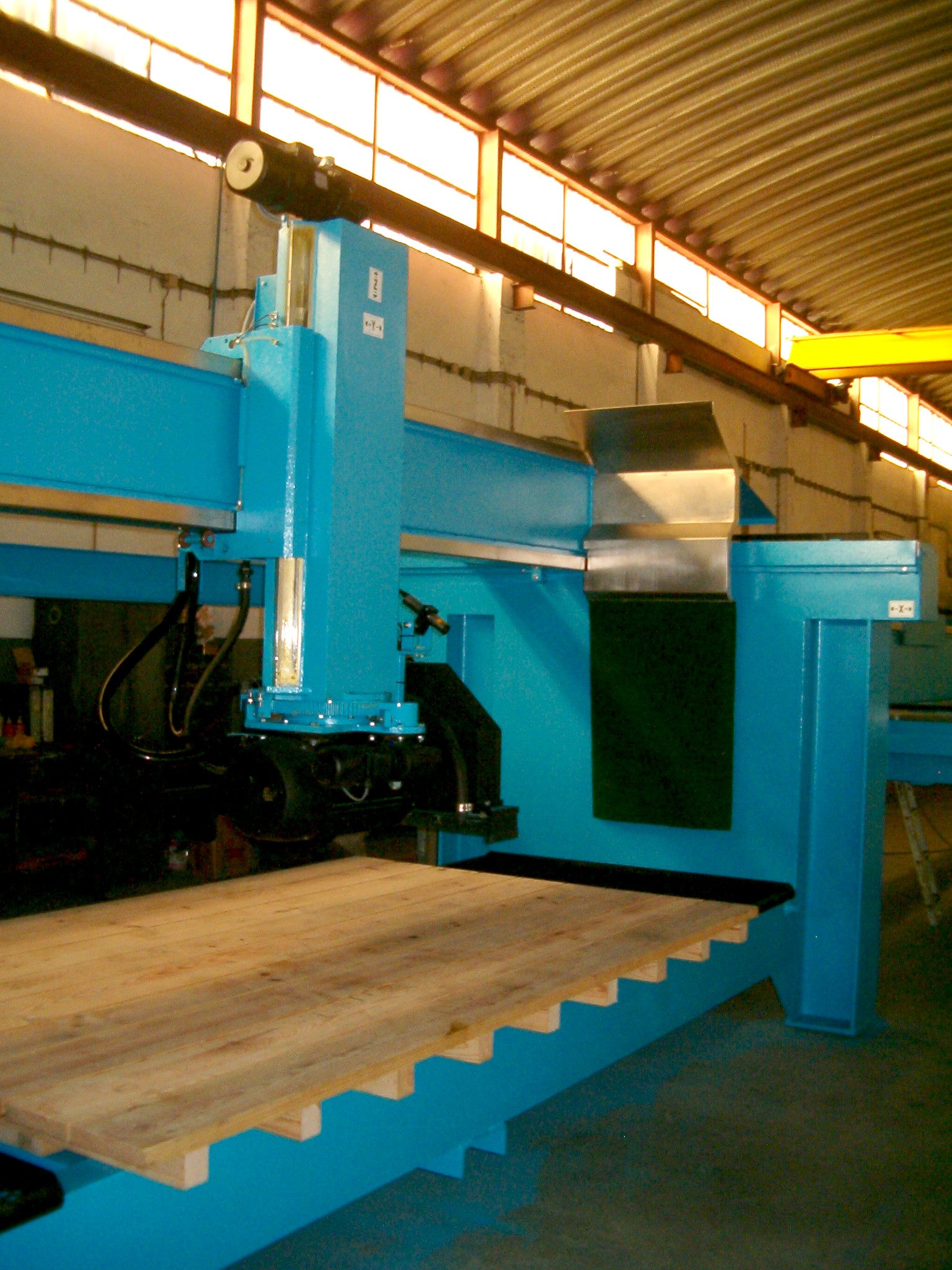

20 meters of table with 2 bridge working machines with rotation head

The maximum length we produce is 787,1/2in / 20m. It should be enough to transform the equipment with versatility, earn with the work and install the concept of multiple tasks. In this case, 2 rotating-head bridges process granite beams on a concrete-based pine wood table. In this case, while two rotating-head bridges process granite beams on a concrete-based pinewood table, the same saw calibrates them. Depending on the intention of increasing production, the material can be entered from the sides into rotating moving tables and work with two rams on a bridge or assemble several heads.

To adopt this solution must check the gammas 300 , 500 or 800 about the bridge length and the use of pre build concrete pillars.

Double working bench

With this setting can move the bridge over entire displacement rail and turn the both tables in a long journey. The work is programmed in separate for each table and can redefine it without stop the working saw process. The choose option of double bench can be by different types and don’t need to be on twin way.

To adopt this solution must check the gammas 300 , 500 or 800 about the lateral rails and the use of pre build concrete pillars, also can assemble it over lateral metallic pillars.

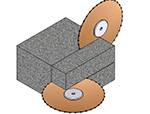

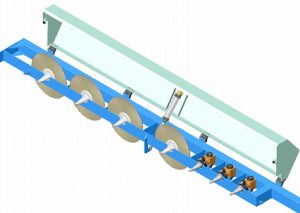

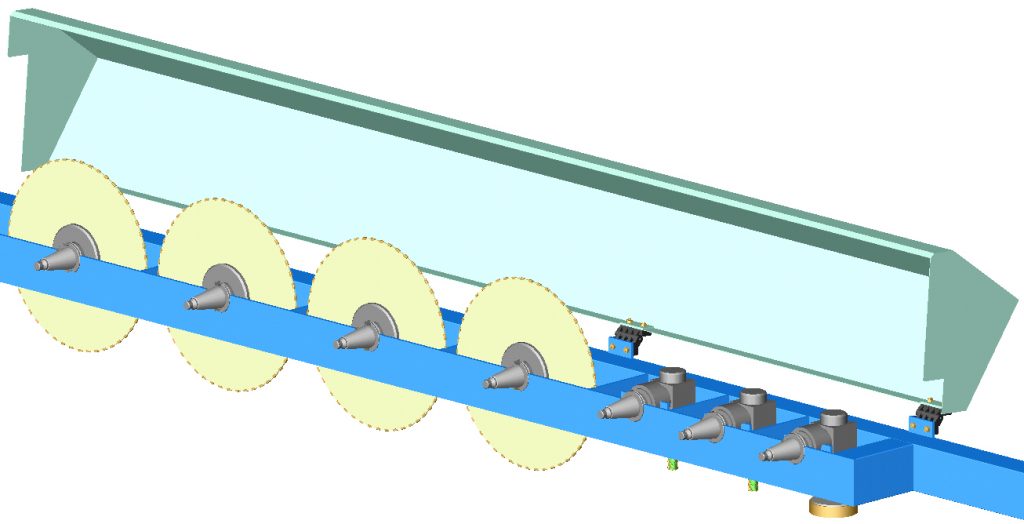

Multi disc assemble

With a long and reinforced shaft, you can mount 3 or 4 discs, depending of the diameter and main power.

To adopt this solution must check the gammas 500 or 800 about the potential to use more main power and the use of pre build concrete pillars, also can assemble it over lateral metallic pillars.

Multi service & multihead

The developed ram allows assemble multiple heads, that don’t need to work at same time but are assembled to complement the process. One will be the main head and the other can be ready to work as desired by changing the positioning. The main disk is lock on the top, but when down it will work on regular way. It can be for sawing, high-speed drilling, polishing, vacuum or clamp lift or to adjust another cutting body with wire saw or chain saw or moving bridge to move the stones. Depending the intent, you can change heads on moving bridge, you can work with multiple accessories on the bridge rail and can support multiple bridge systems to compliment itself. There are many options focused on increasing production, which can likewise work with multiple systems, offering multiple tasks, complementing the process or multiplying production.

The advantages of this tool include multiple identical heads on same the bridge, different heads on bridge, dual heads on one head, multiple head on multiple bridges and different tasks with several bridges.

For Details check information on Option Dedicated to Multi-Services on machines main menu.

Stripes cutting with horizontal disc

The two saw ram heads on the same bridge let you remove the streaks with a quick and easy process. You can decide the type of printhead to be mounted as a supplementary job on ram, as the polishing, drilling or others, as described in the appropriate menu.

Two working Rams with multi-heads

The two saw Ram heads on the same bridge let you remove the streaks with a quick and easy process. You can decide the type of printhead to be mounted as a supplementary job on Ram, as the polishing, drilling or others, as described in the appropriate menu.

On regular production an bridge machine with 2 heads over an Ram, witch can be one with cutting component and the other (right side) with polishing component or both in one.

The command will be on same screen with touch function and all programmation of cutting with saw or polishing with 6 abrasives are full automatic with the able to work all kind of stones (since hard granites to marbles or limestones also) the main attention it’s because the machine will be prepared normally to granite, in soft stones the main motor will not have enough power for an single cut in high thickness (have to be done as the granite, by several cutting steps)

Or if preferred it will assembling more power on motor and on that way will be prepared for soft stones and have to reduce the saw diameter for granite.

Multi disc on bridge

To increase the cutting capacity over set distances, you can mount multiple saws on the same body, which will allow an entire axis to insert the discs. These will be powered by a main engine with belt system to transmit the correct rotations. This system can be mounted on gamma 500 bridge or gamma 800 bridge, or on double concept bridge, depending on the intention. The start on gamma 500 is 19,1/2 in / 500 mm with 40Hp / 30Kw and maximum on gamma 800 is 125 Hp / 90 Kw or up to 220 Hp /160 Kw on double bridge or this gamma depending of discs quantity.

The workbench can be made with options to increase work progress through a separate attachment or a suitable workbench, as the ball system easily moves the slots or parts of it to the entire pine-wood bench.

Vacuum accessories, rotation systems, forklift loading space and more are presented in the Working Bench menu.

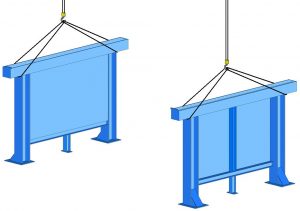

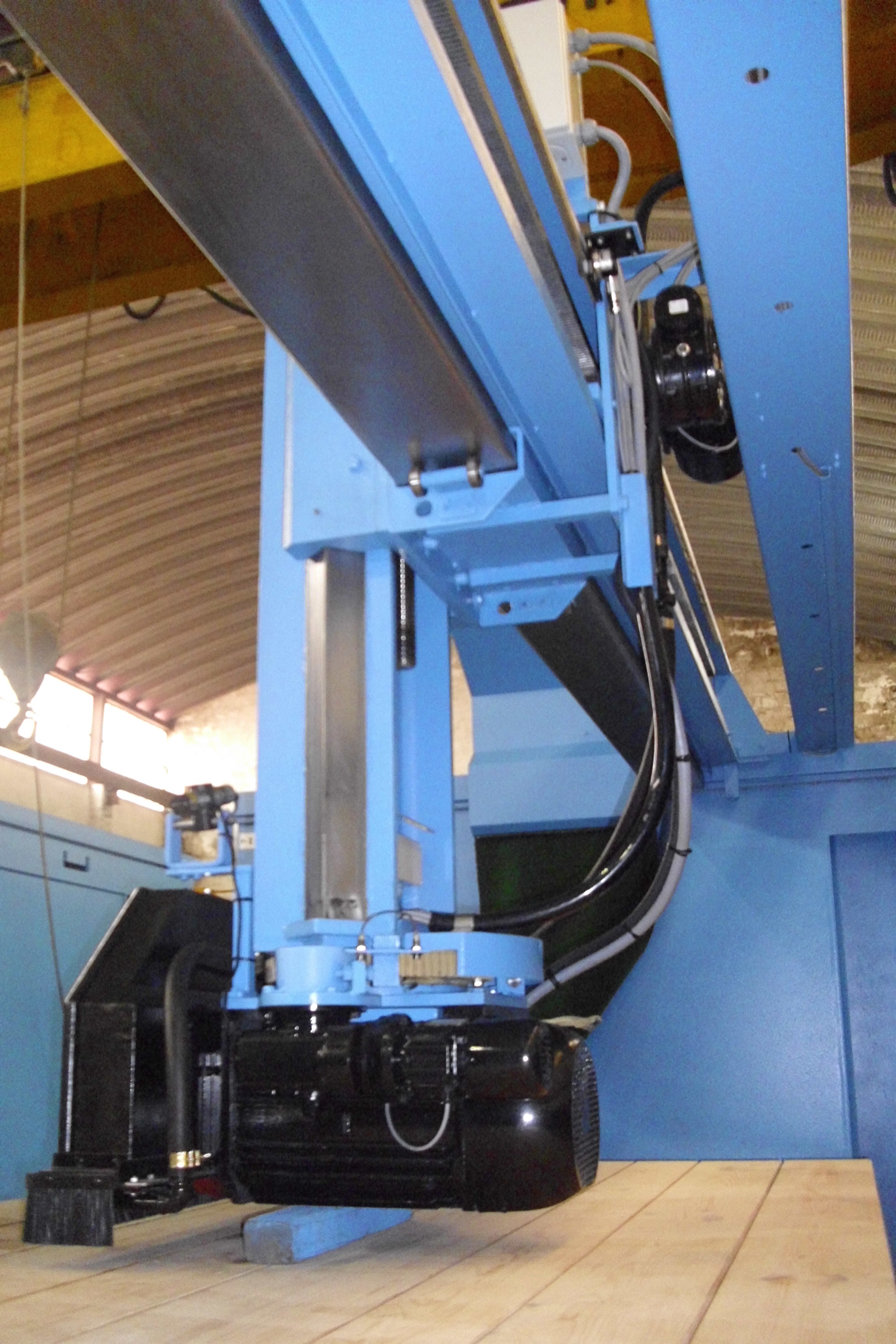

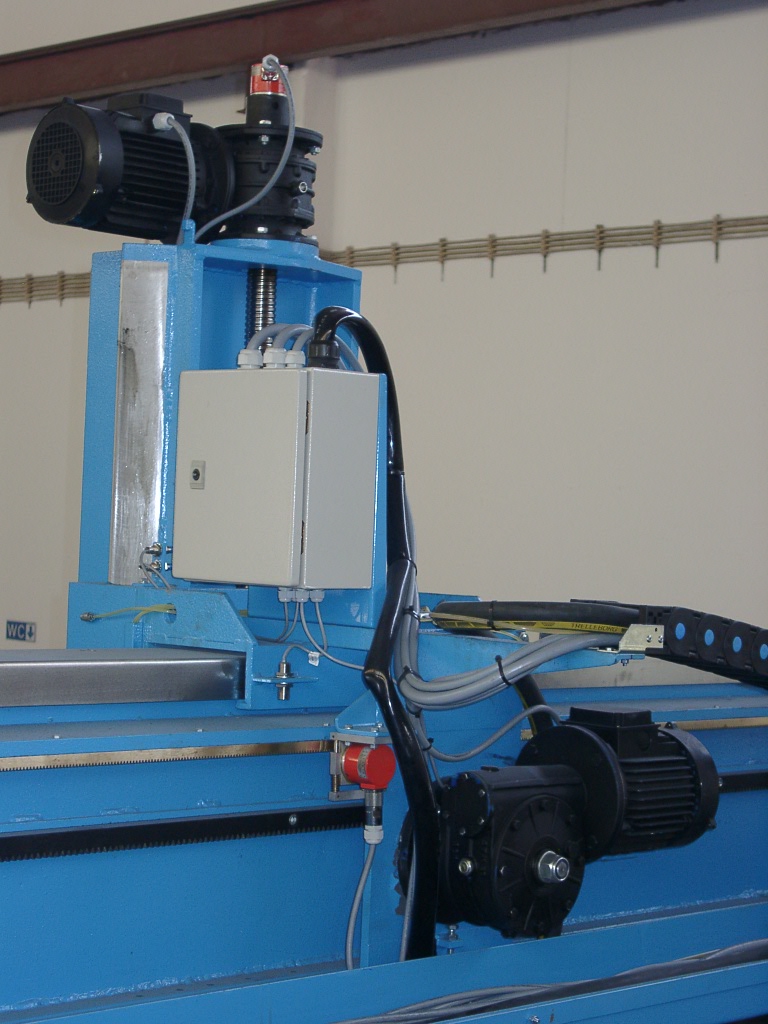

Can Assemble the Bridge Saw Over Metallic Structure

A good equipment support is primordial for a maximum yield on cutting process effort. We have two metal columns models, that can be mounted, depending of the bridge width, the ram height and the available power. Above structural value is suggested that the mounted be made on concrete. Since 1985 we have been assembling with 30 horsepower and 44 amperes effort. After 2002 we started to provide a 236 in / 6m cutting bridge for 55 ampere shear effort or consequent ram movement inversions.

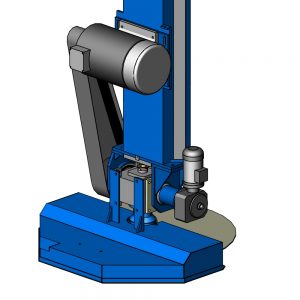

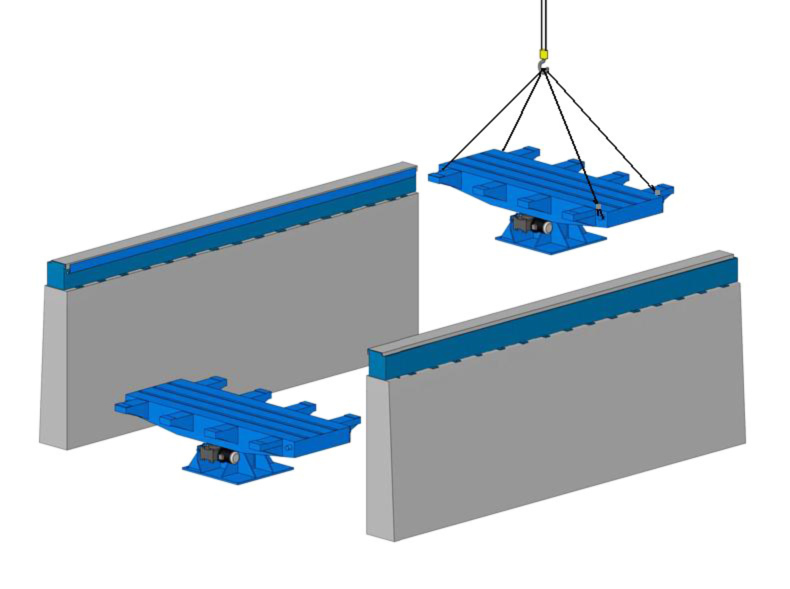

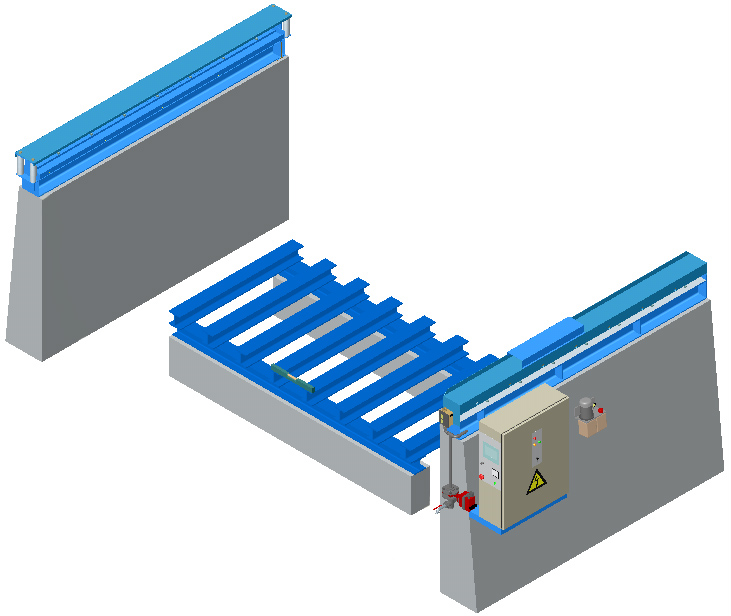

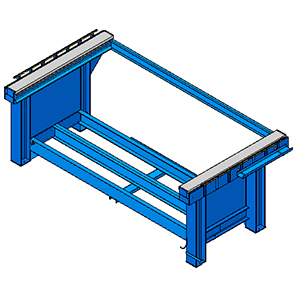

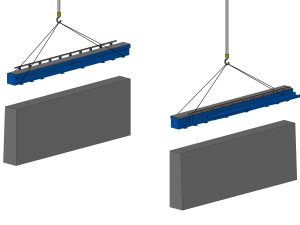

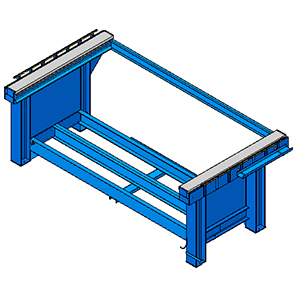

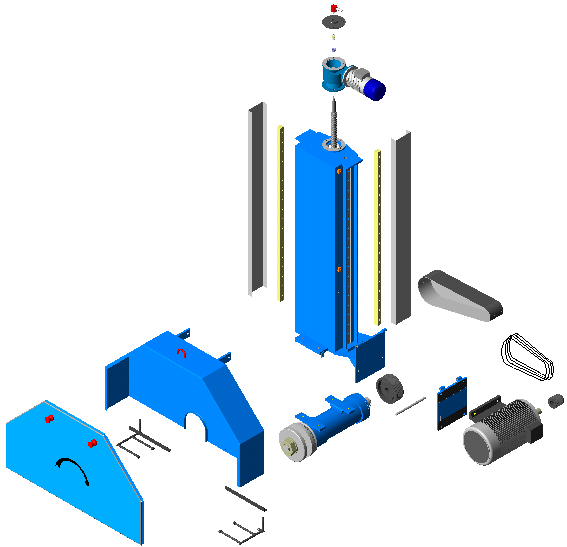

Monobloc Frame

Concept presented with an compact structure as a one-piece mono-block for easy installation and faster on-site equipment exchange, boasts thicker steel legs creates the monobloc, The main board separated from the machine to avoid vibrations and has easy access to programer screen. Maximize the cutting process with a precise and solid cut due to the use of the latest technology. It can be configured with one frame or multiple frames or only the continuation of lateral rails providing more bridge displacement for machines up to 43 inch ( in ) / 1,1 meters ( mt ) of the diameter and bridge length until 236 inch / 6 meters.

Metallic pillars

The metallic pillars are constructed as a single piece in order to increase the structural resistance and it are supported and fixed on a firm base, ensuring optimal performance. Regarding the surface treatment it is cleaned with steel shot, hot zinc plated and painted with three layers paint.

For operation with cutting operation, limited by maximum height and length.

You can mount accessories supports on the side, as material position markers or as a basis for laser focus. The position of the electric cabinet can be defined by the basic direction of water projection.

All the equipment works on the pillars. Outside, this support the remaining elements, as water valves, pressure controls, lubrication systems and cable carriers and water hoses. These pillars are suitable to use with double ram, because the effort movement follow the structure length. They are provided with a maximum length of 334,1/2 in / 8,5m and a total height of 98 inches / 2,5 meters.

Mixed Pillars

Can be suggested an only metallic pillar for situations of greater effort or as a way to assemble elements such, as workbenches.

Reinforced Pillars

These pillars are structurally larger on inside. The support base is wider and are suitable for use high ram, constant repositioning movements of the head, and when greater height is desired for placement of the cutting bridge.

All Hercules Serie can be mount on metallic pillars, being conditioned by height, width and power, but the maximum diameter and the placement of the control board don’t compromise it. Normally, the pillars are provided until 82,1/2 in / 2,1 m diameter.

The bridge to the ram displacement is positioned over the tops of the pillars, that are constructed in vertical. The cable carriers and water pipes are fixed directly, and the electric board can be aggregated, but to eliminate vibrations normally it is positioned separately, requiring longer power cables, also the command can be assemble on middle of machine providing an direct view to the working progress.

When the height is too high, the equipment performs constant repositioning movements or for great engine power it is mount a back lock. The data display screens, and the support box is mount ahead, for the command not to get lost.

The ram height is biggest than the pillars. It is necessary to check the availability for the total assembly, depending on the requirements. The base dimensions for each range are in the Foot Print menu.

Concrete Pillars

It is getting the maximum stability with displacement of the assembly rails for concrete pillars. Designed to be easy to construct, it requires accurate distances and alignments, and without this precision isn’t possible use the maximum power. All Hercules Serie can be mount on this format.

Two tables with open pillars on the side allows the operator to view the work on the outside. Two twin rams with 300 in / 7,6 m, or longer until using 787.1 / 2 in / 20 mt lines which is available depending on the range from approximately 730 in / 18.5 mt to 756 in / 19.2 mt. This length will be fully utilized to monetize the cutting process and reduce downtime.

Through these tested solutions we aim to maximize the available factory space for increased production. Can be delivered an equipment to works with maximum useful height, length or width. The equipment should be designed to eliminate turnaround times and get the maximum cutting power on the material to work, getting a maximum production. Normally, our deliveries are conditioned by the capacity of the diamond segment and the resonance of the cutting plate.

The most demanding ranges and use of rams are designed to also be placed on concrete pillars. It is conceivable dimensions of the range in order to mount on already installed pillars. Over-range dimensions can be designed to be mounted on columns already installed. Concrete or granite countertops can be applied where leveling is achieved by the equipment in surface grinding cycles. We make available concrete pre-built for an easy initial assembly.

The concrete construction must be solid, large upon request and the iron shafts must be out to weld the set screws.

On concrete pre-build

The upper surface must be correctly aligned and leave the gaps open to allow mounting and closing after equipment testing

Can Adopt Multiple Frames Structures to Increase Displacement

The multiple frames can be linked by top plates using bolts, thus mode can improve more displacement with the monoframe structure. Have an well utilization on provisory construction sites.

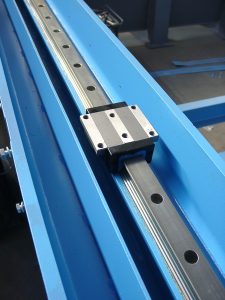

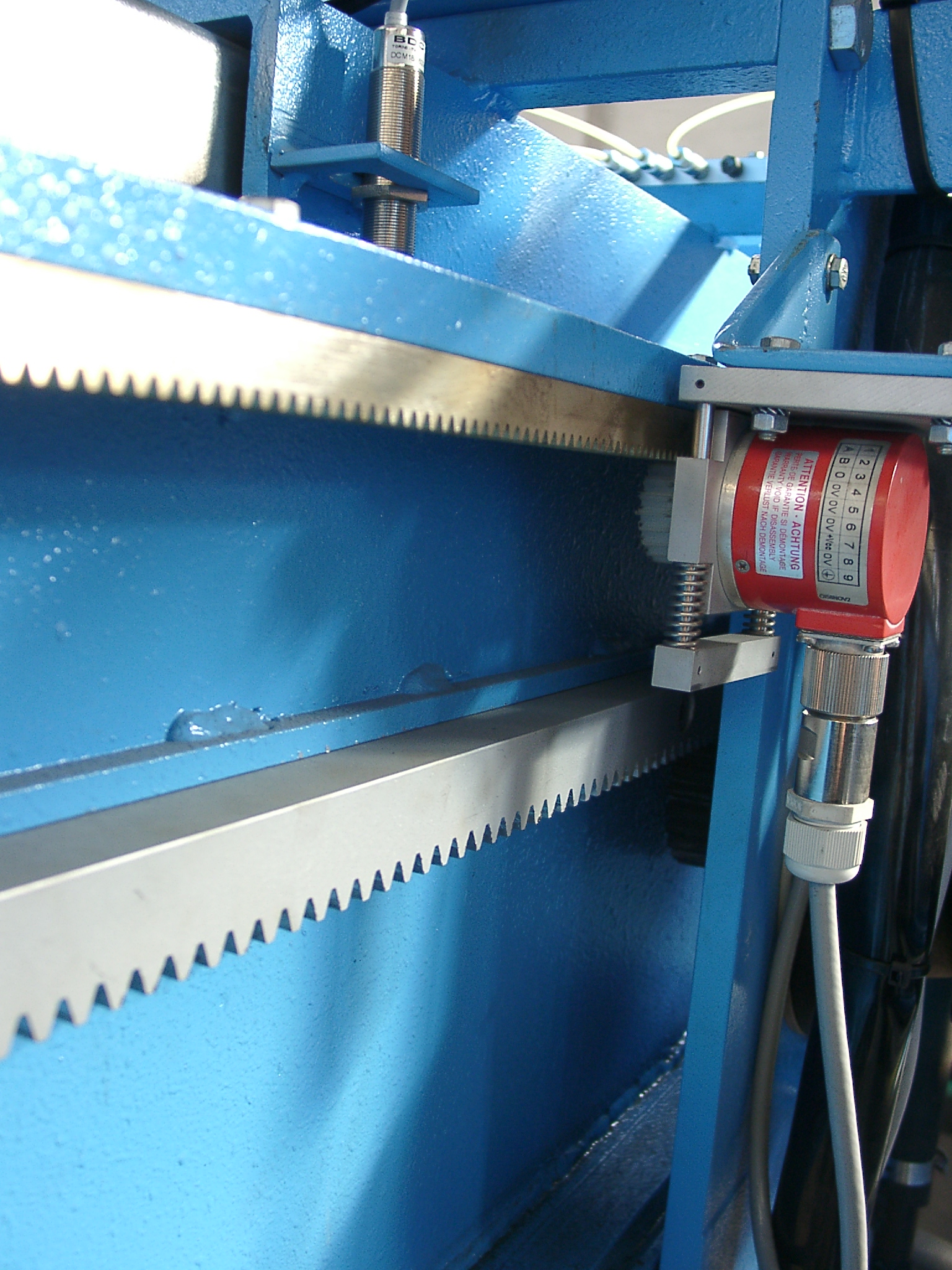

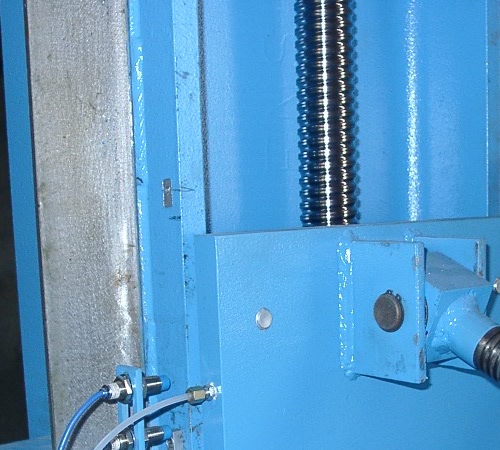

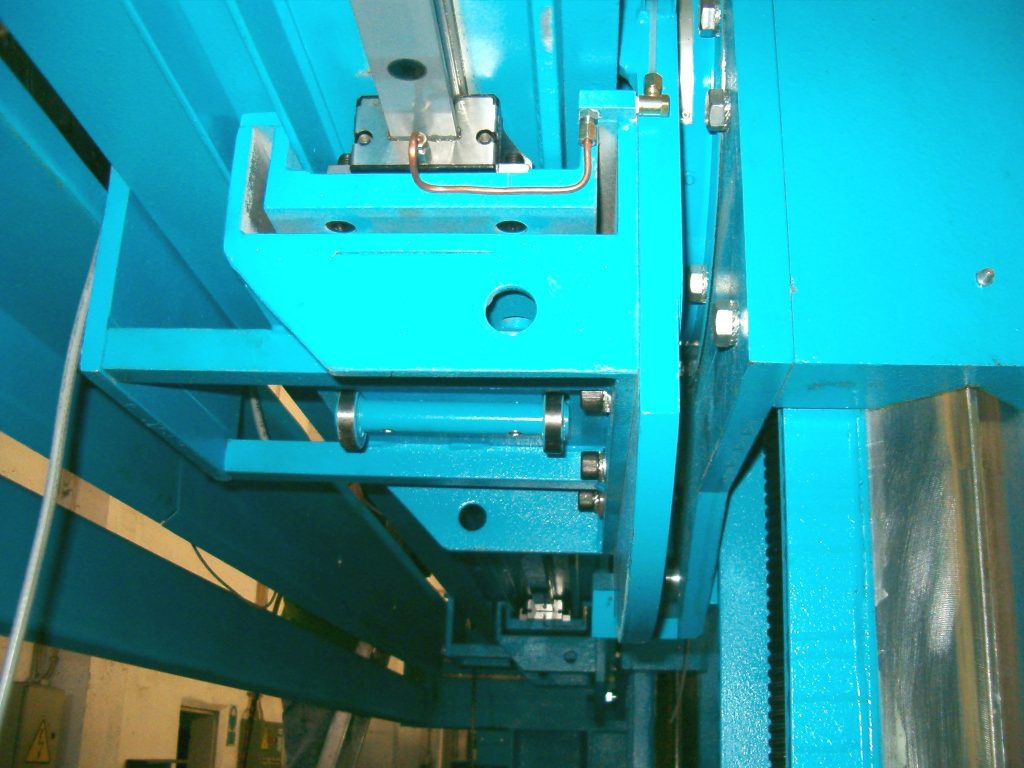

Side pillars are a component of extremely important equipment. An anti-resonance system was developed in these. As a way of eliminating micro vibrations caused by tools, they release a chatter that alters precision parameters as well as measuring the incidence of small marks on the material. On side of the electrical panel we put a constant coverage monitoring in linear bearing, which applies on a support surface. This is a large size to receive the load caused by cutting effort. The linear bearing can move in full oil bath, without twisting maintain a constant alignment of the bridge for displacing the cutting head.

The laterals rails can assemble over metallic structure, monobloc frame

In all Hercules Series the construction is constant. We decided to do more and use it for small needs, because our focus is the high thickness cutting, we developed it to top effort and weight.

In all gamma the cables run along the pillar to be in perfect order to work on the bridge.

Use edge extensions to allow back space work

It can be supplied with back extension, which can receive the bridge to work on solutions like lathe. Roller bench, palletizer and more in the Increase Potential and Working Bench’s Menu.

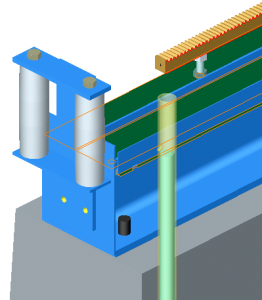

Machined surfaces on every alignment parts and support

Working on oversized displacement linear bearing guide with two bearings allows the perfection in all positions and increases the displacement velocity. There are two separate boxes, one can work with oil bath and the other removes the projected mud.

Assembled rack on both sides with adjustment

The weight of the rails is always the same regardless of bridge stress positioning, traction and alignment. With an oversized construction, we guarantee perfection on the side rails as well as the inner rails. All adjustable in positioning and fixed by iron bolts, the rails move from bottom to top of the gear, machining at once, ensuring perfect alignment of parts for a long time.

The bridge body works above the rails with weight distribution

The bridge is made of a single solid component and mounts directly to displacement carriages located on side supports and connected to precision rails, and an entire axle connects the double rails by the gear. We guarantee perfect parallelism in all bridge positions. On the side pillars there are several surfaces prepared to receive the rail fastening adjustment, independent of the motorization measuring system, linear bases to receive the precision bearings and also the contact surfaces to avoid high stress lifting.

Stainless iron guards assemble

Can mount guards on stainless iron or bellows. We mount the bellows on small displacements, and the stainless 1/8 in. / 3 mm. in all others dimensions. On the top we screwed it and the displacement carriage has a bearing support to allow perfect movement on long distances.

Both pictures show the both sides. The interior has separate boxes to avoid the mud, for oil bath work, the side box has different dimensions on each side, on the mud side there is a system for removing resonance and on the other side the linear bearing guide for providing constant parallelism.

The conception of displacement cars on the rails is removable on assemble

We started using linear displacement bearing guides in 1993. Displacement systems have been developed and refined to increase the power of the cutting saw. The production is and to keeping equipment and finish quality.

Experience and knowledge enable us to ensure that this mechanism is the best option for exploring the equipment in all configurations with cutting benefits.

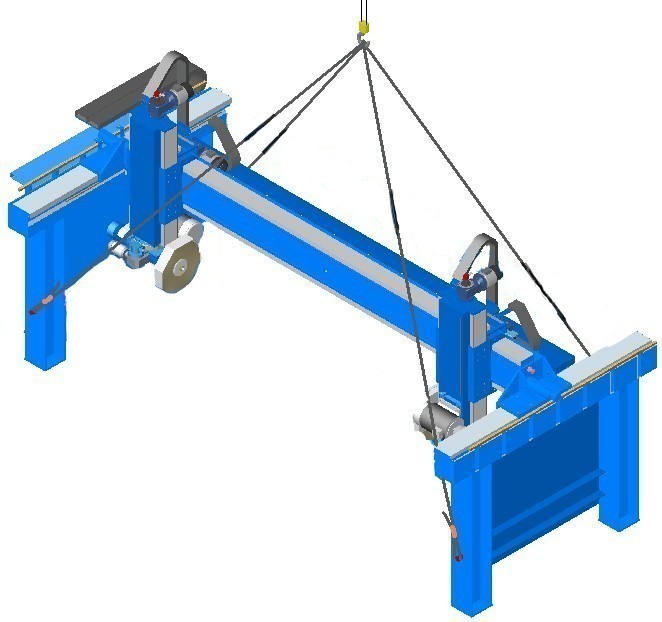

All equipments are total assembled on factory and subject into an exhausting test control

Small parameters are adjusted in the assembly process, parts are deposited in a transport box, plastics to cover the motors.

Assembled over concrete or metallic structure

The structure size of lateral displacement rails is always the same and can be mounted on the concrete with level screws and securing bolts. Additional elements are designed to be mounted on concrete as well but bolted to pillars.

Standard manufacture and procedures

Hercules Series pieces are designed in series to improve their quality as a product, part and component that will integrate the equipment and thus build reliably. If you think in profit and production 24/7 at full time, assemble by working process to ensure the well final product, and check every part after placing it on several components to send to final address.

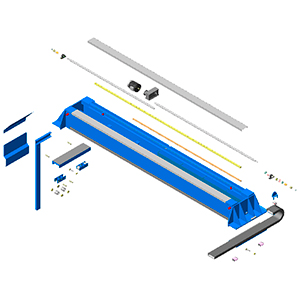

Several Sizes, Same Concept to Accommodate the Multiple Cutting Heads

The concept of the Hercules series is to share components and the concept across gammas. With the development of cutting heads since 1985, where we produced the first vertical ram with an adjustable V-system, we have been improving the displacement of cutting cars to this day. Using dual coupling methods, we provide the best level for customer work, with robustness and versatility ram for a fast-displacement car. We have several displacement, robustness and body sizes options (as shown in the initial image) to optimize work, mixed with the head change system, everything can be done and eliminated.

Direct power on cutting saw

This cutting power solution provides maximum saw power. Limited to diameters until 29,1/2in / 725mm, we assure the best optimization of cutting process. The head can be supplied with various options as rotation, fixed or adopting the multiple head. It can be used with confidence to adopt the concept 24/7. (Described on proper Cutting Head menu).

Cutting engine directly connected to the disc, so that all available speed and torque can be used without loss of power, thus improving the cutting power. For low speed cutting, we mounted an inverter with one or two reduction levels of pulleys to increase torque.

Several lengths providing the best work capacity

Intend an bigger cutting effort can use the rotation head with blocking system at 0 / 90º or also the 360º rotation table

It can be used on the mono-frame structure for easy installation and faster on-site equipment exchange (for machines up to 29.1/2 in. / 725mm. of diameter or more depending of working materials choose).

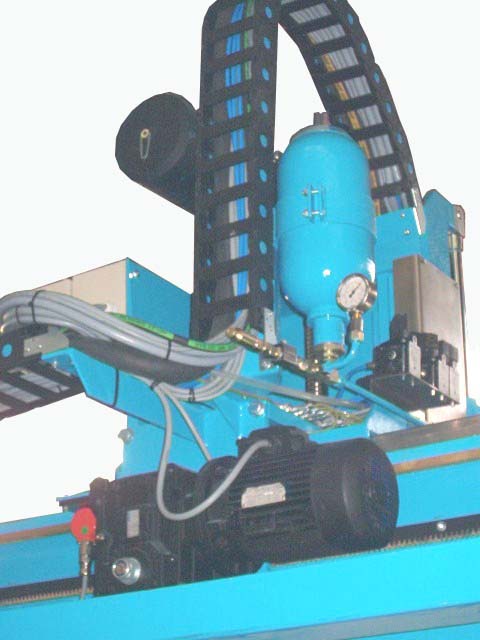

The displacement of RAM is constantly supported on bridge cutting car

Increasing the height in the occupied space can adopt more length, change the way of cutting, more cutting diameter, optimize multiple head in the work area. Vertical linear bearing displacement support is selected in case of positioning speed improvement, or compensator weight need to increase repositioning needs. The guides are protected with mud guards and allow oil lubrication under correct conditions.

Several displacements on vertical ram

Displacement System Ideal

16 in / 400 mm V one passage cutting with high power

27,1/2 in / 700 mm V or Linear multiple heads , inclination head

35,1/2 in / 900 mm V or Linear diameter range of motion , inclination head

Technical Features

RAM type System Ideal

Cutting with specific disc V high power transmission

Multiple head work V or Linear the start of multi-purpose

Multiple head with high amplitude Linear high velocities and travel

Robustness and best optimization

The bridge shift carriage provides a perfect accessory for the vertical work ram.

Ram is mounted completely independent of the displacement car to allow future upgrades to do the work better.

Ram is improved with the best components such as a hydraulic weight compensator and a ball screw. All contact surfaces are machined, and the interior has an industrial shape focused on work performance, not beauty.

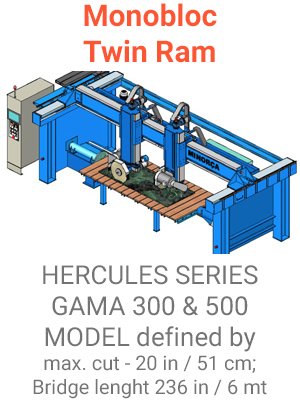

Twin RAM over Monobloc

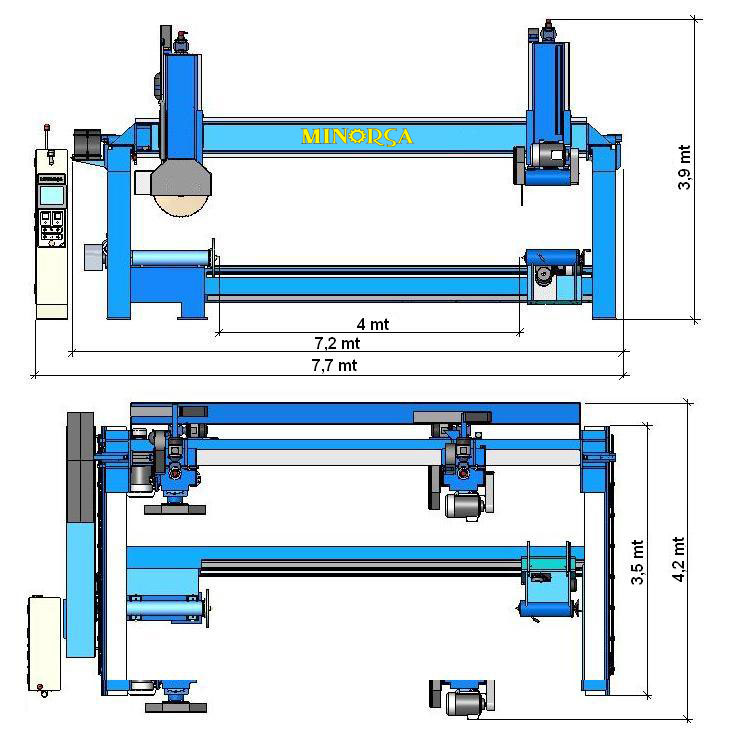

About

Its ability to turn a piece capacity with its own design programe, means it can do grooves, square pieces, etc.

Technical Features

✓ Diameter of the disc permissible – 600mm to 725mm (900mm)

✓ Maximum cutting hight – 235mm (Falange 250mm)

✓ Vertical displacement minimum – Z= 470mm (for more optional)

✓ Cutting capacity – X= 4,000mm (for more optional)

✓ Power of main motor – 15 kw (20hp) / 30 Amp. ; 22kw (30Hp)

✓ Approximate minimum weight – 7,000Kg

✓ Maximum height required for operations – 3,9 meters

✓ Cutting displacement velocity’s – 20 mt/min.

✓ Minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

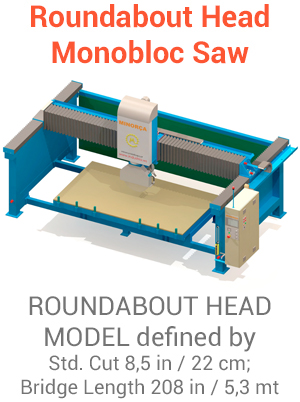

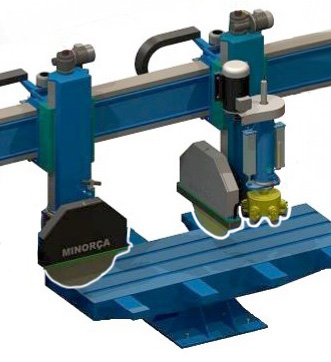

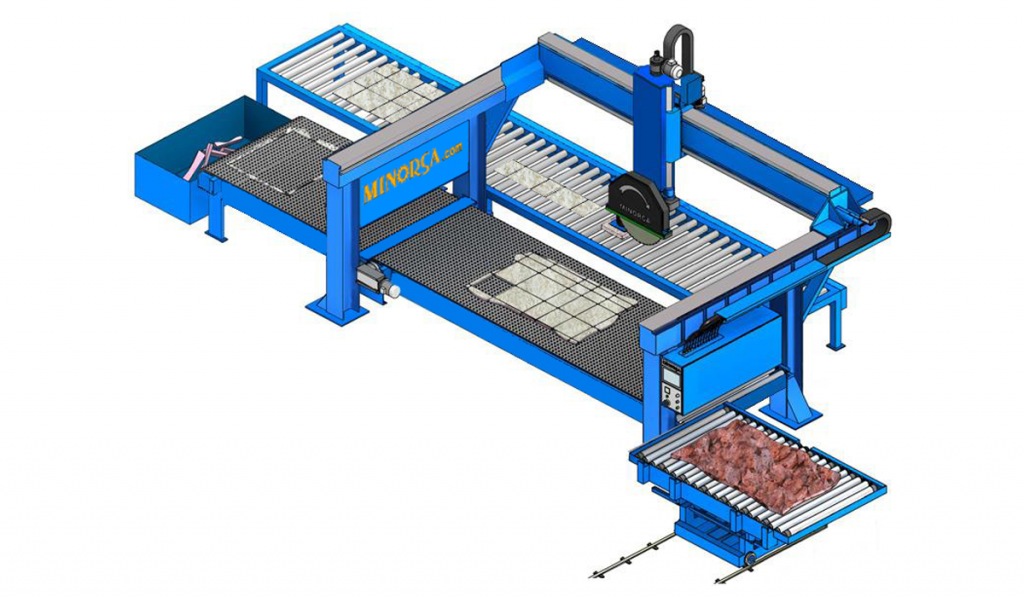

Roundabout Head Monobloc Saw

About

Is the “missing link” between a classic CNC work center and a sawing machine.

Hi-Tech is able to carry out processes typical of both types of product:

Cut in all directions around curves and 45° in fully automatic mode.

Milling, Grinding, Polishing even the kitchen tops, Engraving / Gravestone, Writing and creating bas-reliefs for the tomb stones / Headstone industry and much, much more thanks to its electrospindle for ISO 40 cones or the profit center head saw on multi heads change abilities.

Bridge length between support walls

240 inch / 6,10 mt GAMMA 500 assemble diameter 28,1/2 in / 72,5 cm only vertical

208,1/2 inch / 5,3 mt GAMMA 300 assemble 23,1/2 in / 60 cm Vertical RAM on multi-work heads

230 inch / 5,84 mt (special size into 20 feet container)

There are various types and lengths of displacement RAMs to receive the multiple heads. It has a digital programmer that allows you to view various menus from the introduction of the cut dimensions to the appropriate drawing of the profile.

It provides an industrial console to enter the various cutting dimensions and allows controlling the cutting speed by checking the saw’s tension. Also allows the return of the cut at maximum speed.

This presentation is specific to the bridge saw over tilt bench and an conjugated use of center head saw, know as roundabout head monobloc saw

Ideal for bridge crane loading and slab work up to 2 in / 5cm, it is coated with marine wood or recycled plastic sleepers, with hydraulic system, and can support weight without twisting. It is also possible to adopt the pneumatic inclination only to receive the slabs. It has an integral frame to allow the exchange for another workbench to work in the same space. The top base dimension starts on 118 in / 3mt and can be made until 157,1/2 in / 4mt or more with the hydraulic tilt if necessary.

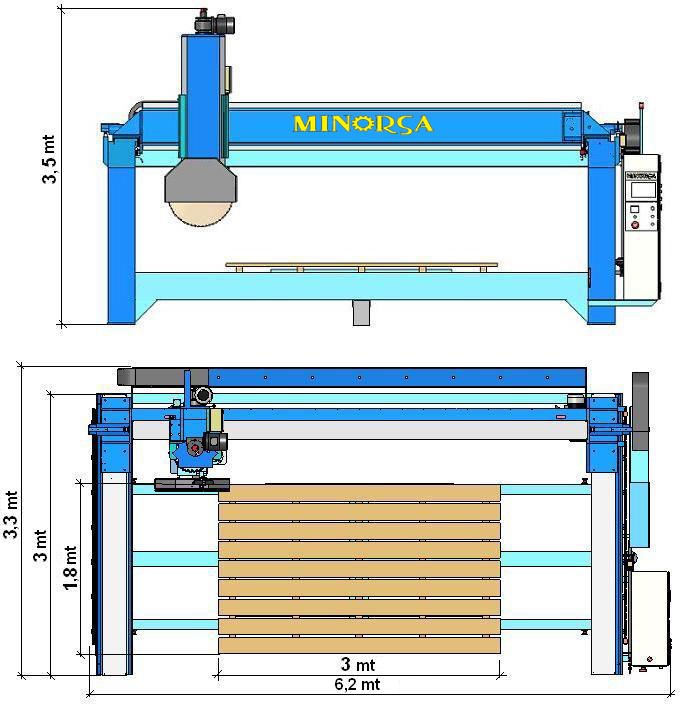

Technical Features

✓ Diameter of the disc permissible – 450 mm to 725 mm (900 mm)

✓ Maximum cutting height – 220 mm (Falange 280 mm)

✓ Vertical displacement minimum – Z= 400mm (for more optional)

✓ Cutting capacity – X= 3,500mm x Y= 2,000mm (for more optional)

✓ Power of main motor – 15kw (20hp) / 30Amp. ( 22Kw (30Hp)

✓ Approximate minimum weight – 6,200Kg

✓ Maximum height required for operation – 3,3 meters

✓ Cutting displacement velocity’s – 20 or 37 mt/min.

✓ Minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

Central cutting saw for an easy positioning by cnc system

Technical Features

✓ Diameter of the disc permissible – 450 mm to 725 mm (900 mm)

✓ Maximum cutting height – 220 mm (Falange 280 mm)

✓ Power of main motor – 15kw (20hp) / 30Amp. ( 22Kw (30Hp)

✓ Minimum peripheral speed for cutting – 28 or 35mt/sec (can set up with inverter)

Tilt table for an easy load of slabs

Ideal for bridge crane loading and slab work up to 5cm, it is coated with marine wood, with hydraulic system, and can support weight without twisting. It is also possible to adopt the pneumatic inclination only to receive the slabs. It has an integral frame to allow the exchange for another workbench to work in the same space. The top base dimension starts on 118in / 3m and can be made until 157,1/2in / 4m or more with the hydraulic tilt if necessary.

The Mono Frames Ready to Receive All Gamma 300 and Some Bigger on 500

Bridge length between lateral rails on frame Available cutting capacity

Interchangeable working heads provide maximum blade capacity (43 in / 1,1 mt)

236 inch / 6 meters (with the gamma 500 bridge assemble)

208.1/2 inch / 5,3 meters 128 inch / 3,25 meters on sandstone

( in the cut of granite by increment steps will be more )

16,3/4 in / 42 cm disc 43 in / 1,1 mt can work into the flange round

Will accommodate on frame the GAMMA 500 bridge this disc’s diameter without head change

For more length or admissible diameter on interchangeable cutting heads must see GAMMA 500 or 800

Bridge manufactured in 2 gammas (sizes) 300 and 500 to use on monobloc concept

Since 1993 we use this displacement system and in 2012 the oil bath capacity.

Serial production of well tested components used for several gamas

Surface treatment on metal components. Steel grit blasting grease removal, and thermally applied zinc coating. This protection is reinforced with an anti-deterioration / aging finish by means of an undercoat, a graphite rubber component layer and high gloss paint top. Hence, we guarantee maximum anti-corrosion protection against its common operating environments.

ALL EQUIPMENT STRUCTURE is designed in forged steel using MIG welding

Independent counting system on appropriate measuring rack. It is an equipment with protection guard and stainless-steel bellows, and that support bearings to keep maximum saw pressure on stone.

Fast and Easy

100% monoframe

Level, make the wire connection, water on, take final tests and work specific training, and it’s ready to work 24/7.

Testing on factory and final assemble on work place

All equipment is subject to a verification list at the end of production and in place with the assembly process.

Technical drawings are offered for better capacity utilization

Since deployment settings, work capacity and appropriate skills, we have an cabinet to solve your needs, from the factory space organization, the layout of the work, check in on site, we can provide the solutions to do a better job, environmental solutions, and profitable working.

Working and assemble manuals

We provide the work and assembly manual with simple design for everyone to understand.

Common Parts

The Hercules series adopts the principle of using common parts by changing their sizes by gammas.

Standard Parts In:

Working tables

The intention is to indicate that the parts and components produced starting in a project were subjected to intensive tests over 50 thousand hours. In the Hercules series they are used according to a manufacturing plan, from individual design of the pieces to their join assembly, with an accessory or component that will be combined with other to get a reliable and cost-effective equipment, easy to operate and maintain, and usable to its full capacity either in production or in its profit.

Cutting heads

All the components are designed to be interchangeable between the Hercules Series. Is this the concept that we intend to present: developed, tested, interchangeable, capable of receiving various upgrades, potential for expansion either in power, and that allowing the accessory exchange.

Measure system with independent counting

Based on the concept of making full use of head swapping equipment for multitasking, on the same bridge can be mounted more than one ram model. It is possible with two side supports, with one of two powertrain systems, with two transmission systems or with one of two control systems, but always with the highest quality products.

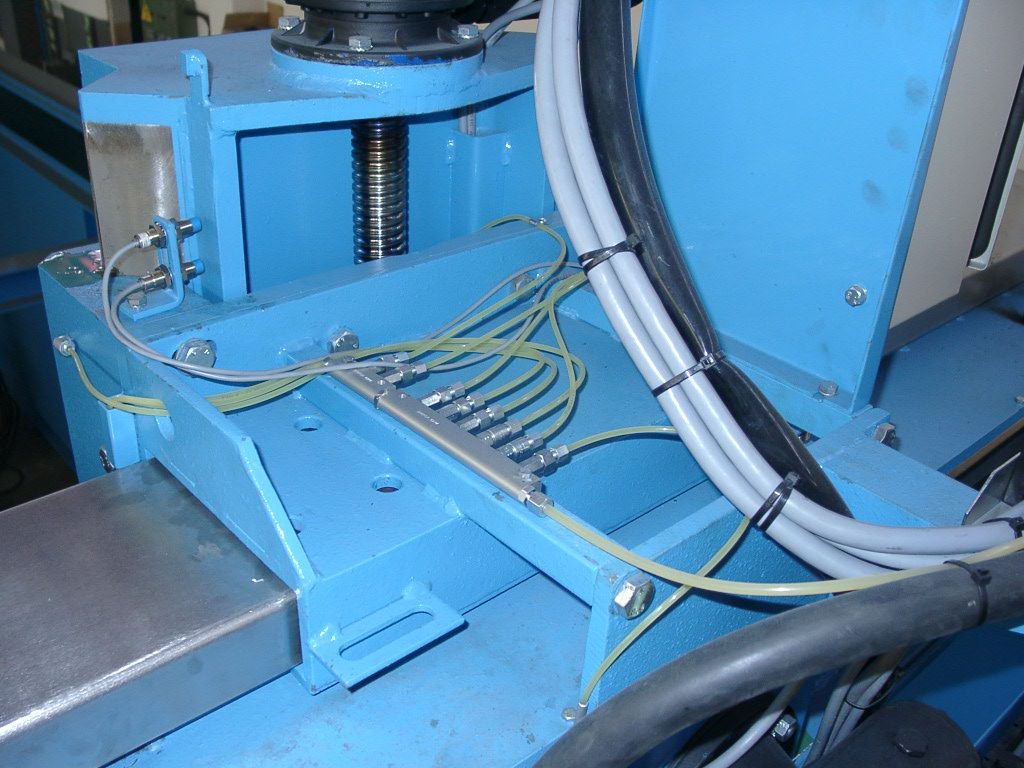

Independent gear counting system, which increases reading accuracy without the use of transmission elements, allowing positioning of the displacement elements/axes with a maximum error of 2 tenths of a millimeter.

Junction box for shaft cables.

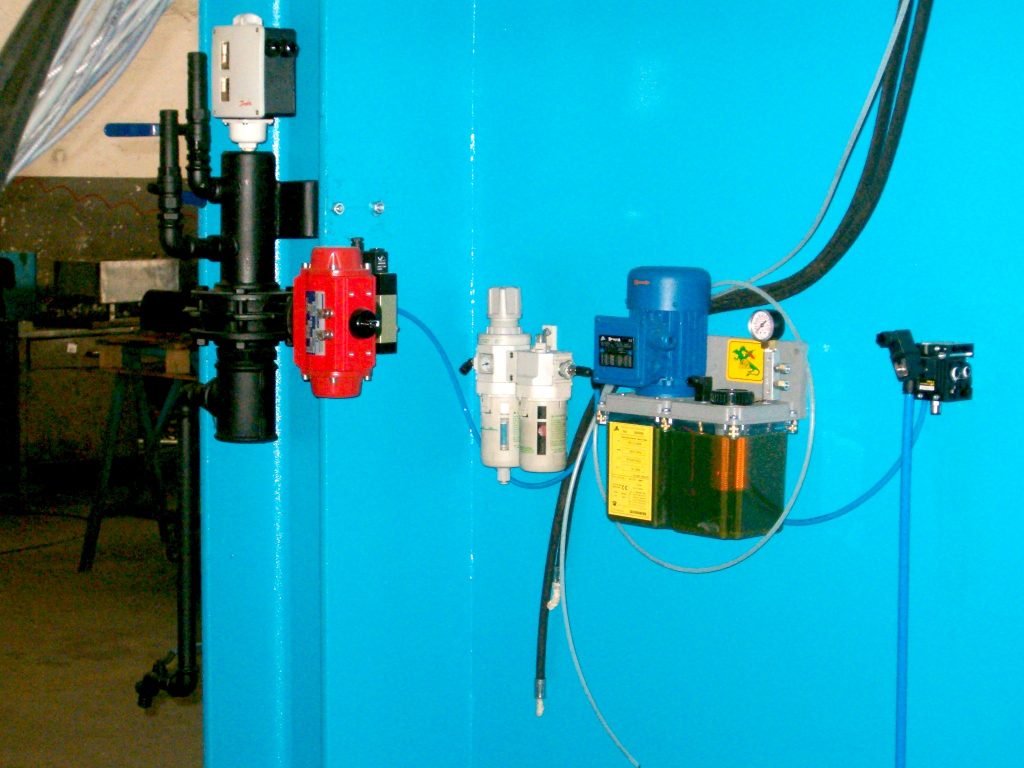

Automatic lubrication on all displacement points: water on/off automatic valve

The auxiliary components are also selected for their good operation and easy maintenance, and the security systems are assembled for easy identification and protection from events.

Power failure recovery (position and status memory) to continue working automatically, saving time and materials to be cut;

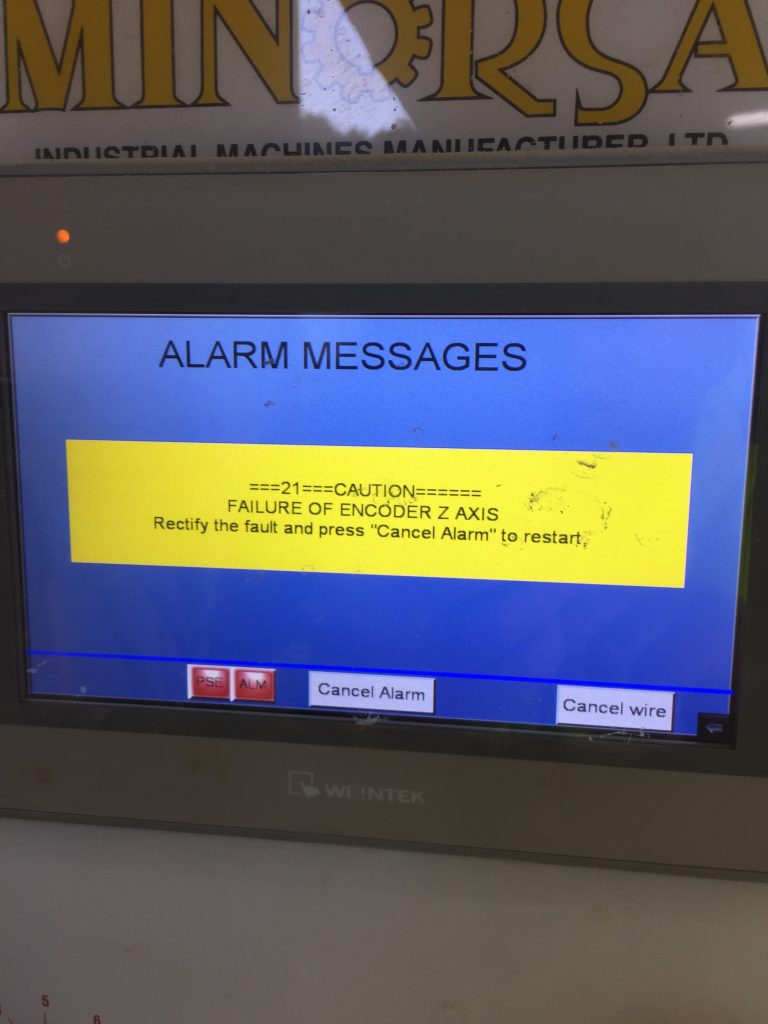

Automatic cut-off stop protection, if material gets stuck, slow down or at the end of the program;

Automatic axle stop/protection in case of mechanical anomalies during operation;

Displacement stops cease working to avoid programming or operation errors;

The equipment stops when opening the electrical panel;

Low voltage manual control switch to protect operator;

Electric protection by using magneto thermal switches (without fuses);

Regulated power supply, protecting low voltage circuits against power surges;

The equipment stops after encoder pulse count failure or contactor obstruction;

Horizontal displacements in oil bath capacity.

Automatic lubrication system with times, which allows keep the equipment lubricated at all its constant movement points, without the need operator interventions with oil pressure switch in case of pressure loss in the circuit.

The displacements can be fully embedded in oil bath, eliminating supervision and increasing time between periodic maintenance. Thus, allow increasing its lifetime.

Laser with continuous focus

Accessories with laser focus, allows the use of laser for better alignment of the initial positioning on the pieces to be cut. One of its features is the individual variable speed transmission, which allows for more precise adjustment of speed and position. This also has water shut-off valves fitted as standard unless otherwise requested.

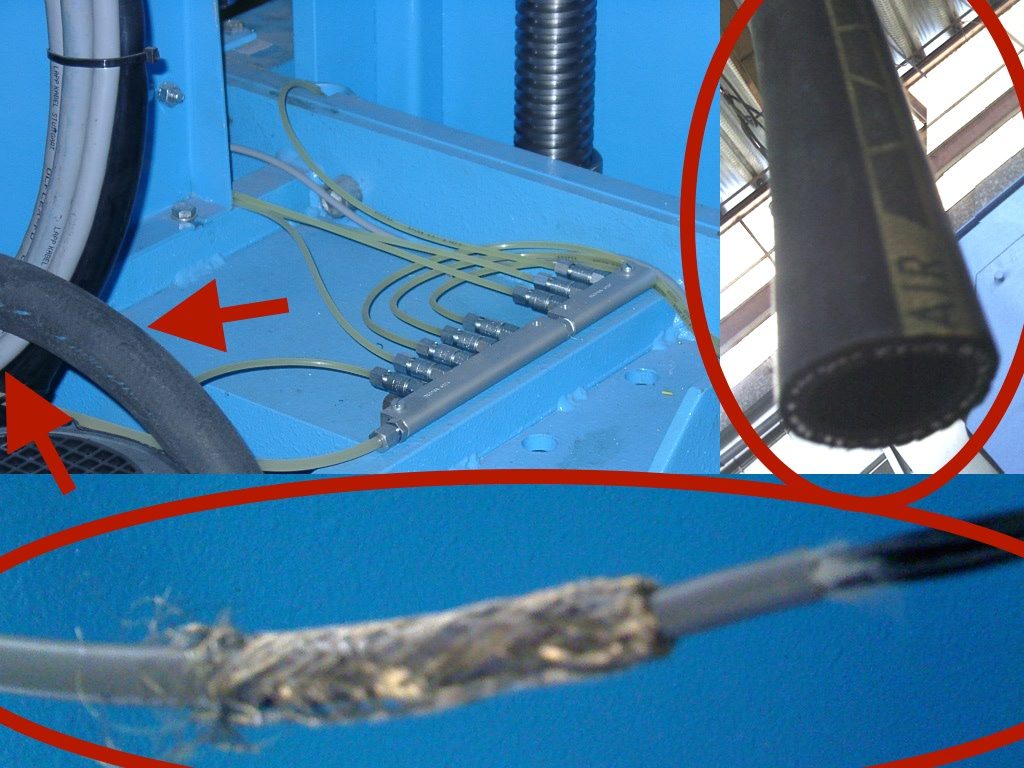

Water pressure system control/protection on cables by cover mesh/pressure water pipes

Special electric cables with mesh sheathed, moved through the cable supporting rails. Measure Encoder component with braided wire mesh cables (counting system) to protect against power surges. The base installation also has inner lined water cables consisting of a mesh reinforced rubber hose inside. Shields and rails for collecting the oil coming from lubrication of material used for cutting. Water pressure switch to control cooling and washing of the saw. (Placed on top of pillar for greater accuracy).

Electric board disconnected of equipment

A pit dimensioned with spaced components and embedded screen. The plate is separated from the machine to avoid vibrations and has easy access, because it will be installed close to the floor. This electrical panel is built in our facilities in compliance with all CE regulations.

Electrical panel ventilation system with temperature control. Software under development to facilitate data entry and reading, based on operator feedback and questions. Mains fault detection system.

Standard components of well reputed brands

Using reputable brand components and applying operating concepts ensures full operation in the future.

Multiple benefits and aid capabilities:

Managing several pieces of equipment from a main computer in the office through ethernet (sending production orders);

Ability to receive and operate complex draws or cutting cycles programs;

Production / cost control through a total hour counter or by works, and a total area counter, by works or saw;

GSM or WEB text messaging system that lets you know that the job is done or if there are any errors in the cutting phase;

Signal emission to check the condition of equipment at a distance.

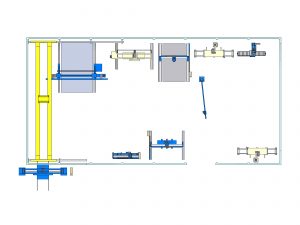

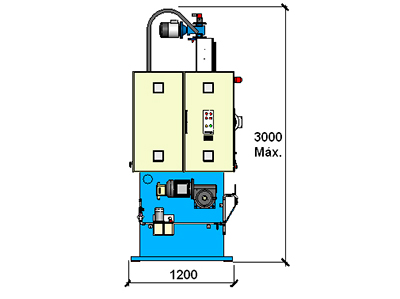

Foot Print

Equipment Read to Work Over Integral Chassis

The Standard Production Allows Increase Several Components in All Gammas

Radio control gives the operator more freedom of movement.

The flange is made to ensure that the pulleys system doesn’t reach the material.

The main screw is stainless steel.

An water projection fork in zinc treated iron is made to be removable

Allowing an easy change of the disc

Surface treatment is always done with a hot zinc projection base.

Metal side pillars are made in one piece.

An extension can be mounted to get close to the bench and provide smaller diameter discs.

This makes the equipment in the assembly taller to support larger diameters.

Water shields upon displacement of the rails may be provided to prevent the projection to the other side.

A support can be made to position the laser line above the cutting disc.

Centralized lubrication provided on plastic pipes with central connection elements.

Mesh reinforced rubber water hose, steel wire braided cables.

Water pressure switch to control cooling; Oil pressure switch in lubrication system, and air filters.

Junction box for axis cables and quick water connection.

Hydraulic compensators to provide an fast vertical displacement and also compensate for large saw diameters.

Flexible cables moved by the cable support rails.

The displacement carriage makes the connection between the bridge and the ram.It is possible that the proper displacement carriage tilts the ram on the side.

The Hercules Series is designed to have the highest cutting capacity overdue.

In the front tilt, the whole ram makes the movement by an axle connected to the displacement carriage.

Flag crane for working with suction cups or tweezers.

You can set the time on arm, capacity, electric or manual movement.

Big dimension Linear displacement bearing guides are assembled to increase fast and steady.

We can supply concrete pillars pre-build.

Industrial panel to allow work in industrial environment.

Pine wood bench to work with forklift or allow the small diameters work.

Size: 5,1/2in / 14cm high and 118in / 3m by 70,3/4in / 1,8m

Special order accessories, system in U shape to receive multi small stones.

Metallic frame with pine wood over to work by forklift and crane.

Copy system with electronic device to use on iron or wood mold.

Linear tool change for working with 50 or 40 iso heads.

The cover is automatic to protect from water projection.

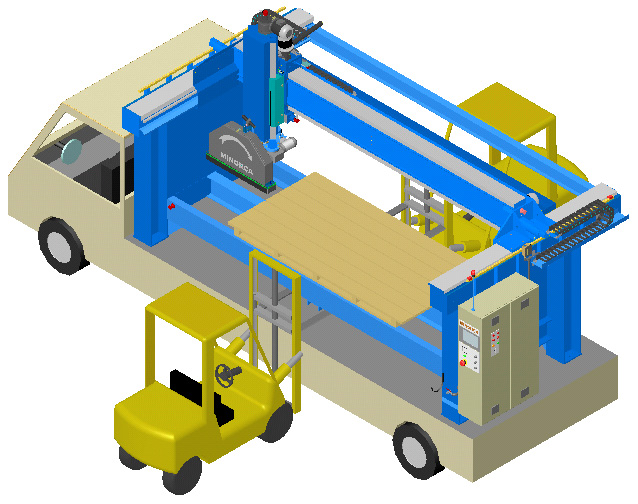

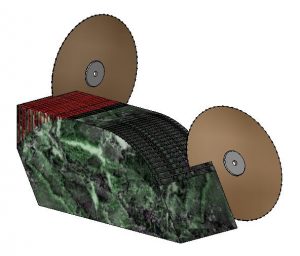

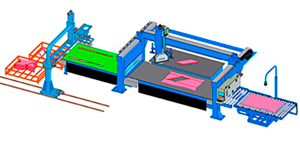

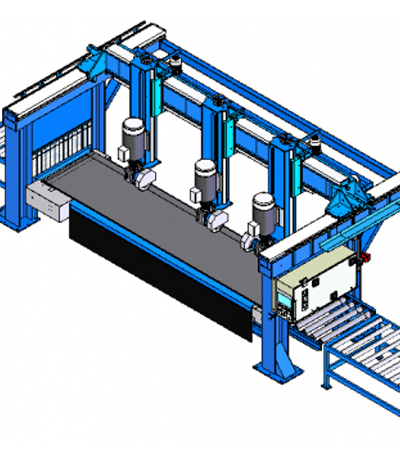

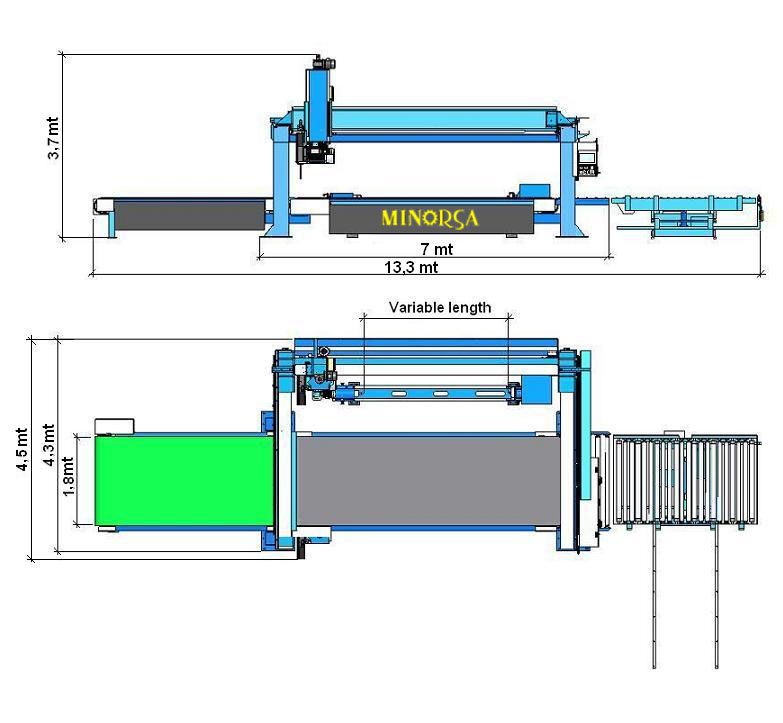

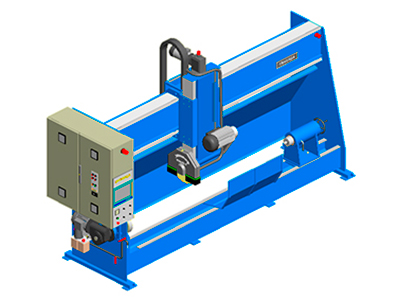

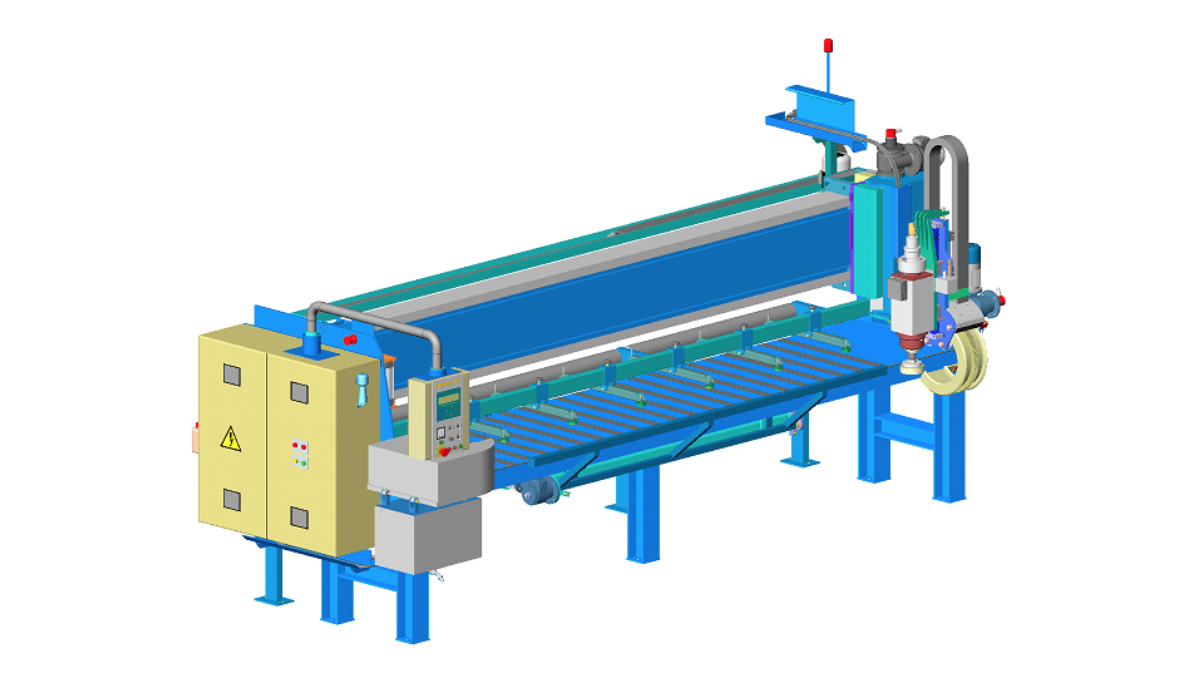

Hi-Tech Saw on Belt Conveyor

About

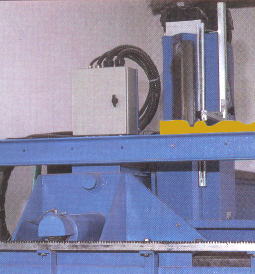

Currently, matching the Hercules Series in its Gamma 300 & 500, presents a concept of saw working over conveyor bench, making it the most profitable and precise cutting equipment. Rotary head improves the fast production, over several chooses on Multi-Purpose Heads.

It allows the use of a compact structure, quickly repositioned.

Operate the hi-thickness and hard material’s, quick movements, advanced software to maximize cutting processes. In order to increase the power of factory layout.

This equipment has several capacities in this concept, from linear cutting to circular cutting, can mount the twin heads on the conveyor, that can be assembled with several options, turning, automatic loads. Been perfect to adjust on processing cutting lines.

Technical Features

✓ Diameter Of The Disc Permissible – 28,1/2 inch ( in ) / 72,5 cm

(vertical only – 51 in / 1,3mt)

✓ Diameter Using The Inclination Systems – 43 in / 1,1 mt

✓ Maximum cutting height – 16,1/2 inch / 42 cm or 19,11/16 in / 50 cm

✓ Vertical Displacement Regular – Z = until 18,5 in / 47 cm or:

27,1/2 in / 70 cm ; 43,1/2 in / 1,1 mt

✓ Cutting capacity Available Regular – Long = 2,1 mt ; Large = 3,7 mt

✓ Power Admitted on Cutting Motor – 15 kw / 20 Hp ; 22 Kw / 30 Hp

on special assemble & config. 30 Kw / 40 Hp

✓ Height required for operation – start on 145,1/2 in / 3,7 mt

✓ Inside distance between lateral rails – from 157,1/2 in / 4 mt

(regular: 208,1/2 inch / 5,3 meters)

to 236 inch / 6 meters ( using gamma 500 )

230 inch / 5,84 mt (special size into 20 feet container)

✓ Cutting displacement velocity’s – 65,1/2 foot / 20 mt by minute

or 121,1/2 foot / 37 mt by minute

✓ Admitted peripheral speed of the cutting – 28 to 50 mt/sec

(one will select with max. power on +/- 30%)

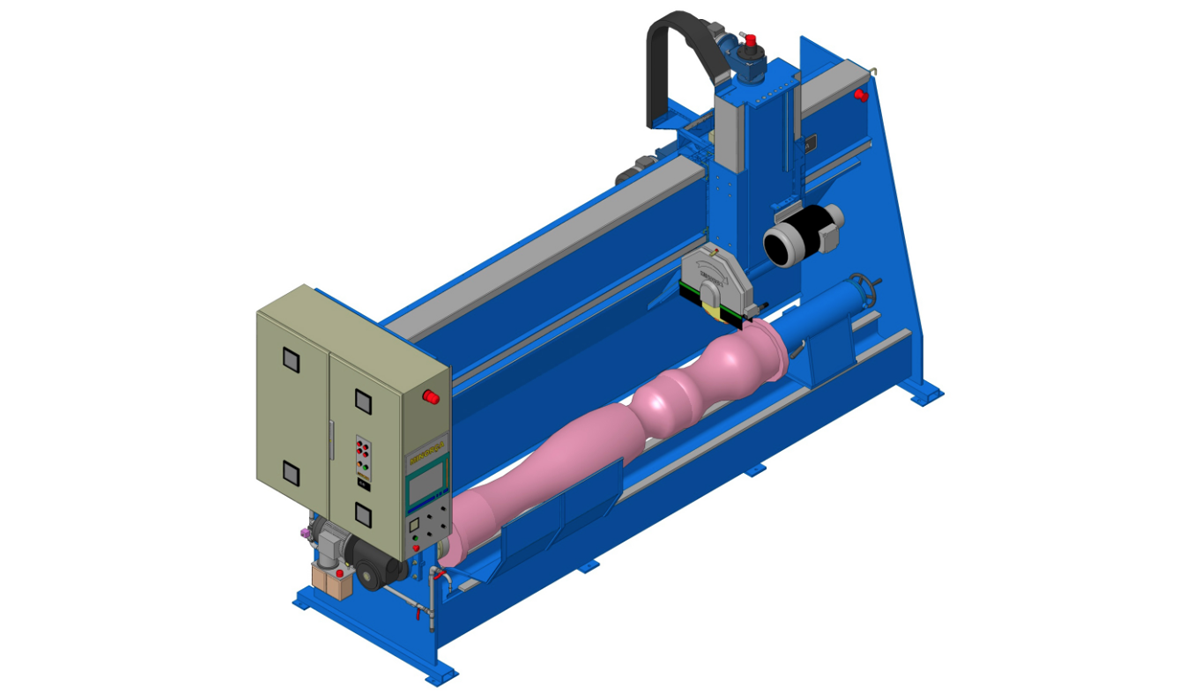

✓ Regular combi works – Rotating Axis on SPHERICAL LATHE Body

Produce rounds, squares and other shapes. The regular

dimensions are 118 in / 3 mt long with ability to

work 19,1/2 in / 50 cm. From a square shape, works

with one or two cutting heads.

EDGE POLISHER High Thickness shapes

Execute top face polishing and a max. thickness

height 4,3/4in / 12cm. Designed for thick polishing,

provide over heads change system.

ROLLER Bench to Stripes

Width starts on 31,1/2 in / 80cm and the standard

length is 118 in / 3mt plus on main body plus the

exit rollers until pallets, 236in / 6mt

Palletizer ROBOT , Tilt Bench , MULTI-Heads Exchange

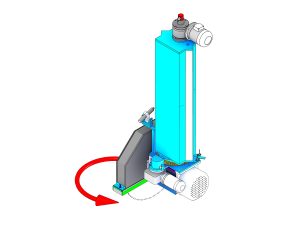

Spheral Lathe on Monobloc

About

Backlit interactive display which allows programming without need to stop the equipment, memory recover option, molds storage, etc.

Forged steel, with zinc plating and graphite paint surface treatment.

Monobloc structure, for easy transport and set-up.

Developed for fully automatic operation, which is programmed on the equipment itself by drawing straight line and arc segments. It also allows controlling the cut and rectifying speeds, leaving the piece totally clean and ready to be polished.

The displacement of the axles is done with electrical engines through linear guides placed on rectified beds. It’s lubrication is fully automatic.

Technical Features

✓ Diameter of disc admitted – 350mm to 450mm (p/+ optional)

✓ Maximum cutting height – 155mm (Falange support 140mm)

✓ Turning capacity – 3mt / 0,5mtØ beginning with the 710mm

✓ Cutting motor power – 7,5 kw (10hp)

✓ Approximate minimum weight – 3730Kg

✓ Maximum height required – 3,3mt

✓ Inside distance between pillars (p/+ optional) – 4mt

✓ Maximum speed head displacement – 4 mt/min

✓ Minimum peripheral speed for cutting – 26 or 47 mt/sec

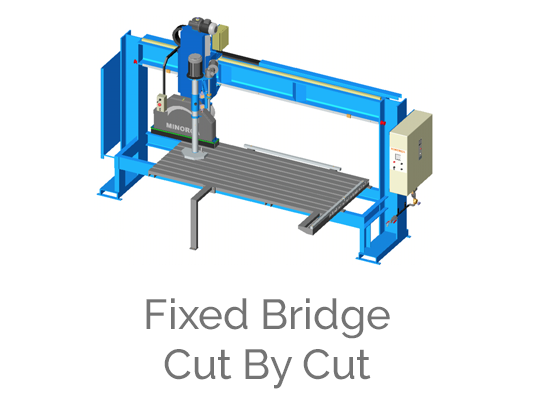

Fixed Bridge Cut By Cut

About

The FIX SERIES are compound by several components , that ones can be mixed and create easy machines to increase the intermediate tasks , using the same beam with linear milling box to assemble an reinforced steel and tempered square shaft will assemble the displacement car , can be possitioned on horizontal or even on vertical or in other possition as intend , simple solutions mixed together will provide high results over production , that can improve the cutting from piece to piece or mixed in an production line.

Defined as monoframe, can aggregate different bench types.

Technical Features

MIX THE COMPONENTS TO CREATE EASY USE EQUIPS OVER FIX SERIES

POWER COMPONENT

✓ Main motor admissible (max) – 15 Kw / 20 Hp / 30Amp. ; 22 Kw / 30 Hp

✓ Diameter of the disc permissible – 45 cm to 39,1/2 in / 1 mt

✓ Maximum cutting height – 14,3/4 in / 37,5 cm ( Falange 250 mm )

✓ minimum peripheral speed for cutting – 1,100 in / 28 or 35 mt/sec

(can set up with inverter)

VERTICAL TRAVEL RAM COMPONENT

✓ Vertical displacement (max) – Z= 18,1/2 in / 47 cm ( Max. 24,1/2 in / 62 cm )

✓ Cutting displacement velocity’s – 639 in / 16 mt/min.

BEAM COMPONENT (WITH MACHINING if necessary)

✓ Cutting capacity – 137,1/2 in / 3,5 mt on 23,1/2 in / 60 cm diameter

(Can be more, depending of diameters)

✓ Approximate minimum weight – 4,000 lbs / 1,800 Kg to 5,400 kg

✓ Maximum height required for operation – 102 in / 2,6 mt x 216,1/2 in / 5,5 mt

✓ Maximum speed on displacement travel – 315 in / 8 mt

✓ Belt are defined until the maximum of 2 meters

✓ Cutting capacity – = as the belt width

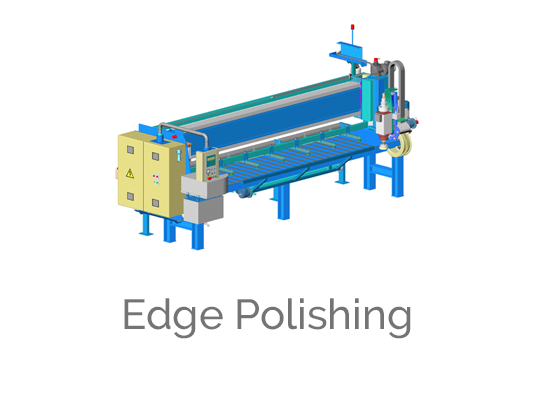

Edge Polishing

About

The polishing of the tops is done automatically, and it enables to carry out several forms and programming several cycles.

The working table is surface machined, providing an well alignment of material to work with the tool.

The edge polishing is done by several displacements of the car, in each one the head set up an possition to grove or polish, with the use of an easy user program can set up several shapes to be processed.

The equipment provides an auto possitioning bar to adjust the slab aligment, easy to operate and an great help to change material.

The automatic carrosel of tool change have an cover, that one can be open manualy to change abrasives or open with the proximity of motor to change the tool by Iso format.

With the auto lubrification the operator dont need to prevent those.

Technical Features

✓ Working Bench with start length of 145,1/2 inch / 3,7 meters

✓ THE WORKING LENGTH IS CHANGABLE BY THE BRIDGE CHOOSE

✓ Polishing length capacity – 137,1/2 in / 3,5 mt (start on)

✓ Grinding and polish abilities

✓ Carrosel Tool change with 8 supports

✓ Diameter of the plates permissible – 4,5 in / 12 cm

✓ Maximum thickness height – 4,5 in / 12 cm

✓ High revolution 6,000rpm with water passage

spindle with Iso tool auto changer

✓ Power of main motor – 5 Kw / 7,5 Hp

✓ Approximate minimum weight – 9700 lbs / 4,400 Kg

✓ Maximum height required for operation – 74,3/4 in / 1,9 mt

✓ Cutting displacement velocity’s – 20 or 37 mt/min.

✓ Minimum peripheral speed for polishing – by inverter

( can set up in the easy user control )

✓ Monoframe 1st layer protection with hot zinc